- Joined

- Dec 26, 2010

- Messages

- 3,519

- Reaction score

- 1,472

I messaged Idaholewis asking him his cleaning procedure for his sidelocks and the detailed response that I got made me want to share it, with his permission.

Here it is:

Sure, When i walk in the Door everything is Routine I guess that comes with Shooting them a Million Times LOL

I guess that comes with Shooting them a Million Times LOL

When i walk through the Door after Shooting, i push the Wedge Key out of the Stock, and Lift the Barrel out, Set the Stock Aside. I then Pull the Nipple (I use a TC 3 N 1 Tool) I Run my Water in the Feed Bucket (Just Warm Water)

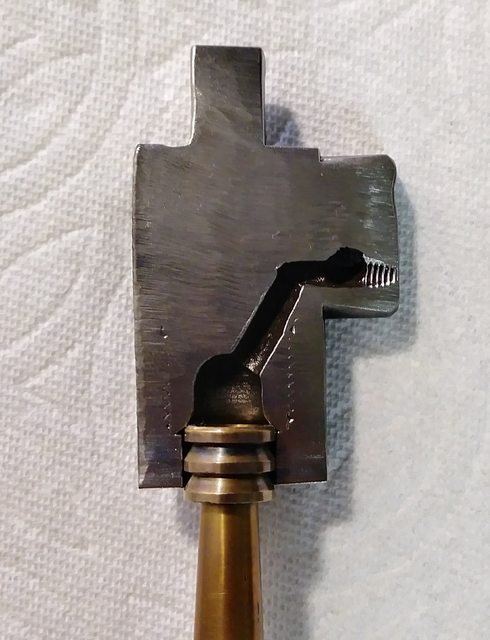

Here is the TC Tool i use, and ABSOLUTELY Swear By, It has a Nipple Wrench Built in, it is a Little Hammer for Pecking the Wedge Key over, then you simply flip the Tool around and use the Little Claws to Get under the Wedge Key to Finish Removing it, AWESOME little Tool that i use EVERYTIME i Shoot. I did have to make a Few Little Modifications to Both of mine though (I have 2 of these, one for my Truck, and 1 in my House) The Nipple Wrench was a Little to Tight so i had to Open the Gap Slightly, I used my Dremel with a Cutter/Grinding Wheel, And the Claws were also a Little Tight, i used the Dremel to Open the Claws a Little as Well, Both we’re SIMPLE Fixes! Just go slow, and Check fit often til you get it. Maybe i got 2 Flukes that were Tight?

Here it is:

Sure, When i walk in the Door everything is Routine

When i walk through the Door after Shooting, i push the Wedge Key out of the Stock, and Lift the Barrel out, Set the Stock Aside. I then Pull the Nipple (I use a TC 3 N 1 Tool) I Run my Water in the Feed Bucket (Just Warm Water)

Here is the TC Tool i use, and ABSOLUTELY Swear By, It has a Nipple Wrench Built in, it is a Little Hammer for Pecking the Wedge Key over, then you simply flip the Tool around and use the Little Claws to Get under the Wedge Key to Finish Removing it, AWESOME little Tool that i use EVERYTIME i Shoot. I did have to make a Few Little Modifications to Both of mine though (I have 2 of these, one for my Truck, and 1 in my House) The Nipple Wrench was a Little to Tight so i had to Open the Gap Slightly, I used my Dremel with a Cutter/Grinding Wheel, And the Claws were also a Little Tight, i used the Dremel to Open the Claws a Little as Well, Both we’re SIMPLE Fixes! Just go slow, and Check fit often til you get it. Maybe i got 2 Flukes that were Tight?