Idaholewis

Well-Known Member

- Joined

- Jun 30, 2017

- Messages

- 7,287

- Reaction score

- 10,288

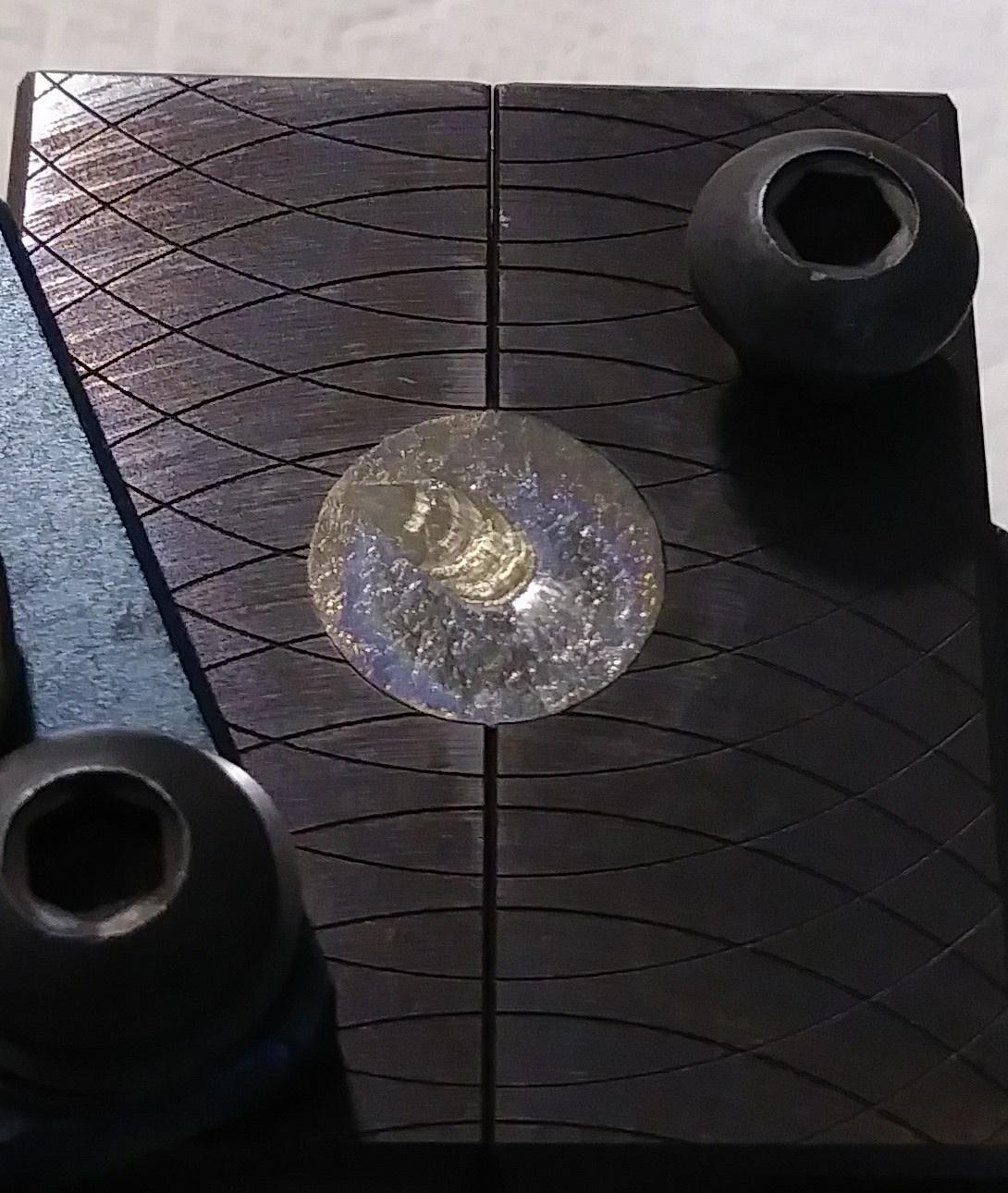

When you get everything running right, Your Alloy/Lead to the Desired Temp, and your Mold to it’s perfect Temp. When you Start Casting, make sure and Puddle up a Nice Big Sprue on Top, This makes a BIG difference in Base Fillout.

Like this

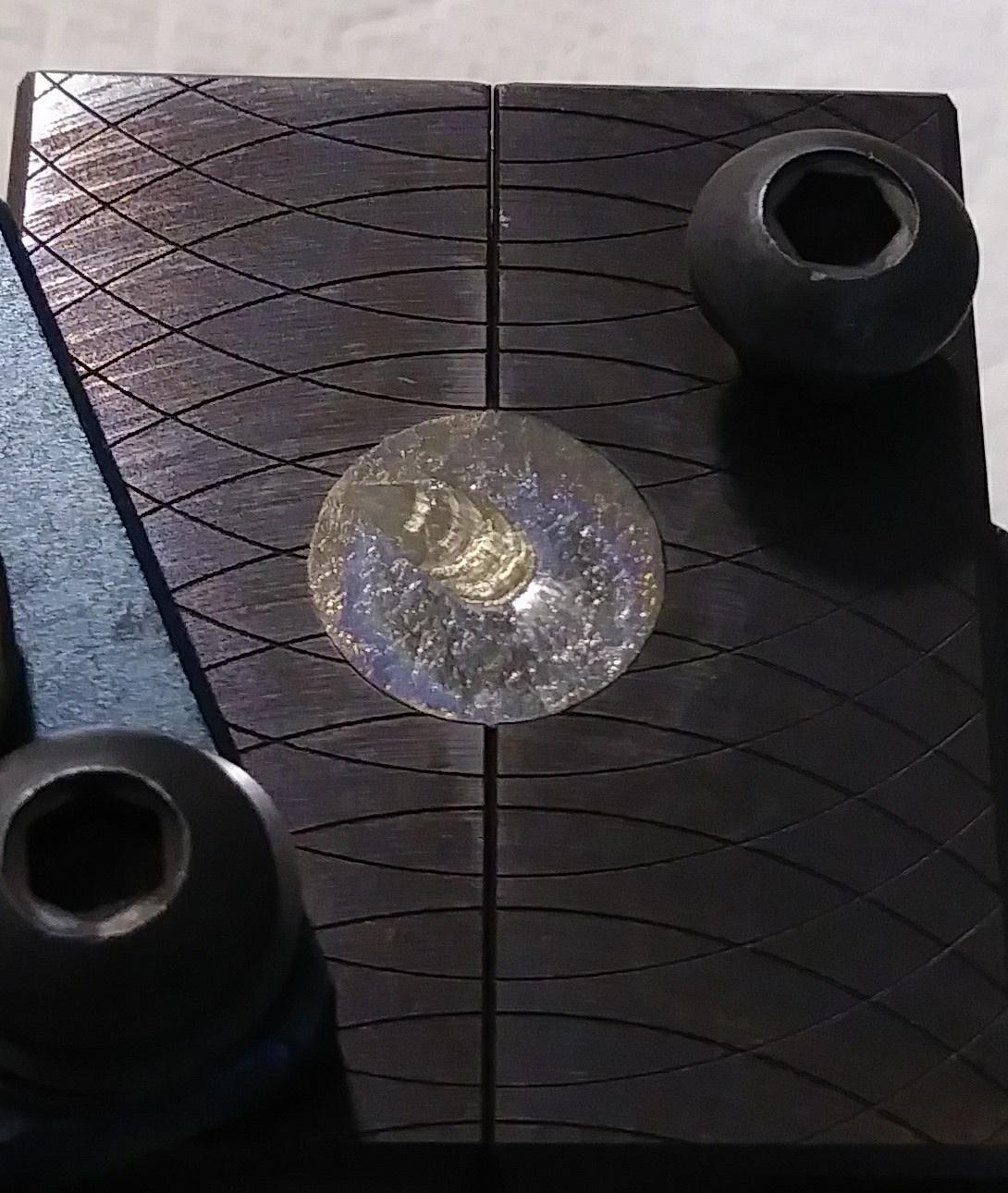

Cut the Sprue within a Few Seconds of it Solidifying, DON’T Wait to long! I hear some of you mention 30-45 Seconds, that is WAY WAY WAY to long in my Experience. Quick as you Cut the Sprue, Dump the Bullet, and QUICKLY Re-fill the Mold again.

This process to HIGH Quality Bullets is a Heat, Speed, and Rhythm thing. PRACTICE PRACTICE PRACTICE, You will get it Down

After the Sprue has been Cut, you will find a PERFECTLY Filled Out, RAZOR SHARP Bullet Base like this. Without the Need for Compression

Simply Put, By following my Content here, You can’t make a Nicer Bullet. ”Mirrors of the Mold”

This was a Small, Quick Run of my New #50-415i Bullet to test in my Soon to be 1-24 Twist RICE Barrel. My Keep Rate was 100% here All 22 Bullets Weigh 429.5 to 429.8

All 22 Bullets Weigh 429.5 to 429.8

Like this

Cut the Sprue within a Few Seconds of it Solidifying, DON’T Wait to long! I hear some of you mention 30-45 Seconds, that is WAY WAY WAY to long in my Experience. Quick as you Cut the Sprue, Dump the Bullet, and QUICKLY Re-fill the Mold again.

This process to HIGH Quality Bullets is a Heat, Speed, and Rhythm thing. PRACTICE PRACTICE PRACTICE, You will get it Down

After the Sprue has been Cut, you will find a PERFECTLY Filled Out, RAZOR SHARP Bullet Base like this. Without the Need for Compression

Simply Put, By following my Content here, You can’t make a Nicer Bullet. ”Mirrors of the Mold”

This was a Small, Quick Run of my New #50-415i Bullet to test in my Soon to be 1-24 Twist RICE Barrel. My Keep Rate was 100% here

All 22 Bullets Weigh 429.5 to 429.8

All 22 Bullets Weigh 429.5 to 429.8