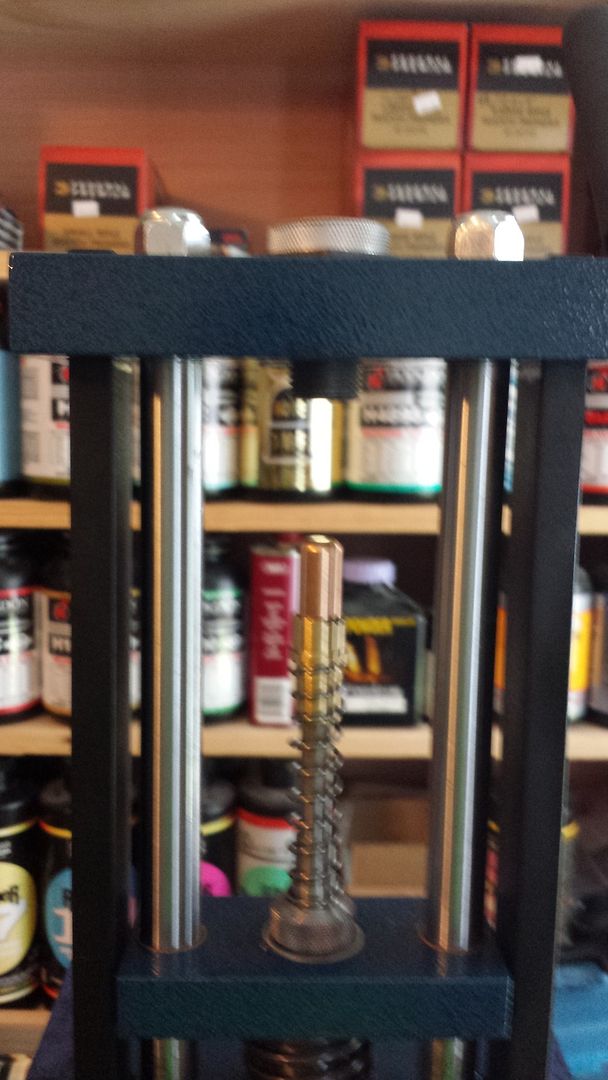

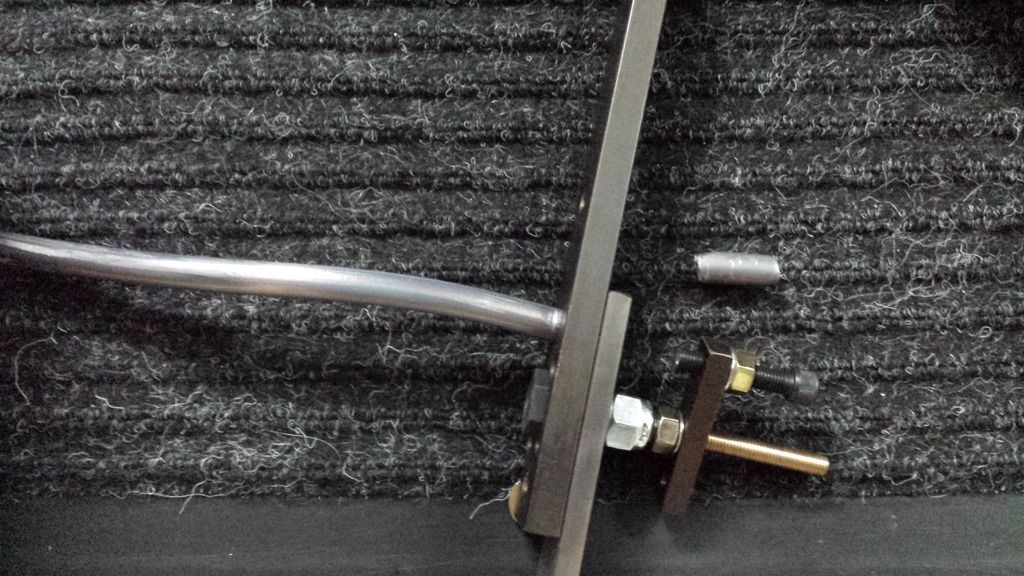

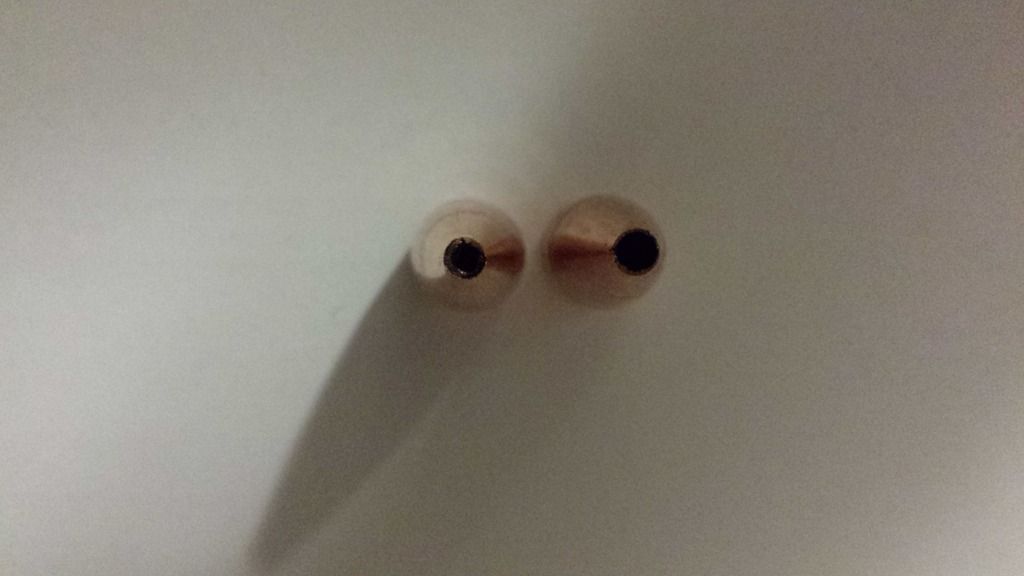

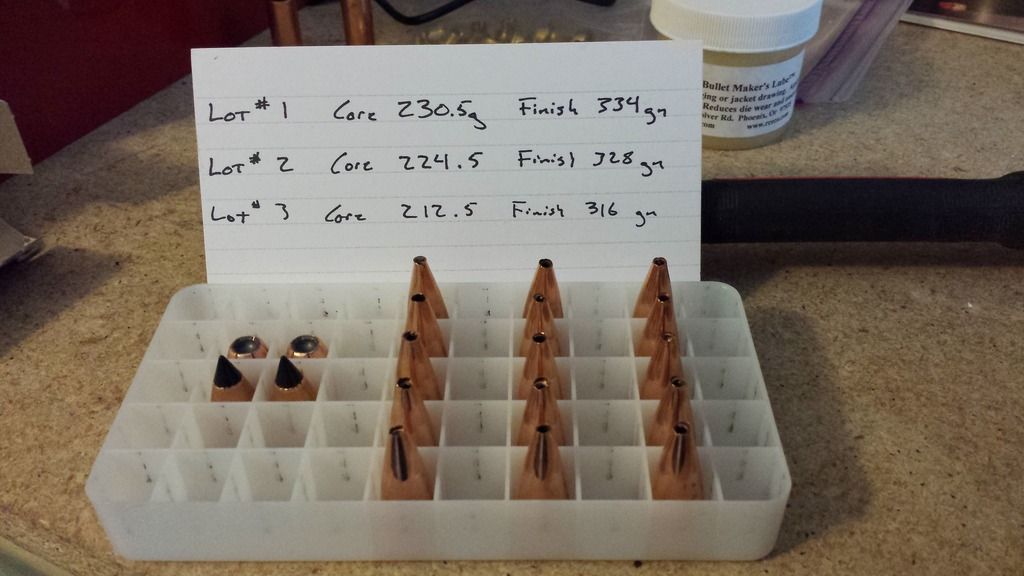

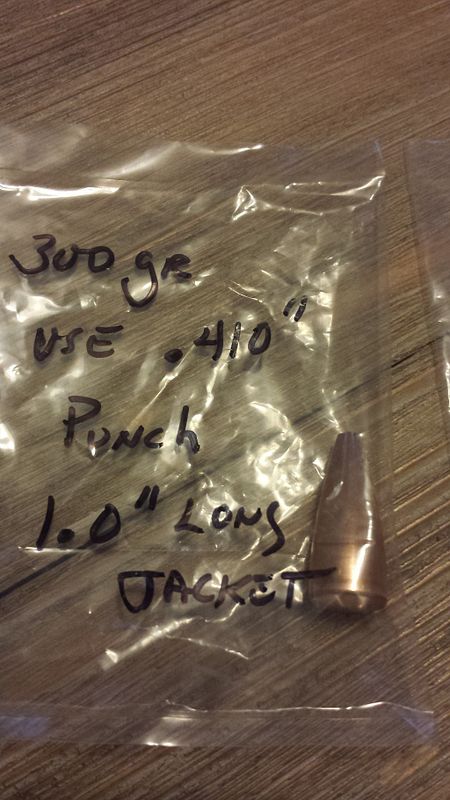

I just received a set of swaging dies I custom ordered a little over a year ago to make bullets for my smokeless muzzleloader. These are an opent tip match (OTM) design. They probably have a little lower BC than the Parker MH bullets I have been shooting but I can make them much more cheaply.

It has been a little bit of a learning curve but I have made a few this weekend and have a few I feel good about. Picture of blems I made two days ago; used them today to see if I could get them to hit paper and fly point forward. From left to right:

