- Joined

- Dec 30, 2020

- Messages

- 356

- Reaction score

- 535

You can become a Supporting Member which comes with a decal or just click here to donate.

Maybe take a small bit of steel, solder it into the slot, file it down until it just stands proud of the head of the screw. Like a very small wing nut.If I dont find one soon I may just modify the existing knob. Maybe file in some notches around the perimeter for grip. Or I could grind a flat spot on top and drill and tap for a larger diameter knob. Anyone have any other ideas?

That is a great idea. I will probably do this. Thanks for the ideaMaybe take a small bit of steel, solder it into the slot, file it down until it just stands proud of the head of the screw. Like a very small wing nut.

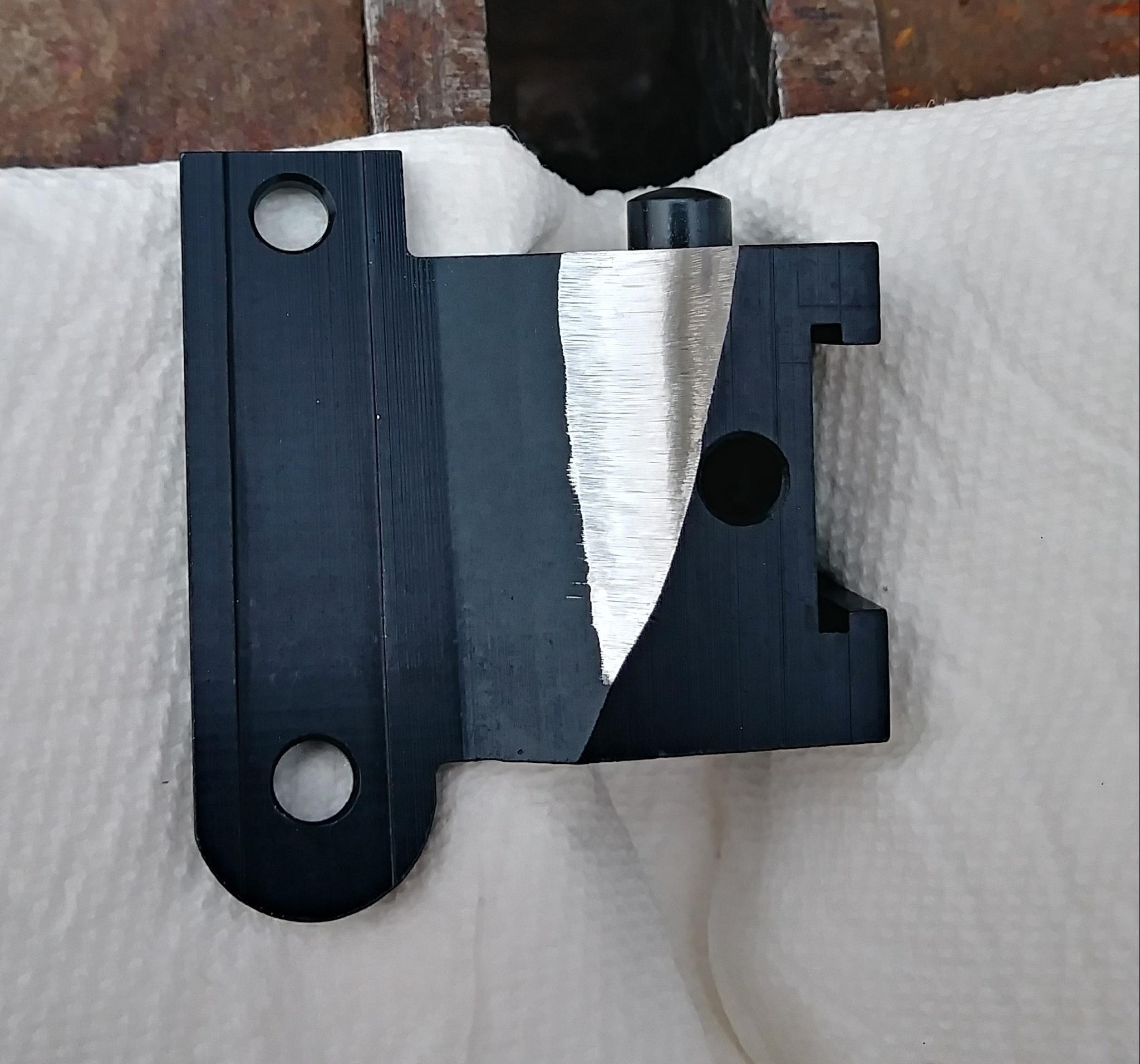

I filled down the high shoulder. I took that pic to send to a buddy and realized shortly after it was not square. I fixed that, it’s now square (as shone in this pickture). Still need to shim it though to get it perpendicular to the barrel channel. Didn’t really thing about it until you attached those pictures. I’ll get some shim stock from work and put it under front foot (beauty of working in heavy industry, always tools and such to borrow)

Yeah, that’s kinda what I was thinking of doingI think the "bit of steel" idea is a good idea, but for your purposes soldering it is overkill. I'd get it shaped to what you want through trial and error, then clean it up and JB Weld it in place.

I only mention solder because I picked up a tube of solder-it (brand name) and I can now solder with my heat gun and a bbq lighter… much stronger than jb weld.I think the "bit of steel" idea is a good idea, but for your purposes soldering it is overkill. I'd get it shaped to what you want through trial and error, then clean it up and JB Weld it in place.

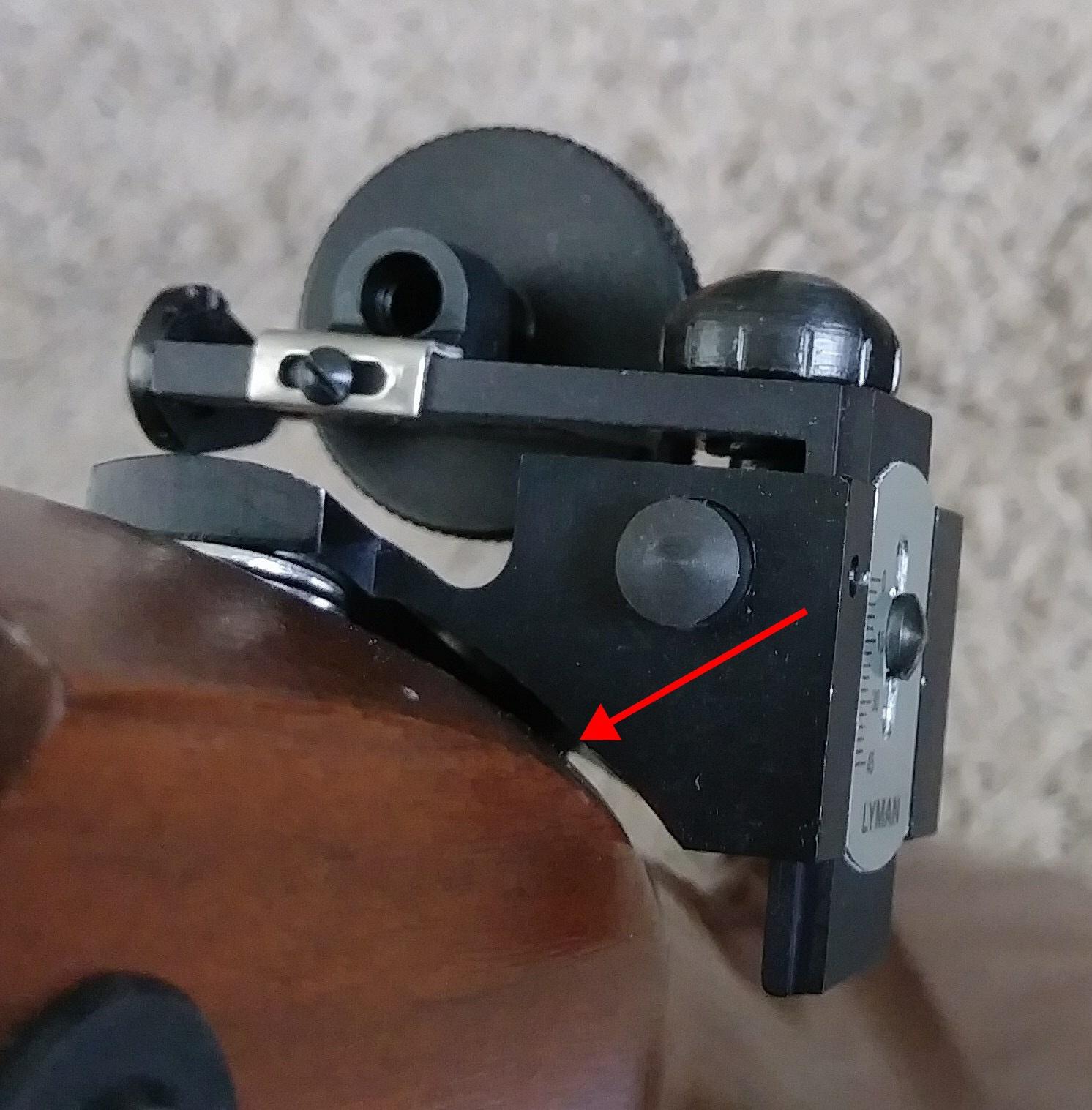

Actually that’s for the Williams foolproof sight. I do have one of those sights as well but you can still find that part for sale onlineIs this what you are looking for?

. send me a pm and we can work out the details.

. send me a pm and we can work out the details.Yep, watched a YouTube video, ordered it and I’ve been really happy with the results.Is this it? Never heard of it before. I learn something new every day...

View attachment 16085

Enter your email address to join: