- Joined

- Sep 23, 2019

- Messages

- 256

- Reaction score

- 243

What is the best way to break in a new rifle barrel?

This is gonna be similar to what Tom just Linked, This is Montana Extreme’s Version of JB’s Bore Paste. I have used this Stuff with STELLAR Results, I do this with EVERY New Rifle. Cut some Strips of 0000 Steel Wool and Place over a Patched Jag, Get a TIGHT Fit, Add this Compound and Give the Bore about 100 Strokes, 1 Stroke being all the Way down, and Back to Exit the Bore, That is 1 Stroke

This is gonna be similar to what Tom just Linked, This is Montana Extreme’s Version of JB’s Bore Paste. I have used this Stuff with STELLAR Results, I do this with EVERY New Rifle. Cut some Strips of 0000 Steel Wool and Place over a Patched Jag, Get a TIGHT Fit, Add this Compound and Give the Bore about 100 Strokes, 1 Stroke being all the Way down, and Back to Exit the Bore, That is 1 Stroke

Edmehlig, do you mean a regular or slotted jag? And do I need to get the round 0000 steal wool pads? How much of the wool pad do I use?Here’s a post from IdahoLewis

Here’s another Product i use, and Swear ByThis is gonna be similar to what Tom just Linked, This is Montana Extreme’s Version of JB’s Bore Paste. I have used this Stuff with STELLAR Results, I do this with EVERY New Rifle. Cut some Strips of 0000 Steel Wool and Place over a Patched Jag, Get a TIGHT Fit, Add this Compound and Give the Bore about 100 Strokes, 1 Stroke being all the Way down, and Back to Exit the Bore, That is 1 Stroke

Nov 27, 2019Report

Like+ QuoteReply

I done like you suggested. I got me some 0000 steel wool. I oiled it well with ballistol over a patch. I ran it in all the way and out 105 strokes. I went to my range (now that deer season is over) and tried 60 grains of 3f goex and 65 grains. 4 shots each @ 50 yards. The older guys at the club talked me into the wet shooting patch. I'm not sold on that because you and me know it is contaminating some of the powder. They told me to only use my mink oil hunting. 4 inch groups and low and to the right. Tomorrow, if it is not raining, I'm going to try the mink oil with the same charges. I'm also thinking real serious about getting the folding rear blade sight with matching small white bead front sight from Lyman. It's only $30 bucks plus $6 shipping. I don't trust the primitive because the front blade is so wide and it doesn't fill the width of the rear. However, I am sand bagged propped really well over my shooting box and not moving at all. Man I wish I could shoot a pattern like you do!I started a Thread on this Quite some time ago in the “Long Range Hunting & Target Shooting” Sub forum below. This is Lee Shaver’s Process, Lee is a 2 Time World Champion, Along with NUMEROUS other Records, and Wins. I do this to EVERY Rifle i own, Before they are Ever Shot for the 1st time. You guy’s see my Results on here. Would my Rifles have shot as well as they do without doing this? I don’t know? I haven’t tried, nor do i intend to. This Process has always made good sense to me, i have followed it to the T, You guy’s see my Results on here, They Don’t lie

Lee Shaver’s Break-in Procedure

Excerpt from “Breaking In a Barrel” by Lee Shaver:

Several years ago, I developed a process for breaking-in barrels for lead bullet use

that eliminated the afternoon of shooting and cleaning with jacketed bullet. It

began because I would occasionally have to get bad leading out of a barrel for a

customer, and when you charge what a gunsmith must charge to stay in business

you don’t want to spend an afternoon scrubbing the lead out of a customer’s gun.

And I’m sure the customer would rather not pay for said services.

What I learned was that when scrubbing lead out of a barrel, I could run a tight oily

patch through a few times and then take the patch off the jag. I would then unroll a

little 0000 steel wool and cut a piece the size of the patch. Place that over the

patch and then run it all through together. (The proper fit is when you have to

bump the rod a few times with the palm of your hand to get it started in the bore.)

When you shove that steel wool over a patch through the bore of a badly leaded

barrel, it may sound like paper tearing as the lead is ripped out of the barrel in a

pass or two. I can clean the lead out of the worst barrel in about ten or fifteen

minutes that way, and an average leaded barrel will be clean in a few strokes.

After using this technique for a while, I began to notice that the rifles that I was de-

leading that way seemed to lead less afterwards, which got me to thinking. We use

fine steel wool on the outside of old guns all the time to do some cleaning or spot

rust removal, and it does not damage the surface of the steel. It just scrubs it.

Which lead me to consider the fact that we are trying to break in a barrel by

smoothing the surface without cutting, and it seems to me that process would go

much quicker if we used something on the inside of the bore that was closer to the

hardness of the barrel instead of lead or copper. So I started trying the steel wool

and oiled patch technique on new barrels before shooting them. I use it about as

tight as I can get in the bore and wear out a steel wool pad or two in about 15

minutes, then I go and shoot the rifle.

