- Joined

- Jan 15, 2013

- Messages

- 1,066

- Reaction score

- 1,281

Part 1

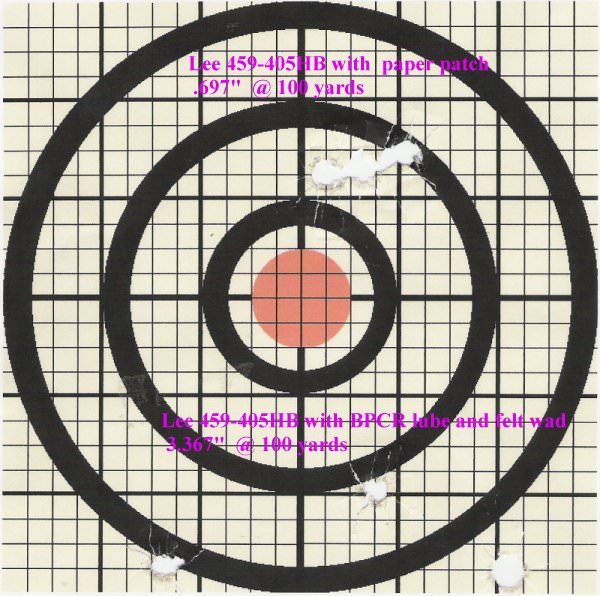

Here is some very poor quality pictures and a description of how to wrap a bullet; sorry I am not a pro at writing.

Before I got to this point, I poured probably 200 bullets to get 75 perfect ones. I grade them for looks and weight. Any bullets with visible flaws are melted again and every good bullet that I keep is +or - 1.0 grains of the target weight sometimes I get even pickyer and go for +- .5 This gives me a constant product, AKA bullet, compare that to TC maxiballs or maxihunters. The lead I use is from a company called Rotometal. I get the pure lead, and it measures right at 6 to 7 BHN on my hardness tester. I used to use a bottom pour lee production pot for pouring lead. I quit using the bottom pour because the bullets didn't come out like I wanted. I went to ladle pouring the bullets and the bullets come out a LOT better and the bullets are filled out better and the weight is more consistent.

Some guys wrap their bullets with wet paper. Most of them have undersized bullets, and are getting a bullet that fits perfectly after wrapping and are not sizing after they wrap the paper on the bullet.

I wrap mine dry and size dry.

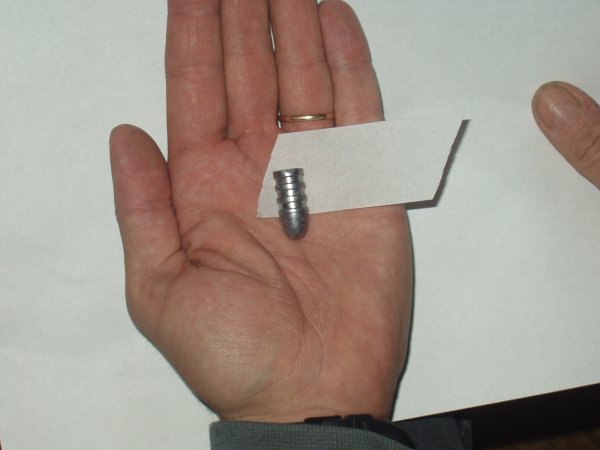

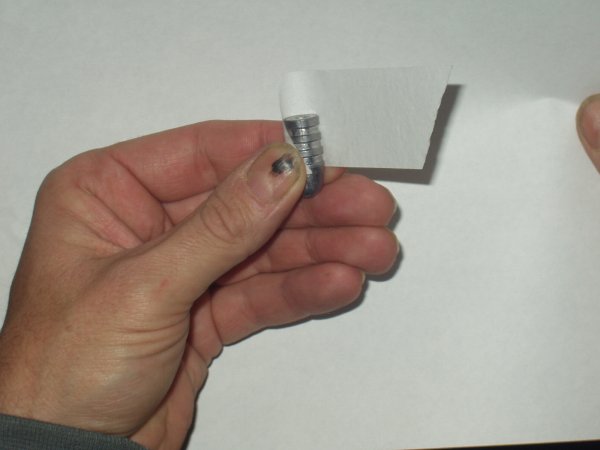

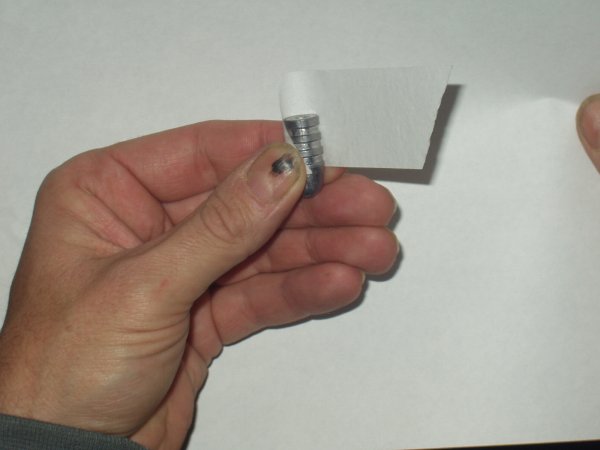

A lot of guys use a bullet wrapping board. I just use my fingers. In this first picture you can see the size and the shape of the paper, the paper adds about .06? to the diameter of the bullet before sizing with the paper I am now using.

