- Joined

- Jun 18, 2019

- Messages

- 173

- Reaction score

- 279

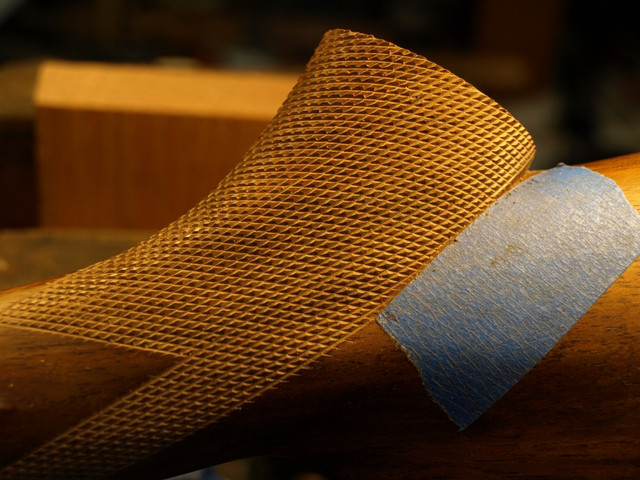

After some off-post conversation with Westbj2 I decided to make a few checkering tools to help with achieving a period look of the checkering.

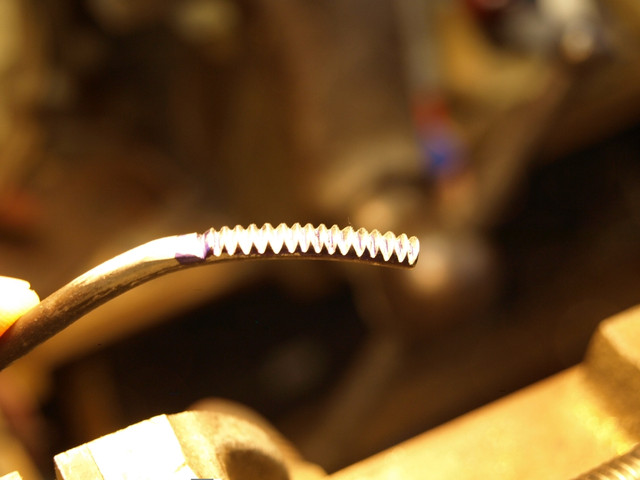

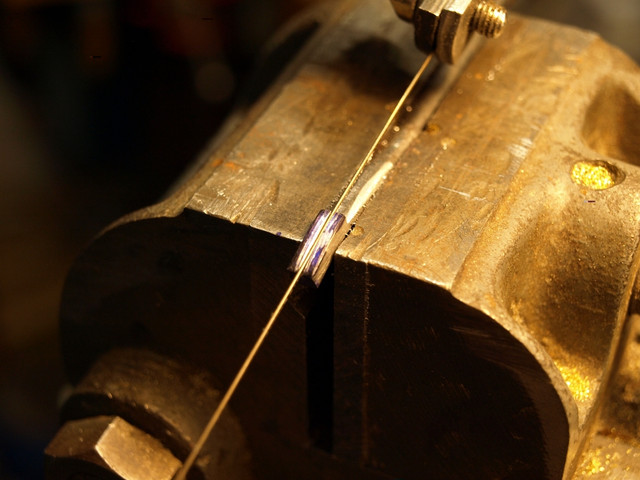

The first tool is an 80 degree double cut. I started out with a spring steel wire form a source you will never guess... times up! About 10 years ago I burned an early 20th century spring mattress on a brush-pile, and harvested several feet up different size pieces of spring wire, high carbon stuff. After the fire the wire was all nicely annealed. I forged one end to a square-ish head and bent it in a vise:

Next I shaped the head by filing, then cut a slot down the center, then cut teeth with a knife edge file:

I hardened the head by heating red hot and quenched in kerosene, a trick I learned from George Suiter - the kerosene leave very little slag to clean off. I polished the head and drew it back to a light straw.

Put a handle on it and it was ready to use.

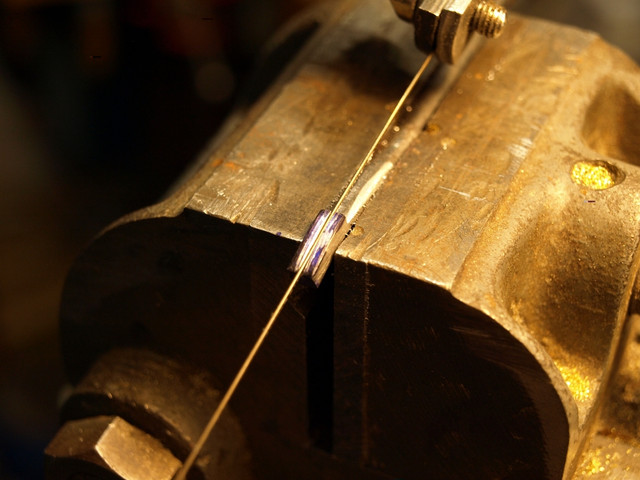

Forgot to mention - I first made an 80 degree template from a scrap of German silver to use as a guide.

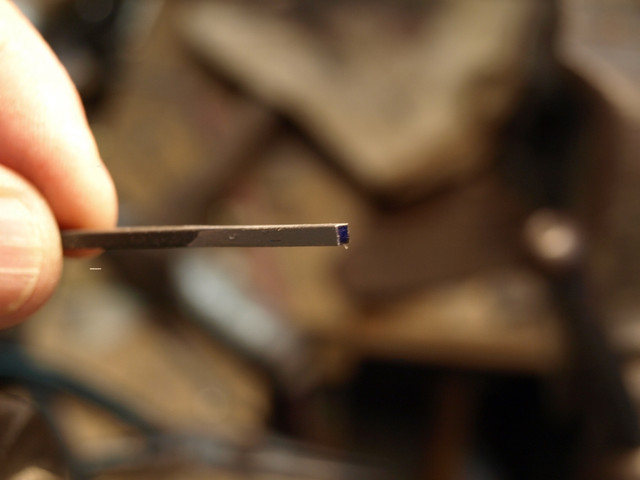

The next tool was a single cut 80 deg tool, made from some W1 tool steel I got from a friend for another project. I filed the head area to 80 deg and bent it using a vice and finger pressure. Then I cut teeth and heat treated the tool.

Last, I made a high-quality handle for the tool.

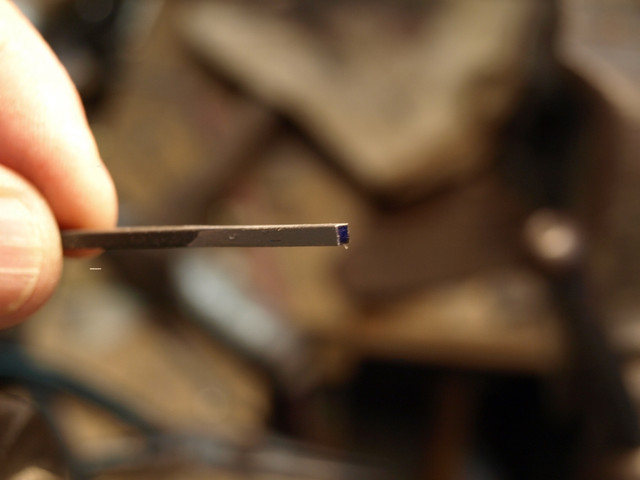

Then I got the bright idea to put a hard maple handle on the tool for the added mass, and managed to break the cutter by careless pressure in a vice when I was pounding the new handle on it!

When life gives you lemons, make lemonade! So I made a new 80 deg tool, then annealed the broken one, re-bent the shape and made a small tool for getting into hard places, and back cutting next to borders. I put the corn cob back on that one....

More to come later...

Curtis

The first tool is an 80 degree double cut. I started out with a spring steel wire form a source you will never guess... times up! About 10 years ago I burned an early 20th century spring mattress on a brush-pile, and harvested several feet up different size pieces of spring wire, high carbon stuff. After the fire the wire was all nicely annealed. I forged one end to a square-ish head and bent it in a vise:

Next I shaped the head by filing, then cut a slot down the center, then cut teeth with a knife edge file:

I hardened the head by heating red hot and quenched in kerosene, a trick I learned from George Suiter - the kerosene leave very little slag to clean off. I polished the head and drew it back to a light straw.

Put a handle on it and it was ready to use.

Forgot to mention - I first made an 80 degree template from a scrap of German silver to use as a guide.

The next tool was a single cut 80 deg tool, made from some W1 tool steel I got from a friend for another project. I filed the head area to 80 deg and bent it using a vice and finger pressure. Then I cut teeth and heat treated the tool.

Last, I made a high-quality handle for the tool.

Then I got the bright idea to put a hard maple handle on the tool for the added mass, and managed to break the cutter by careless pressure in a vice when I was pounding the new handle on it!

When life gives you lemons, make lemonade! So I made a new 80 deg tool, then annealed the broken one, re-bent the shape and made a small tool for getting into hard places, and back cutting next to borders. I put the corn cob back on that one....

More to come later...

Curtis