How well does it work you might ask? On a few occasions, I have built a new rifle

and taken it to a match without ever having fired the rifle. All have performed

flawlessly in their first match and several times I won the match or set a record

with them. On one occasion, I set a new 300 yard range record with the first 13

shots out of a barrel. This method has become a service we offer to our customers

here in the shop and I have shared the technique many times with others.

So the next time you get ready to shoot that new rifle, just remember it is important

to break in a barrel properly, but if the operation you are doing to the barrel cuts –

it is not breaking it in. It may be making the barrel smoother, but to break the

barrel in you need to polish the bore by burnishing not cutting either by shooting it

or scrubbing it.

Lee Shaver

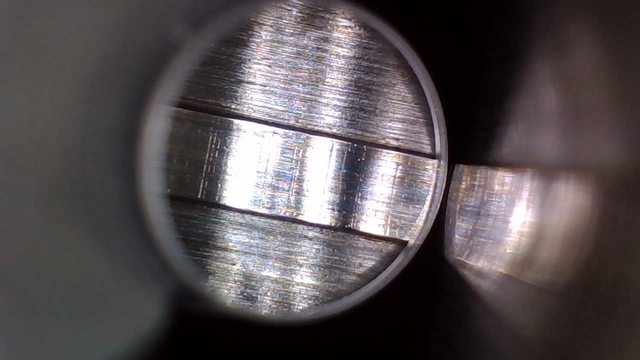

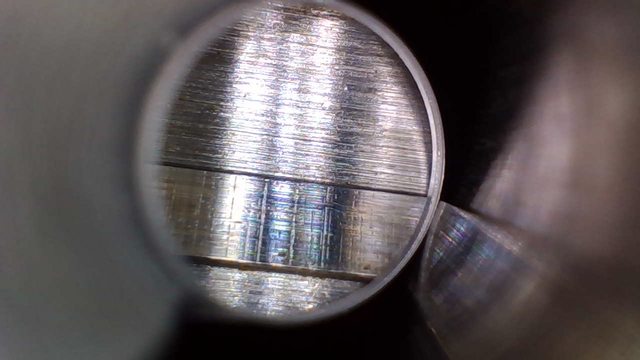

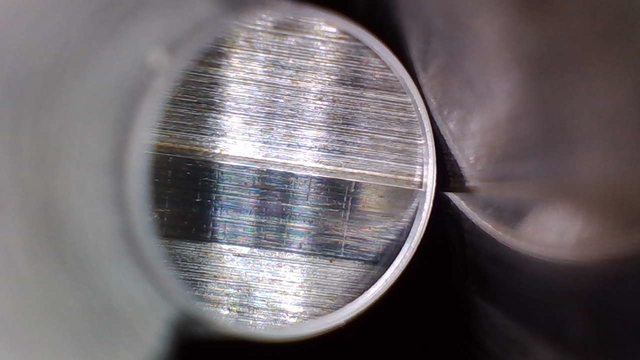

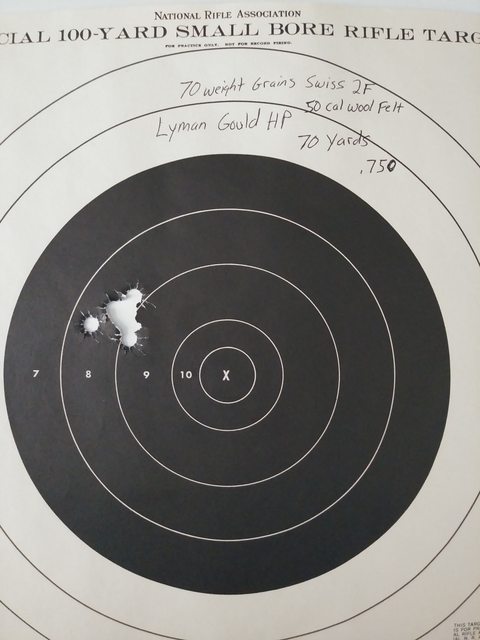

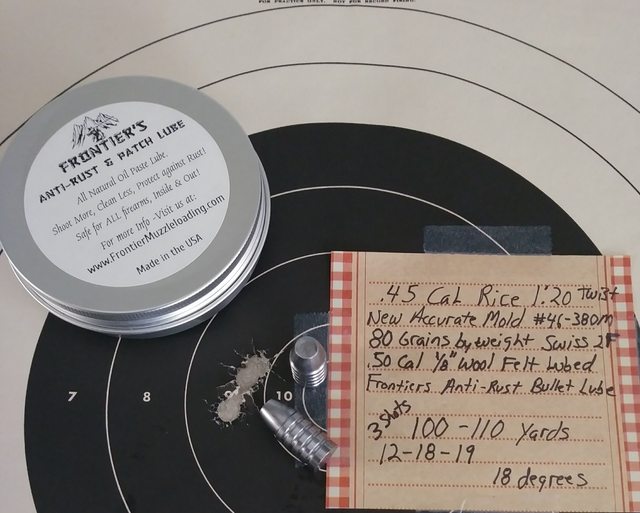

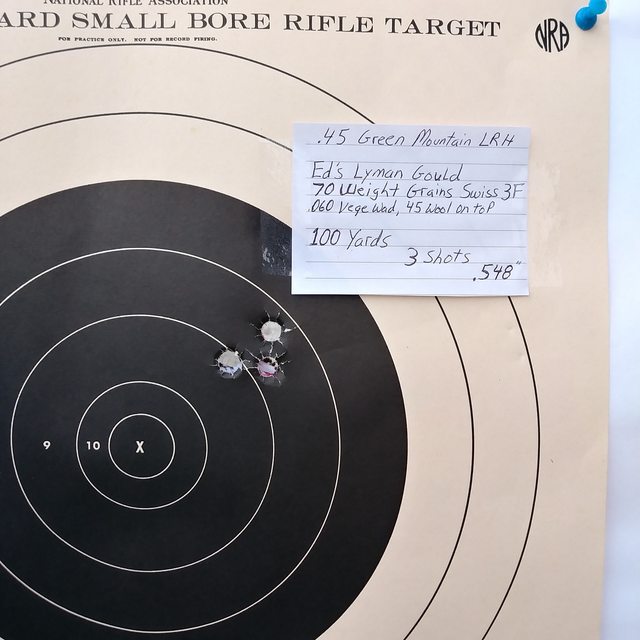

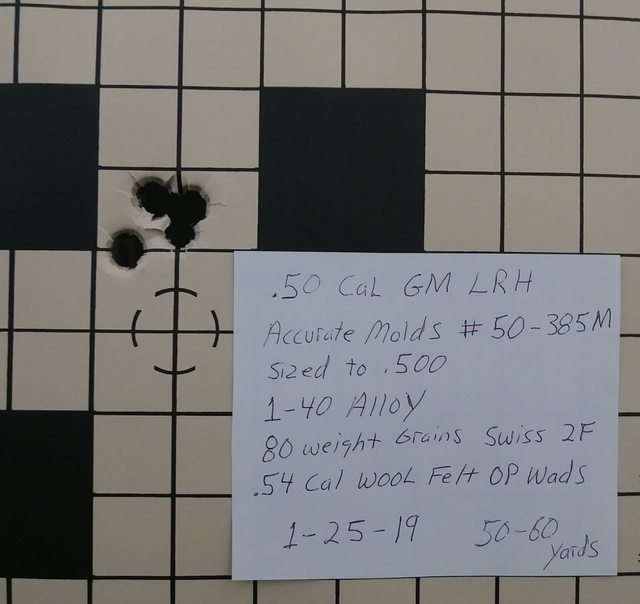

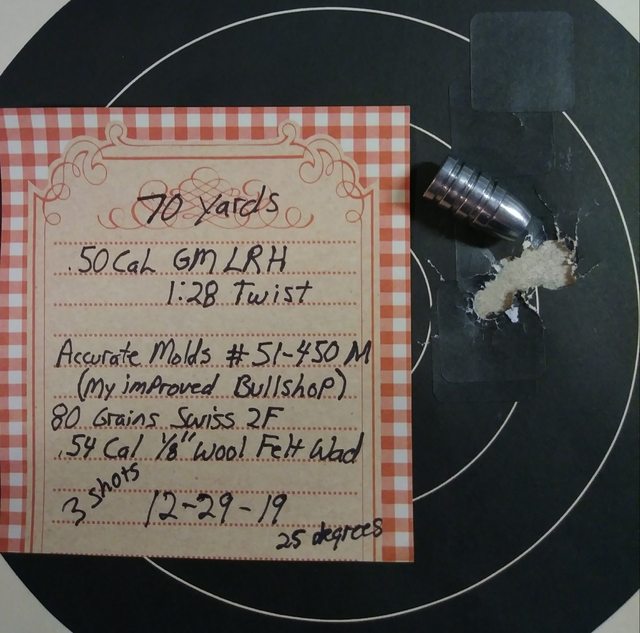

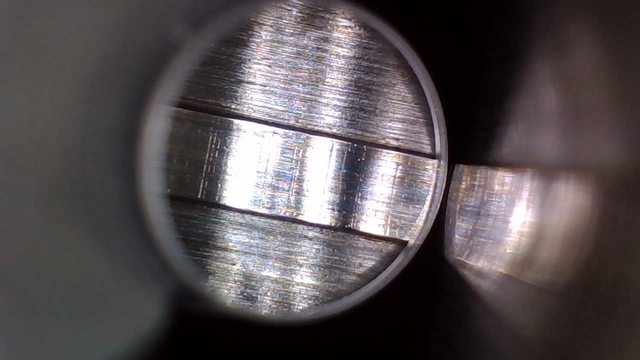

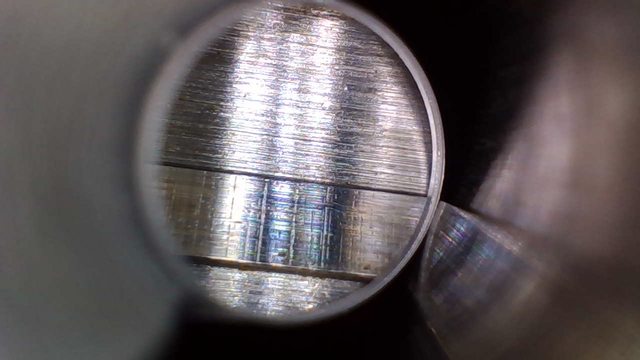

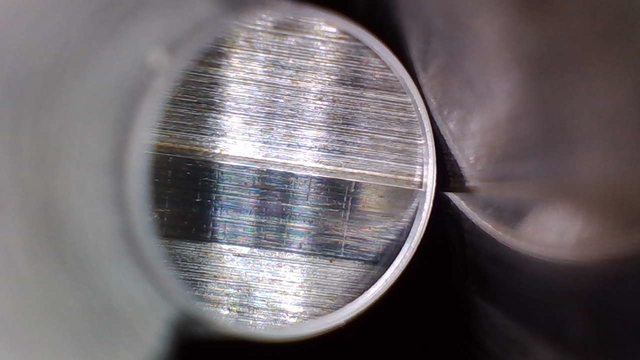

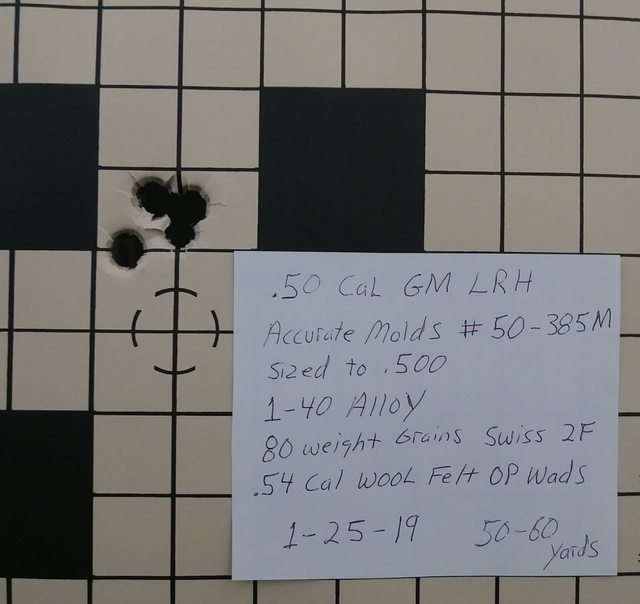

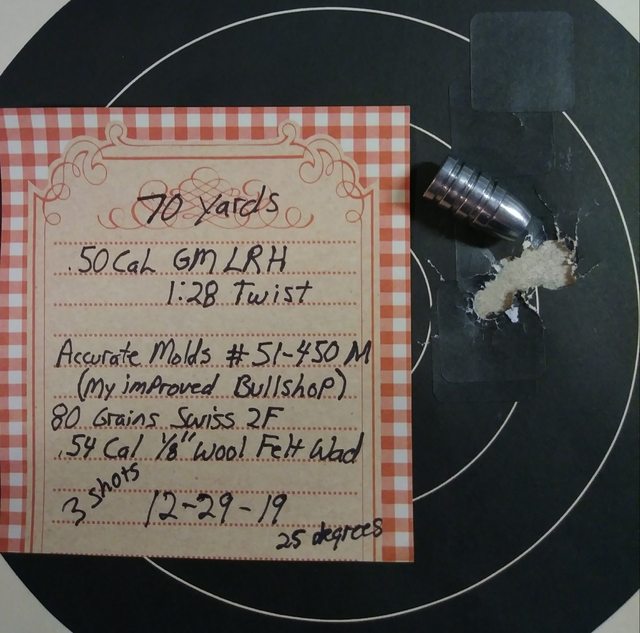

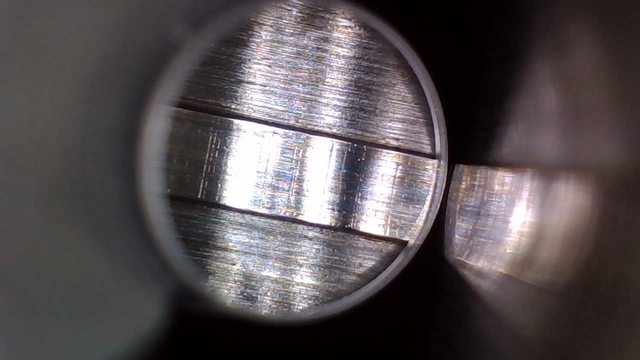

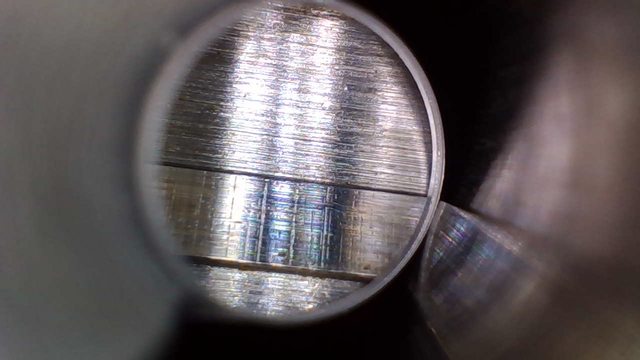

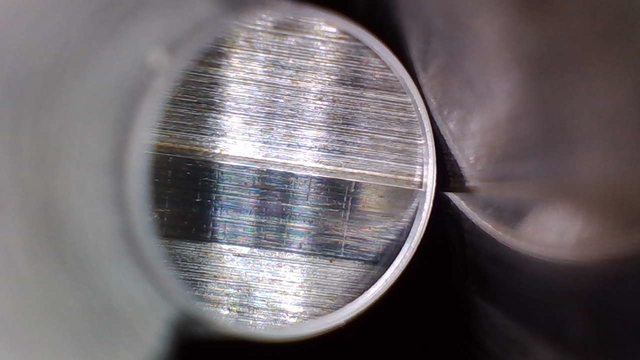

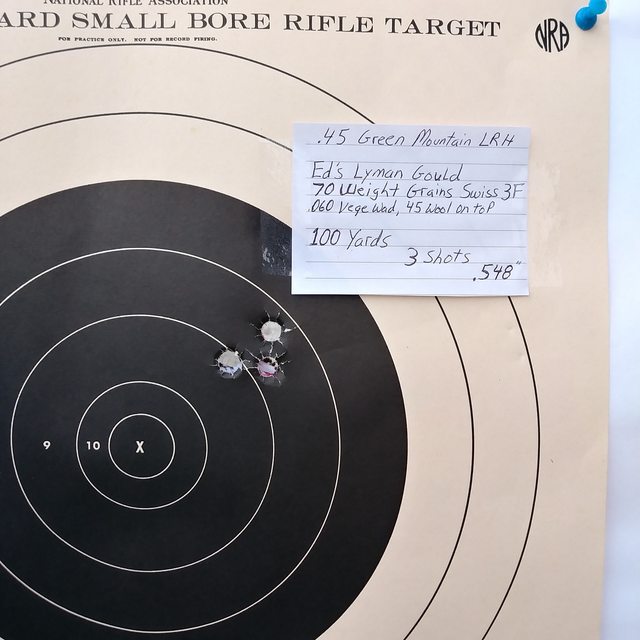

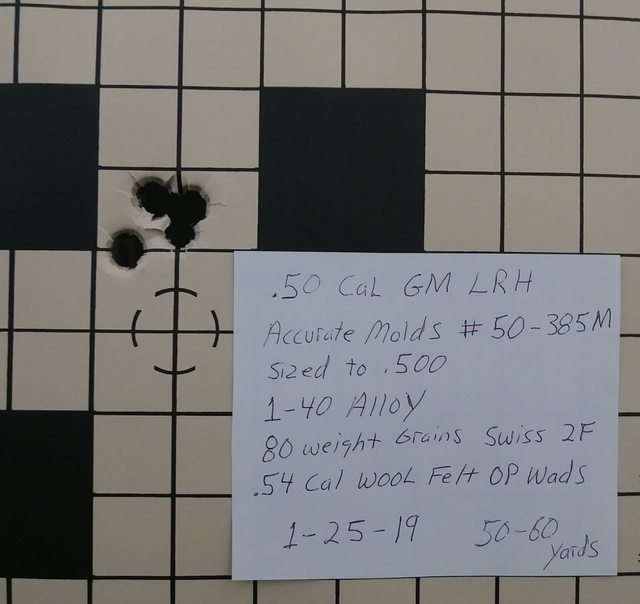

My Barrels ALL look like this

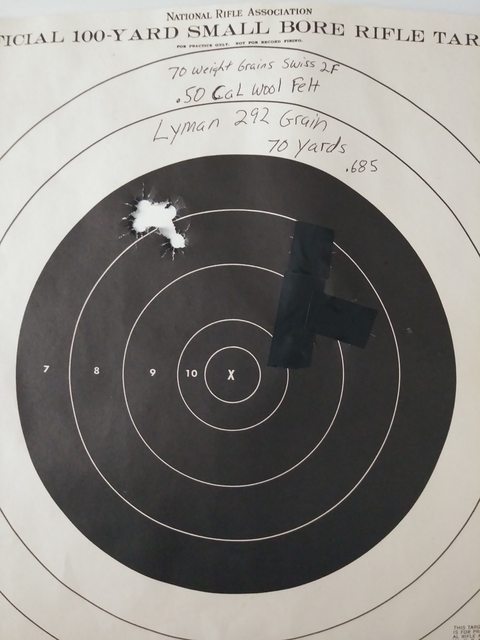

