You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Casting Tip: Mold Temperature for PURE Lead

- Thread starter Idaholewis

- Start date

Help Support Modern Muzzleloading Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

- Joined

- Dec 2, 2018

- Messages

- 489

- Reaction score

- 431

Just made bullet lube for the first time. Bullets still cooling down in the hot bees wax, paraffin and Lyman Super Moly (been in basement for over 20 years). If I can ever get to the range again I'll let you know how they shoot. Pure Lead 456.2 grs which make a great sound when going thru target at 100 yards.

- Joined

- Sep 19, 2017

- Messages

- 1,574

- Reaction score

- 1,879

What bullet is that?View attachment 9695

Just casted these a few minutes ago, they are all within a grain +/- 1.

Thanks Idaholewis.

- Joined

- Dec 2, 2018

- Messages

- 489

- Reaction score

- 431

It's from a mold I had made from Mountain Molds for my Whitelightings. Bullet is .503 (I resize to .501) pure lead and about 456 grains in weight. They fit in both of my Whitelights great.What bullet is that?

- Joined

- May 18, 2020

- Messages

- 305

- Reaction score

- 584

I thought the collective, particularly those of us who are pedantic by nature, would find this article informative. Author states, basically, that using locking mould handles decreases weight variance of cast bullets over using "regular" handles. Apparently, the casters hand pressure can create variation in cast weight of bullets.

But, what the hell do I know?

http://www.texas-mac.com/Evaluation_of_Locking_Handles_for_Casting_Moulds.html

But, what the hell do I know?

http://www.texas-mac.com/Evaluation_of_Locking_Handles_for_Casting_Moulds.html

- Joined

- Nov 11, 2018

- Messages

- 8,354

- Reaction score

- 11,968

Thx. I had seen that article before but couldnt find it again. I am going to put those on my fav mold before my next session.I thought the collective, particularly those of us who are pedantic by nature, would find this article informative. Author states, basically, that using locking mould handles decreases weight variance of cast bullets over using "regular" handles. Apparently, the casters hand pressure can create variation in cast weight of bullets.

But, what the hell do I know?

http://www.texas-mac.com/Evaluation_of_Locking_Handles_for_Casting_Moulds.html

- Joined

- May 18, 2020

- Messages

- 305

- Reaction score

- 584

So I just ordered a set of the steel long handles. They are available in Steel and Aluminum, both regular (2 cavity handle) and long (Lee six cavity handle). The handles are a bit steep at $70, but the bigger crime is the shipping, which totals more than $15 at cowboybullets.com. I'd like to do a test comparing both handles, but I think I lack the experience to come to any meaningful conclusions.

Not sure why I ordered the damn things now, anyway. I just had surgery on both my hands, so I can't do any casting. I can only stare impotently at my molding gear, and wait...

Not sure why I ordered the damn things now, anyway. I just had surgery on both my hands, so I can't do any casting. I can only stare impotently at my molding gear, and wait...

Idaholewis

Well-Known Member

- Joined

- Jun 30, 2017

- Messages

- 7,287

- Reaction score

- 10,288

Cabin Tree handles (Same as my Lead Hardness Tester) Cabin Tree sold part of it’s Business

http://www.castingstuff.com/

Sold to this outfit

http://cowboybullets.com/

http://www.castingstuff.com/

Sold to this outfit

http://cowboybullets.com/

Idaholewis

Well-Known Member

- Joined

- Jun 30, 2017

- Messages

- 7,287

- Reaction score

- 10,288

Buffalo Arms Carries those Handles, I have looked at them MANY of times over the last few years, But have never Bought & Tried a Set of them. I don’t have any Problems Casting with Regular Handles, So didn’t see any Need/Benefit in them for me personally. I know some Guy’s really like them, They Cater Mostly to Older “Limp Wristed“ fellas like you @jcnull2305

- Joined

- May 18, 2020

- Messages

- 305

- Reaction score

- 584

Listen, Pally, at this point, I'll take all the help I can get! Locking Mould Handles equal more consistency. You, sir, are always preaching consistency - doing experiments and tests and all that.I don’t have any Problems Casting with Regular Handles, So didn’t see any Need/Benefit in them for me personally.

I'm trying the handles. You're single-handedly making skunks an endangered species. We all have our projects.

Idaholewis

Well-Known Member

- Joined

- Jun 30, 2017

- Messages

- 7,287

- Reaction score

- 10,288

So I just ordered a set of the steel long handles. They are available in Steel and Aluminum, both regular (2 cavity handle) and long (Lee six cavity handle). The handles are a bit steep at $70, but the bigger crime is the shipping, which totals more than $15 at cowboybullets.com. I'd like to do a test comparing both handles, but I think I lack the experience to come to any meaningful conclusions.

