You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Wheel weights

- Thread starter Jokker78

- Start date

Help Support Modern Muzzleloading Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

- Joined

- Jul 7, 2017

- Messages

- 609

- Reaction score

- 416

I have shot a lot of bullets made from wheel weights in sabots with great success.

I use to shoot in a muzzleloader league and in my first year I made several hundred conical slip fit bullets to shoot from lead that I really wasn't sure of the hardness. The first few weeks these bullets shot great but then they started to "age harden" and my 475 grains bullets were not swelling up properly in the barrel and hitting the 25 yard target sideways. Wheel weights will age harden also so use them with Sabots only.

I use to shoot in a muzzleloader league and in my first year I made several hundred conical slip fit bullets to shoot from lead that I really wasn't sure of the hardness. The first few weeks these bullets shot great but then they started to "age harden" and my 475 grains bullets were not swelling up properly in the barrel and hitting the 25 yard target sideways. Wheel weights will age harden also so use them with Sabots only.

Idaholewis

Well-Known Member

- Joined

- Jun 30, 2017

- Messages

- 7,287

- Reaction score

- 10,288

Jokker78 said:If I do take this adventure, it would be to shoot in sabots . 45 Cal bullets.

With Sabots You would be good to go. I have loaded 9-9.5 BHN Maxi balls, and Lyman Great Plains bullets, It definitely wasn’t great, but also wasn’t that horrible, A solid brass Rangerod helps

Let’s Say you were gonna shoot 12 times, if you were to cast those bullets the day before you shot, they probably wouldn’t be that horrible to load? But let them sit around for awhile, and you better have eaten your Wheaties! Lead age hardens, and REALLY changes the way they load

- Joined

- Dec 24, 2009

- Messages

- 15,021

- Reaction score

- 6,882

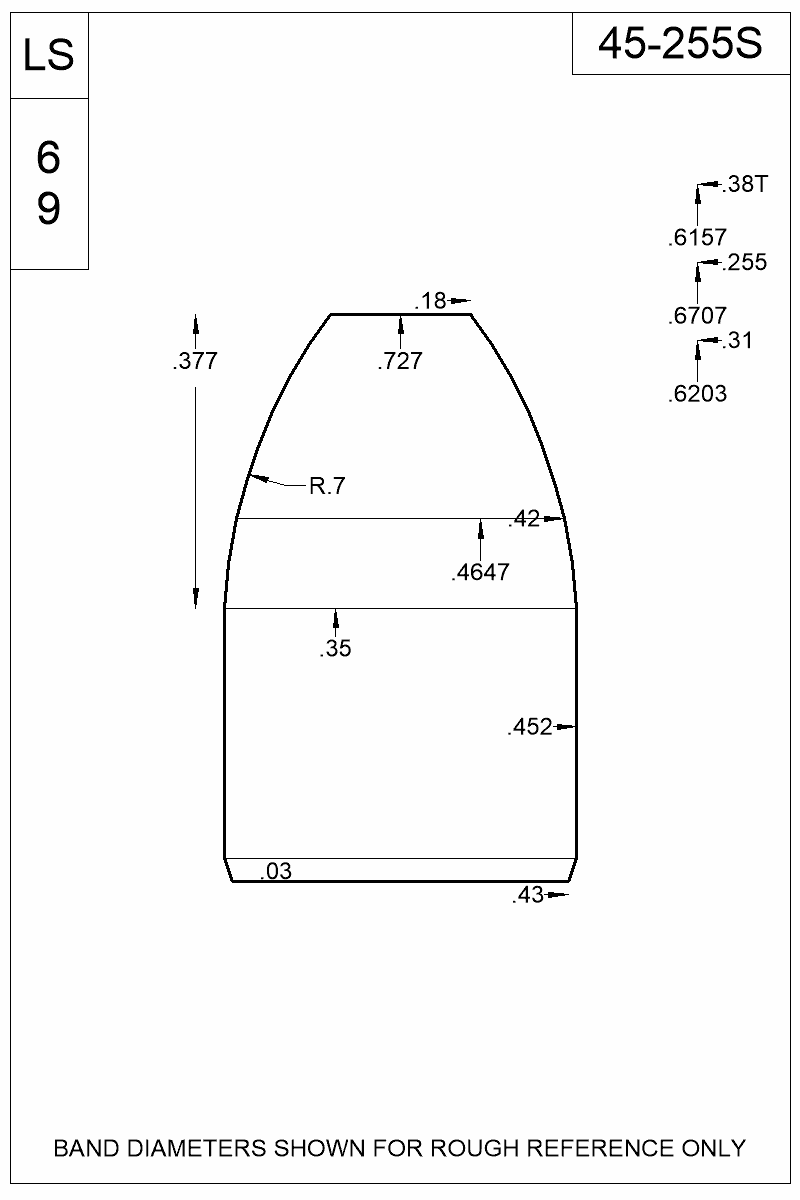

1 or 2 companies offer a "sabot bullet" mold. LBT and Accurate IIRC. WW lead would be just fine for that application.

Accurate has several actually. They look a bit like this one. Ive seen them as low as 230gr. Advertised weight is based on WW.

Accurate has several actually. They look a bit like this one. Ive seen them as low as 230gr. Advertised weight is based on WW.

- Joined

- Dec 24, 2009

- Messages

- 15,021

- Reaction score

- 6,882

Someone on another board had this mold made to mimic a SST

In regards to lead "age hardening" I have not noticed this happen with pure lead, I think it is more something that happens with alloys.