In these picture you can see the way I am starting the bullet into the wrap.

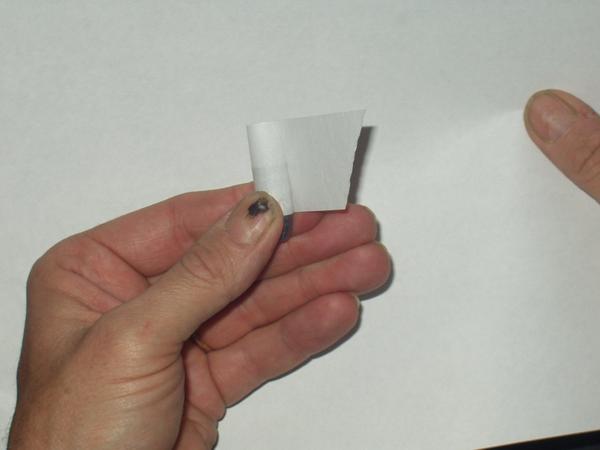

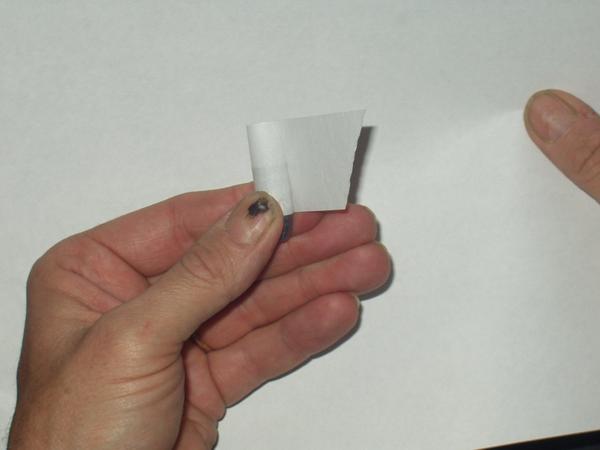

As I roll the bullet on I keep the paper tight as I can. When the paper rolls all the way on the two ends should meet and not overlap.

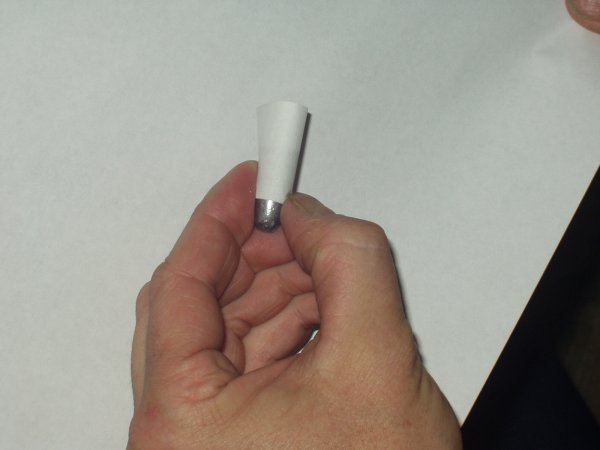

When I get the ends to meet I start to twist the tail.

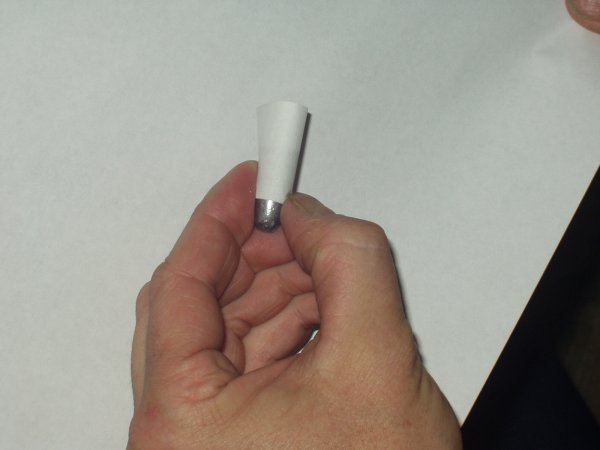

With a hollow base bullet you can then push the tail into the base of the bullet. This picture is quite blurry sorry.