Not sure why I ordered the damn things now, anyway. I just had surgery on both my hands, so I can't do any casting. I can only stare impotently at my molding gear, and wait...

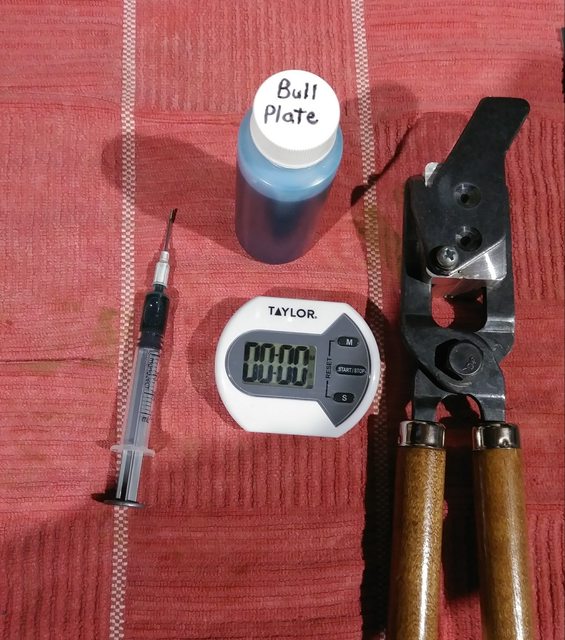

View attachment 9907

Joking aside, I think you will like the Handles

I can see how they would be nice, You set them, They close and hold the Mold the EXACT same each time.

I can see how they would be nice, You set them, They close and hold the Mold the EXACT same each time.Idaholewis

Well-Known Member

- Joined

- Jun 30, 2017

- Messages

- 7,287

- Reaction score

- 10,288

Listen, Pally, at this point, I'll take all the help I can get! Locking Mould Handles equal more consistency. You, sir, are always preaching consistency - doing experiments and tests and all that.

I'm trying the handles. You're single-handedly making skunks an endangered species. We all have our projects.

View attachment 9909View attachment 9908

- Joined

- May 18, 2020

- Messages

- 305

- Reaction score

- 584

@Idaholewis: If you'd like, Since I'm out of commission, I can send them to you when they get here to conduct some tests to find if they really make a difference. Your abilities and experience are without question, here. You can report back to the gang.

I would be absolutely gutted if you find no or little difference after spending the $$. But it's a sacrifice I'd be willing to make in the name of science!!

I would be absolutely gutted if you find no or little difference after spending the $$. But it's a sacrifice I'd be willing to make in the name of science!!

Idaholewis

Well-Known Member

- Joined

- Jun 30, 2017

- Messages

- 7,287

- Reaction score

- 10,288

@Idaholewis: If you'd like, Since I'm out of commission, I can send them to you when they get here to conduct some tests to find if they really make a difference. Your abilities and experience are without question, here. You can report back to the gang.

I would be absolutely gutted if you find no or little difference after spending the $$. But it's a sacrifice I'd be willing to make in the name of science!!

I would enjoy Testing them

Did you purchase them from Buffalo Arms, or elsewhere? I can test them with the EXACT same .54 Cal Mold that you Bought, If You pay for the Lead, and Small Flat Rate Shipping Box, I will Cast you up a Good Bunch of these #54-510s from my Mold and Send them to ya

Did you purchase them from Buffalo Arms, or elsewhere? I can test them with the EXACT same .54 Cal Mold that you Bought, If You pay for the Lead, and Small Flat Rate Shipping Box, I will Cast you up a Good Bunch of these #54-510s from my Mold and Send them to ya- Joined

- May 18, 2020

- Messages

- 305

- Reaction score

- 584

Got the handle from Desperado Cowboy Bullets (here: MLDHNDL-Mould Handle). I also just received my 54-510M mold from Accurate - Flat base specified (no bevel).I would enjoy Testing themDid you purchase them from Buffalo Arms, or elsewhere? I can test them with the EXACT same .54 Cal Mold that you Bought, If You pay for the Lead, and Small Flat Rate Shipping Box, I will Cast you up a Good Bunch of these #54-510s from my Mold and Send them to ya

insofar as your offer for 'em bullets:

PM me with details...

- Joined

- May 18, 2020

- Messages

- 305

- Reaction score

- 584

Alright, Kids. ST Machining Mold handles are here!!!

IdahoLewis and I have developed a plan for another IdahoLewis Test as outlined above. I have graciously lent my expertise to this exercise. And, to be clear, by "graciously lent my expertise to this exercise," I mean to say that I bought the damn things and put them in a box - Lewis will do all the work.