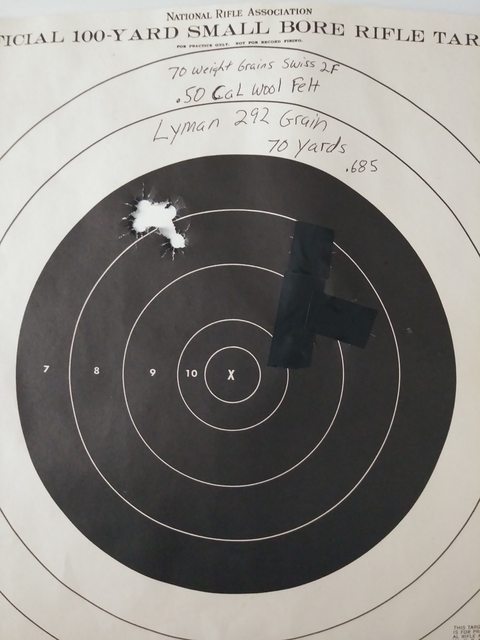

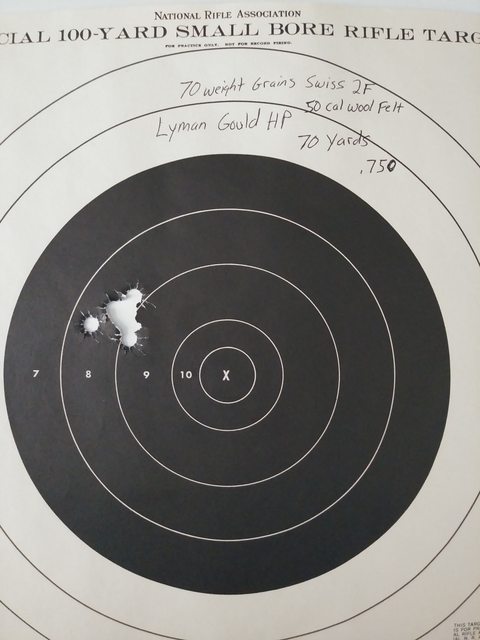

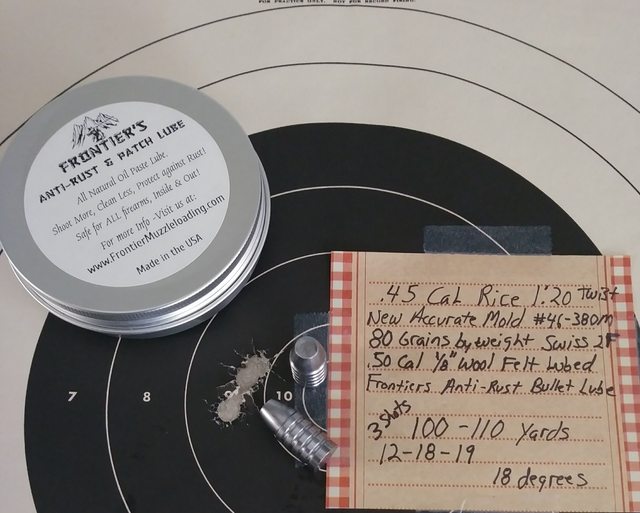

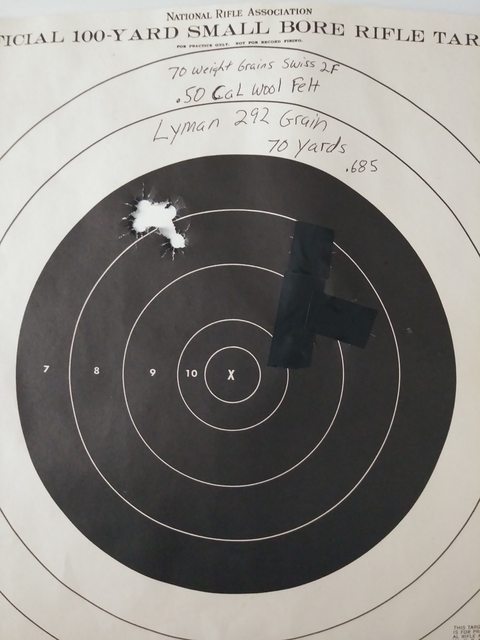

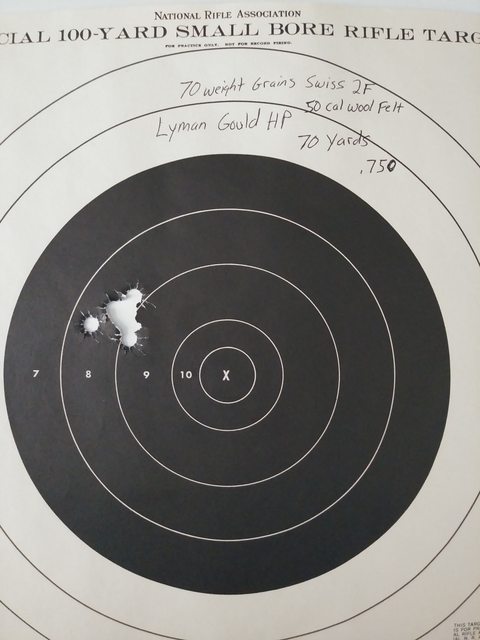

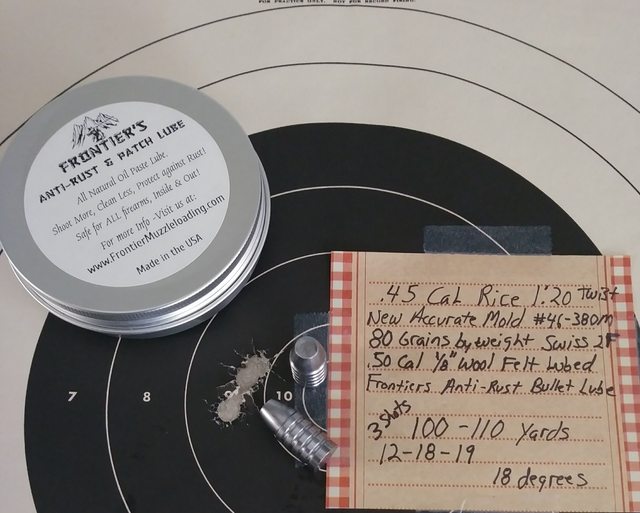

And they ALL Perform like this, or they DON’T STAY AT MY HOUSE!

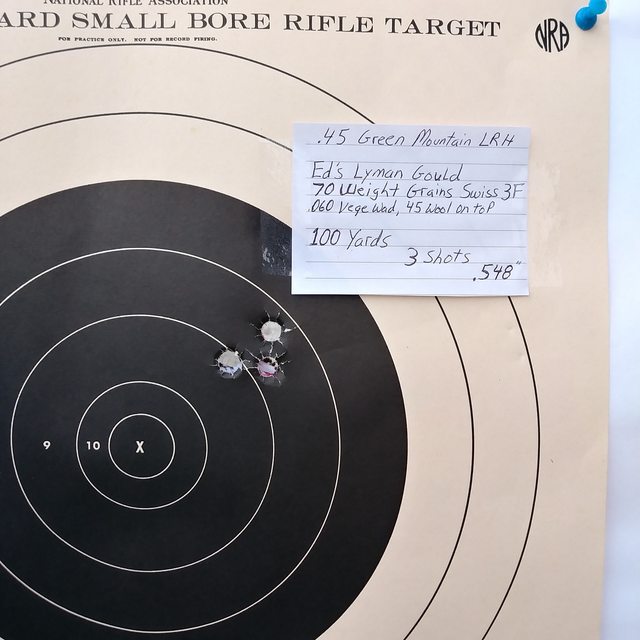

Even Patched Roundball

Very impressive. I am jealous. But, I just got the JB paste and gonna do the process again with it, 0000 wool, and patch. I'm not gonna give up because quitting is for losers!I printed up a Fresh one This Afternoon for the Shaver’s Barrel Break in Team

I started a Thread on this Quite some time ago in the “Long Range Hunting & Target Shooting” Sub forum below. This is Lee Shaver’s Process, Lee is a 2 Time World Champion, Along with NUMEROUS other Records, and Wins. I do this to EVERY Rifle i own, Before they are Ever Shot for the 1st time. You guy’s see my Results on here. Would my Rifles have shot as well as they do without doing this? I don’t know? I haven’t tried, nor do i intend to. This Process has always made good sense to me, i have followed it to the T, You guy’s see my Results on here, They Don’t lie

Lee Shaver’s Break-in Procedure

Excerpt from “Breaking In a Barrel” by Lee Shaver:

Several years ago, I developed a process for breaking-in barrels for lead bullet use

that eliminated the afternoon of shooting and cleaning with jacketed bullet. It

began because I would occasionally have to get bad leading out of a barrel for a

customer, and when you charge what a gunsmith must charge to stay in business

you don’t want to spend an afternoon scrubbing the lead out of a customer’s gun.

And I’m sure the customer would rather not pay for said services.

I polished my bore like you suggested, fixed my set trigger, and I shot a 1 3/8 group @ 50 yards. Thanks for your information friend.

What I learned was that when scrubbing lead out of a barrel, I could run a tight oily

patch through a few times and then take the patch off the jag. I would then unroll a

little 0000 steel wool and cut a piece the size of the patch. Place that over the

patch and then run it all through together. (The proper fit is when you have to

bump the rod a few times with the palm of your hand to get it started in the bore.)

When you shove that steel wool over a patch through the bore of a badly leaded

barrel, it may sound like paper tearing as the lead is ripped out of the barrel in a

pass or two. I can clean the lead out of the worst barrel in about ten or fifteen

minutes that way, and an average leaded barrel will be clean in a few strokes.

After using this technique for a while, I began to notice that the rifles that I was de-

leading that way seemed to lead less afterwards, which got me to thinking. We use

fine steel wool on the outside of old guns all the time to do some cleaning or spot

rust removal, and it does not damage the surface of the steel. It just scrubs it.

Which lead me to consider the fact that we are trying to break in a barrel by

smoothing the surface without cutting, and it seems to me that process would go

much quicker if we used something on the inside of the bore that was closer to the

hardness of the barrel instead of lead or copper. So I started trying the steel wool

and oiled patch technique on new barrels before shooting them. I use it about as

tight as I can get in the bore and wear out a steel wool pad or two in about 15

minutes, then I go and shoot the rifle.

How well does it work you might ask? On a few occasions, I have built a new rifle

and taken it to a match without ever having fired the rifle. All have performed

flawlessly in their first match and several times I won the match or set a record

with them. On one occasion, I set a new 300 yard range record with the first 13

shots out of a barrel. This method has become a service we offer to our customers

here in the shop and I have shared the technique many times with others.

So the next time you get ready to shoot that new rifle, just remember it is important

to break in a barrel properly, but if the operation you are doing to the barrel cuts –

it is not breaking it in. It may be making the barrel smoother, but to break the

barrel in you need to polish the bore by burnishing not cutting either by shooting it

or scrubbing it.

Lee Shaver

My Barrels ALL look like this

And they ALL Perform like this, or they DON’T STAY AT MY HOUSE!

Even Patched Roundball

I developed a good mink oil load for my Lyman Great Plains. 60 gn 3f Goex, .015 mink oil patch, .498 ball. I shot a 1 3/8 group @ 50 yards. I have a set of scales coming tomorrow which will allow me to tighten the group through discarding balls that weigh different than the average.Hi James,

You haven't told us what rifle you are shooting. Brand and caliber would be helpful...

Also because you are using a patch we are to assume you are shooting a round ball?

For the most part, a spit patch will work fine as long as you are shooting right away. Mink oil for longer dwell time in the barrel.

However, at some point you will want to establish a load with the mink oil and patched round ball.

At the next range secession, try to find some of your patches to see how they look.

This will be beneficial in determining patch fit and barrel condition.

Good luck!

Sam A.

Does Dyna-Tek say how many shots it takes to "fire cure"? Also, if I understand your post, after shooting you would decide if it needs anything (judged by the accuracy from the "fire curing" rounds) then possibly use something like the Lee Shaver method?Depends on the barrel. I doubt a nitride barrel would need to be "broke in" the same way as a regular barrel. My NULA (Douglas Prem XX) and Pacnor SM grade barrels were both hand lapped by the vendor. Both are as smooth as i could ever want.

Knights with the Dyna-tek coating i would just shoot first with some conicals. Sabots are probably fine too. Then decide later if it needs anything. The coating needs to be "fire cured" first according to Dyna-tek.

Standard CM and SS barrels i would scrub the snot out of before its ever fired the first time. Some of the long term storage products they use for shipping/storage can be a major pain to remove if you dont get it all out first. There is no telling how long they sat before reaching our shores or sat on a shelf after leaving Spain, Italy ect ect. MX bore polish or JBs followed up with a good CLP until you are sure the storage lube/grease is gone.

Enter your email address to join: