- Joined

- Mar 19, 2016

- Messages

- 122

- Reaction score

- 59

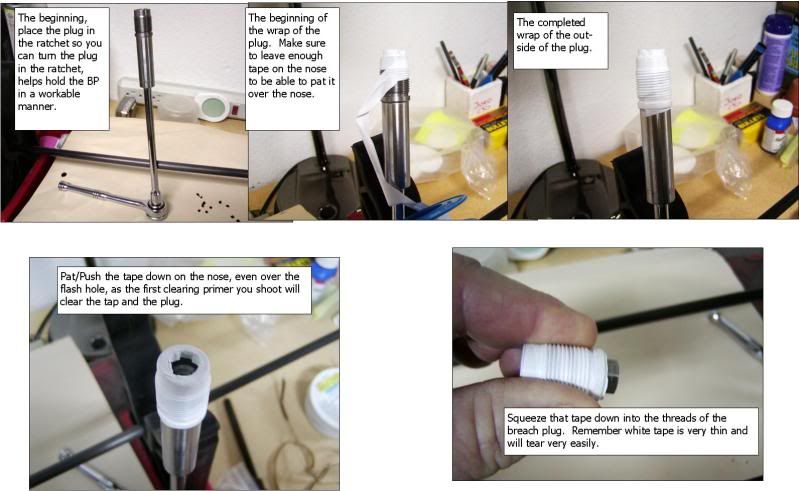

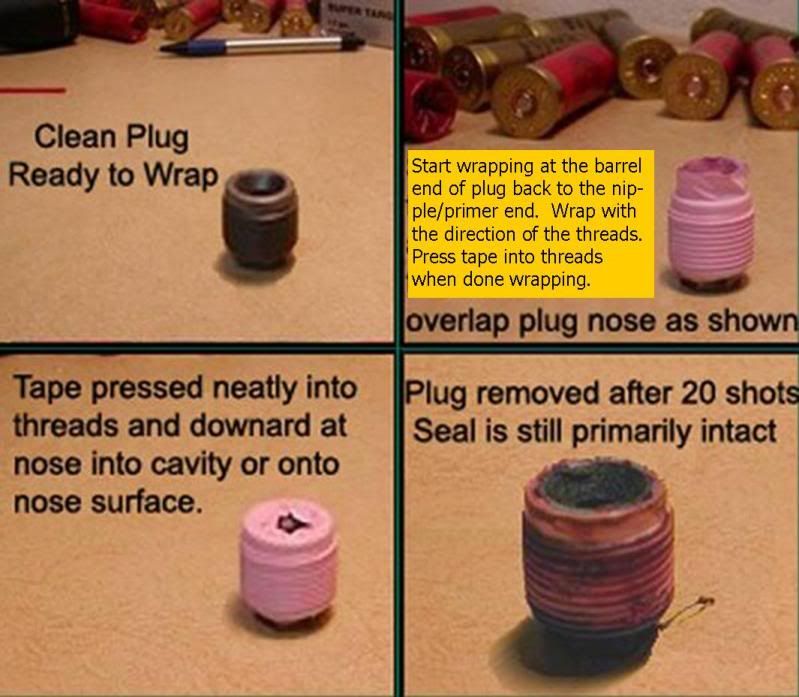

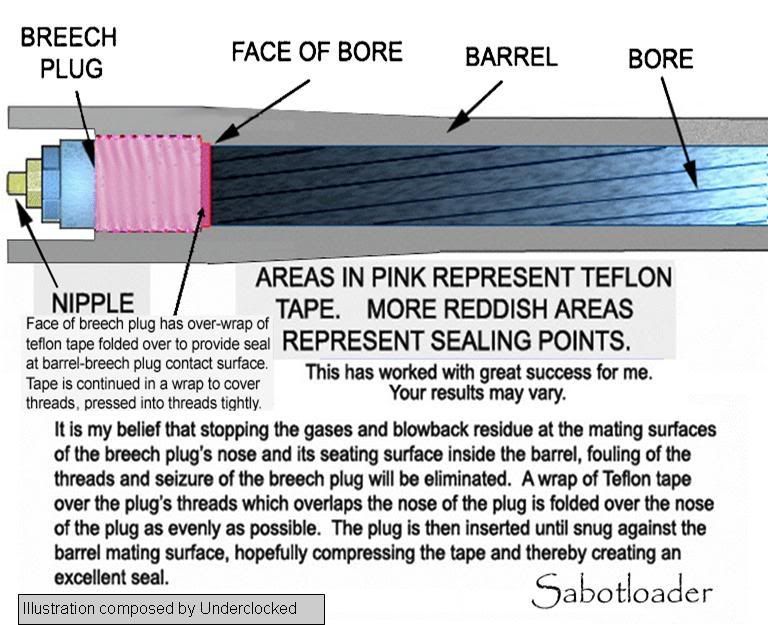

Been reading quite a bit of discussion on proper products for MZ breechplug threads. I assume that the issue is mainly for prevention of seizing or galling from residue working its way into the threads. Many suggest using teflon tape, is this in addition to a anti-seize product? In the Power Generation Industry it is common to only use a few wraps of teflon tape followed up with a light coating of teflon joint compound over the tape. This provides a HIGH PRESSURE seal for the commonly used Tapered threaded instrumentation connections and ensures that the joint can be taken apart. Removing either of these products would not be any more messy than a anti-sieze product and works very well. I believe the breech plug threads are of a non-taperd design and there for harder to seal than a taperd NPS (nominal pipe size) thread design. The teflon tape and teflon thread sealant really works great on non-ferrous materials (Stainless to Stainless) which are the hardest to seal. Good teflon tape and sealant is free of chlorides which can attack Stainless Steel for long term use.