I'm thinking another YouTube Video and casting thread party!!! I'll buy the sodas and Pie!!!!!

IdahoLewis and I have developed a plan for another IdahoLewis Test as outlined above. I have graciously lent my expertise to this exercise. And, to be clear, by "graciously lent my expertise to this exercise," I mean to say that I bought the damn things and put them in a box - Lewis will do all the work.

I'm thinking another YouTube Video and casting thread party!!! I'll buy the sodas and Pie!!!!!

- Joined

- Nov 11, 2018

- Messages

- 8,354

- Reaction score

- 11,968

Mmmmm pie

- Joined

- Nov 11, 2018

- Messages

- 8,354

- Reaction score

- 11,968

OTE="jcnull2305, post: 313283, member: 23546"]

So I just ordered a set of the steel long handles. They are available in Steel and Aluminum, both regular (2 cavity handle) and long (Lee six cavity handle

[/QUOTE]

Do they say what molds those regular handles fit? Lee or Lyman? If they fit a Lyman 1 cavity mold im going to buy one.

So I just ordered a set of the steel long handles. They are available in Steel and Aluminum, both regular (2 cavity handle) and long (Lee six cavity handle

[/QUOTE]

Do they say what molds those regular handles fit? Lee or Lyman? If they fit a Lyman 1 cavity mold im going to buy one.

- Joined

- Aug 15, 2014

- Messages

- 1,052

- Reaction score

- 484

This is a MAJOR part of Casting HIGH Quality PURE Lead Bullets, in Fact it’s The most important Part i can Think of? Temperature of the PURE Lead is Very important as Well, These 2 Go Hand n Hand. I get my BEST Results with PURE Lead at 775-800 Degrees

With a Clean, Oil Free Mold. You have to Get the Mold HOT, and i mean REALLY HOT! (Remember, Aluminum molds heat up REALLY fast, Steel Molds take CONSIDERABLY longer to Heat up, Over Twice as long as Aluminum)

How i do this is quite Simple, I hold the Bottom of my Mold in the Molten Lead. My Goal is to Slightly Over Heat the Mold, When i make my 1st Cast the Sprue Puddle Can Take up to 1 minute to Solidify (Depending on Bullet Cavity Size), As quick as i see the Puddle FULLY Solidify (if it’s a Large Bullet, you will notice a Hole “sinking in” the Center of the Lead) Count a FULL 45 Seconds to 1 Minute here BEFORE Opening the Mold to Dump the Bullet out. If the Bullet has not Solidified it will make a Hell of MESS in your Mold, You end up losing what you Gained by having to Clean the Stuck Lead from the Mold Halves (If this Happens, use a Clean WOOD STICK like a Popsicle, or Paint Stick to Scrape the Lead out, Anything else Can/will Scratch Your Mold) Trust me when i Say To make Sure the Bullet has Fully Solidified before opening the Mold! Get yourself a Kitchen Timer, They are Cheap, and an invaluable little tool to the Serious Caster.

Using the Method i describe above (Dipping the Bottom of the Mold in the Molten Lead) Here are times i use, I am gonna list times i use for IRON/STEEL Molds, as i rarely Cast with Aluminum Molds (I DESPISE Aluminum Bullet Molds) I don’t Guess these times, I use a Kitchen Timer and get them Exact.

My Iron/Steel Lyman Molds Take about 4 Minutes to Slightly Over Heat

my Iron/Steel Accurate Molds take About 7-8 Minutes to Slightly Over Heat, CONSIDERABLY Longer Than my Lyman Molds, as they are MUCH Bigger and Heavier than a Lyman Mold.

Now that you have Slightly Over Heated your Mold, Swing the Sprue Plate WIDE OPEN and Fill the Cavity (As stated above, DO NOT Try and Dump this 1st Bullet out to Fast, give it a FULL 45 Seconds to 1 Minute AFTER You See the Sprue Puddle Finally Solidify) As quick as you are able to Safely Dump this 1st Bullet out, IMMEDIATELY Fill the Cavity again, This time it will Take Considerably Less time to Solidify, When you are Sure it has Solidified, Dump this Bullet as well, and IMMEDIATELY Fill the Cavity again. Do this for about 5-6 Cycles/Bullets, Now Swing the Sprue Plate Closed and Start Casting For Keeps

I over heat as well and when I'm casting my 600 grainers I tap lightly on the mold with my wooden sprue mallet I always have the entire mold filled also with these kind of weights you have to cast hotter than usual to fill the molds out properly imo

Similar threads

- Replies

- 5

- Views

- 713

E PIE!!!!!

E PIE!!!!!