1. 291.1gn

2. 317.7gn

3. 309.5gn

4. 321.5gn

5. 329.5gn

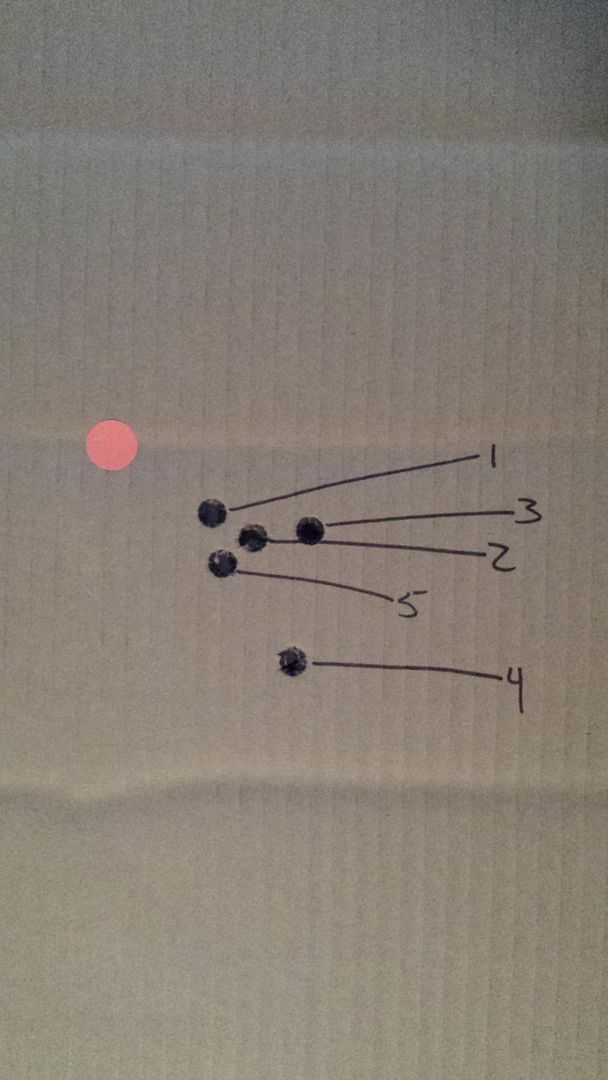

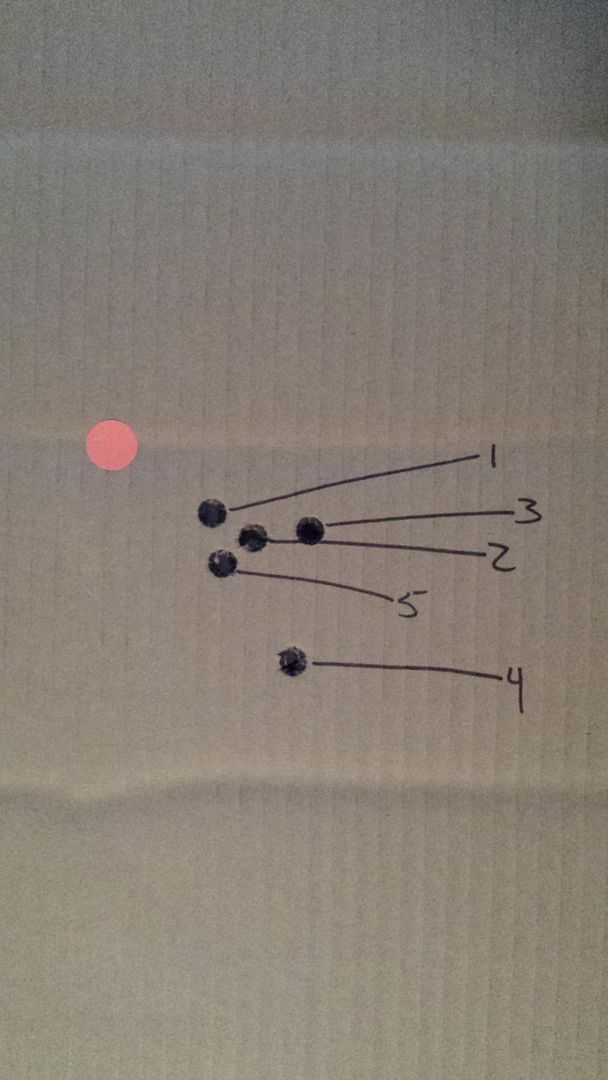

I spent the morning making some barricades to train on for the upcoming DMR match, helped clean the house, then headed to the range to see if I just wasted a month's pay on this project or if I could sleep easy tonight. I measured out six charges of 65gn of IMR4198 and sized a 250gn BE. I swap this scope between guns and don't always remember what it was mounted on or what the correction is to get it zeroed on whatever it is newly riding on. At the range I loaded the 250gn BE and shot it at the large piece of cardboard I was using as a target. I hit 6.2mils left and 4.8mils low so I guess it was on my .308Win last. I dialed on the correction, took a deep breath, and loaded up the 294.1gn bullet then let her fly.

5 prototypes, from 291.1-329.5gn, all over 65gn IMR 4198:

I was curious what shot 4 would do as I miscalculated when I made it and it was pretty much a solid instead of an OTM. It opened the entire cluster to 2.5" with the rest being in 1.5", and the best 3 being .75" or so. This is by no means, scientific, or definitive. Things I feel like I can say at this point:

1: I calculated this bullet design to work in a 1-24" twist or faster. My McGowen is supposed to be a 1-24 (actually closer to 1-23.5" when measured) and while I didn't chrono these today, they are flying point forward and making neat little holes in the target. That means they should work in a stock Savage with sabot or any sabotless gun that is 1-24 or faster so long as muzzle velocity is over 2100fps. The lower your MV the more twist you need.