The best use I have found for wheel weights is to make fishing jigs. Another use I had was melting it into ingots and trading it with a reloader for pure lead 1 for 1. I gleaned over 800 lbs of pure lead that way.

The best use I have found for wheel weights is to make fishing jigs. Another use I had was melting it into ingots and trading it with a reloader for pure lead 1 for 1. I gleaned over 800 lbs of pure lead that way.

- Joined

- Jan 1, 2013

- Messages

- 1,982

- Reaction score

- 800

Lead is a funny thing, Take that ~ 10-12 bhn WW lead, and water quench when you drop from the mold, the BHN will probably be ~18-22. There are a ton of things that can affect the outcome.

Pure lead takes a lot hotter pot to hit the melting point, than an antimony mix. A lot of the theory of add tin to better fill the mold, can also be achieved by running a hotter pot.

A lot of guys look for a surface color. usually a yellowish, or straw color for optimum temp. too hot then becomes a blueish and surface oxidation starts. I find I run my Lee 4- 20 almost wide open when using pure (and pouring big lead in bulk) but with an antimony mix, I back off to ~650-700 f.

Linotype starts to melt at about 460 deg. pure lead melts at 621.

Pure lead takes a lot hotter pot to hit the melting point, than an antimony mix. A lot of the theory of add tin to better fill the mold, can also be achieved by running a hotter pot.

A lot of guys look for a surface color. usually a yellowish, or straw color for optimum temp. too hot then becomes a blueish and surface oxidation starts. I find I run my Lee 4- 20 almost wide open when using pure (and pouring big lead in bulk) but with an antimony mix, I back off to ~650-700 f.

Linotype starts to melt at about 460 deg. pure lead melts at 621.

- Joined

- Jul 7, 2017

- Messages

- 609

- Reaction score

- 416

As flounder has already mentioned, pure lead does not age harden.

- Joined

- Jul 7, 2017

- Messages

- 609

- Reaction score

- 416

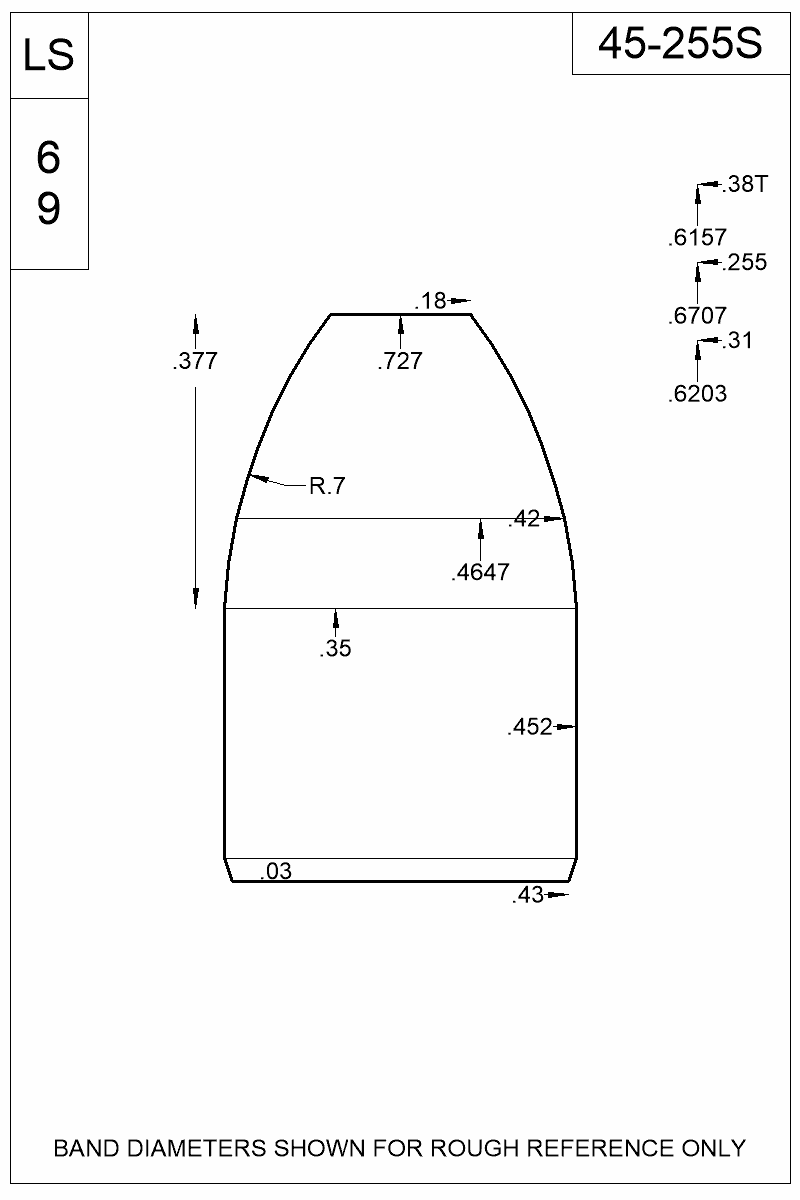

Mountain Molds made me this mold to cast 40 caliber 225 Grain Bullet From Wheel Weights . In 10+ years I have taken several Deer out to 150 yards using both 50 caliber(blue sabot) and 45 caliber(brown sabot). Unfortunatly Mountain Molds no longer makes molds for smooth sided bullets.

Attachments

- Joined

- Sep 21, 2006

- Messages

- 167

- Reaction score

- 8

usually .0005"- .001" depending on nominal diameter. The bigger bullets can grow .001" after a few months52Bore said:Curious as to how much a ww bullet grows?