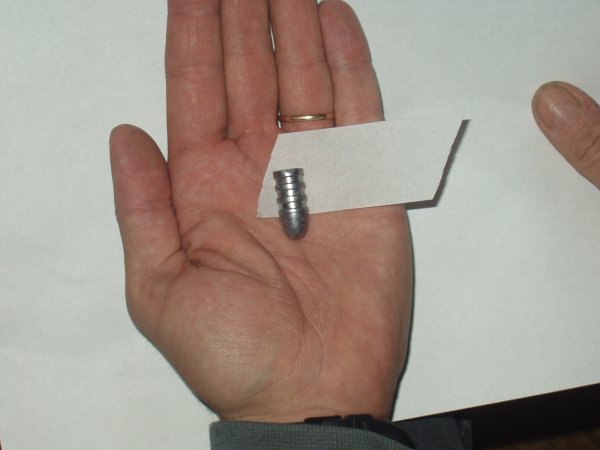

When I get to this point I run them through the sizer die and this is what the finished bullet looks like.

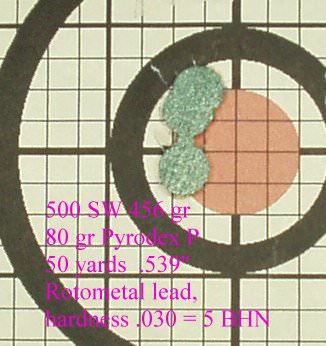

This next one is a Lee C-501-440-RF AKA the Lee 500 S&W bullet.

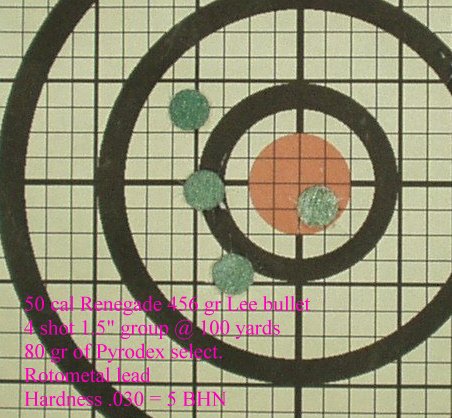

This last one is a RCBS north south skirmish bullet.

I use 9# onion skin paper with 25% cotton. This paper is very difficult to get now. It can still be found but it tough and expensive.

This company used to have it but now they have 9# onion skin but it is wood not cotton. I have tested a little of it and it seems like it shoots the same. It might be more abrasive but I have not determined that yet.

https://www.thepapermillstore.com/paper ... -ream.html

On to Part 2

Here is some very poor quality pictures and a description of how to wrap a bullet; sorry I am not a pro at writing.

Before I got to this point, I poured probably 200 bullets to get 75 perfect ones. I grade them for looks and weight. Any bullets with visible flaws are melted again and every good bullet that I keep is +or - 1.0 grains of the target weight sometimes I get even pickyer and go for +- .5 This gives me a constant product, AKA bullet, compare that to TC maxiballs or maxihunters. The lead I use is from a company called Rotometal. I get the pure lead, and it measures right at 6 to 7 BHN on my hardness tester. I used to use a bottom pour lee production pot for pouring lead. I quit using the bottom pour because the bullets didn't come out like I wanted. I went to ladle pouring the bullets and the bullets come out a LOT better and the bullets are filled out better and the weight is more consistent.

Some guys wrap their bullets with wet paper. Most of them have undersized bullets, and are getting a bullet that fits perfectly after wrapping and are not sizing after they wrap the paper on the bullet.

I wrap mine dry and size dry.

A lot of guys use a bullet wrapping board. I just use my fingers. In this first picture you can see the size and the shape of the paper, the paper adds about .06? to the diameter of the bullet before sizing with the paper I am now using.

In these picture you can see the way I am starting the bullet into the wrap.

As I roll the bullet on I keep the paper tight as I can. When the paper rolls all the way on the two ends should meet and not overlap.

When I get the ends to meet I start to twist the tail.

With a hollow base bullet you can then push the tail into the base of the bullet. This picture is quite blurry sorry.

When I get to this point I run them through the sizer die and this is what the finished bullet looks like.

This next one is a Lee C-501-440-RF AKA the Lee 500 S&W bullet.

This last one is a RCBS north south skirmish bullet.

I use 9# onion skin paper with 25% cotton. This paper is very difficult to get now. It can still be found but it tough and expensive.

This company used to have it but now they have 9# onion skin but it is wood not cotton. I have tested a little of it and it seems like it shoots the same. It might be more abrasive but I have not determined that yet.

https://www.thepapermillstore.com/paper ... -ream.html

On to Part 2