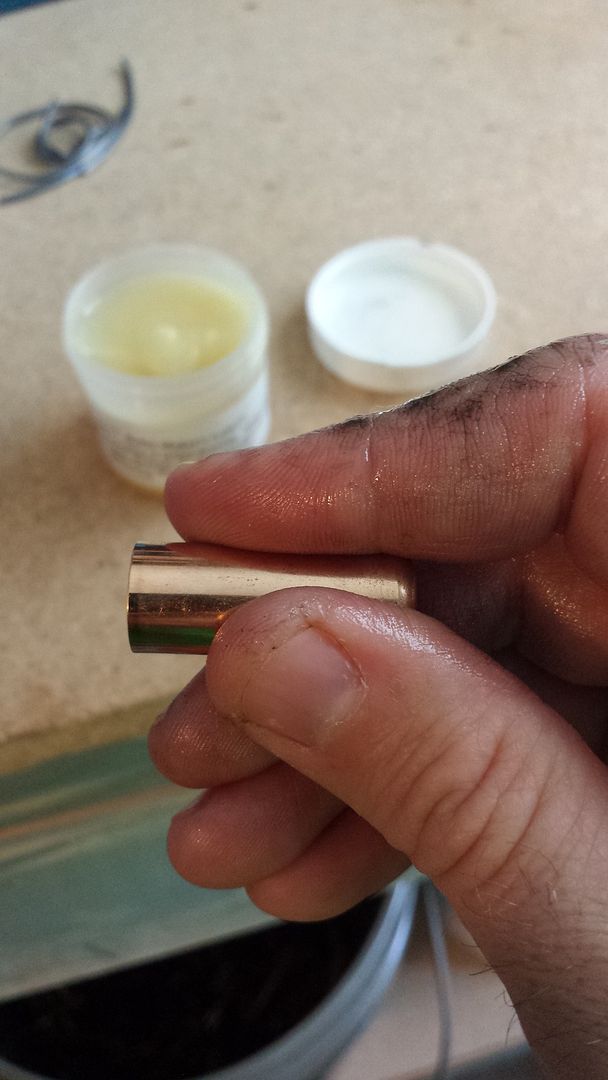

2. I am not worried about the tapered jacket. I didn't anneal these jackets prior to swaging and I did not make any adjustments on my die from where I size BE or MH bullets. These sized with the same effort as anything else and loaded with about the same resistance as a BE or MH.

3. My idea of what would work in regards to bullet design was not completely wrong. The bullet design seems to be fairly forgiving as the bullets have a 40gn or so weight spread and with a single charge shoot to the same relative POI with pretty good precision.

4. In my gun 65gn of IMR 4198 was fine up to the 317gn bullet. I used that same charge for the 321.5gn and 329.5gn but it was a little on the warm side.

It has been a little bit of a learning curve but I have made a few this weekend and have a few I feel good about. Picture of blems I made two days ago; used them today to see if I could get them to hit paper and fly point forward. From left to right:

1. 291.1gn

2. 317.7gn

3. 309.5gn

4. 321.5gn

5. 329.5gn

I spent the morning making some barricades to train on for the upcoming DMR match, helped clean the house, then headed to the range to see if I just wasted a month's pay on this project or if I could sleep easy tonight. I measured out six charges of 65gn of IMR4198 and sized a 250gn BE. I swap this scope between guns and don't always remember what it was mounted on or what the correction is to get it zeroed on whatever it is newly riding on. At the range I loaded the 250gn BE and shot it at the large piece of cardboard I was using as a target. I hit 6.2mils left and 4.8mils low so I guess it was on my .308Win last. I dialed on the correction, took a deep breath, and loaded up the 294.1gn bullet then let her fly.

5 prototypes, from 291.1-329.5gn, all over 65gn IMR 4198:

I was curious what shot 4 would do as I miscalculated when I made it and it was pretty much a solid instead of an OTM. It opened the entire cluster to 2.5" with the rest being in 1.5", and the best 3 being .75" or so. This is by no means, scientific, or definitive. Things I feel like I can say at this point:

1: I calculated this bullet design to work in a 1-24" twist or faster. My McGowen is supposed to be a 1-24 (actually closer to 1-23.5" when measured) and while I didn't chrono these today, they are flying point forward and making neat little holes in the target. That means they should work in a stock Savage with sabot or any sabotless gun that is 1-24 or faster so long as muzzle velocity is over 2100fps. The lower your MV the more twist you need.

2. I am not worried about the tapered jacket. I didn't anneal these jackets prior to swaging and I did not make any adjustments on my die from where I size BE or MH bullets. These sized with the same effort as anything else and loaded with about the same resistance as a BE or MH.

3. My idea of what would work in regards to bullet design was not completely wrong. The bullet design seems to be fairly forgiving as the bullets have a 40gn or so weight spread and with a single charge shoot to the same relative POI with pretty good precision.

4. In my gun 65gn of IMR 4198 was fine up to the 317gn bullet. I used that same charge for the 321.5gn and 329.5gn but it was a little on the warm side.