- Joined

- Dec 29, 2007

- Messages

- 4,943

- Reaction score

- 3,089

In the 'New to Muzzleloading' forum, a writer posted he was wanting to purchase the special Blackhorn QRBP for his rifle, but they are currently out of stock. What follows is one alternative done in 2012, that utilized a drill press, a standard QRBP, and a two by four chunk.

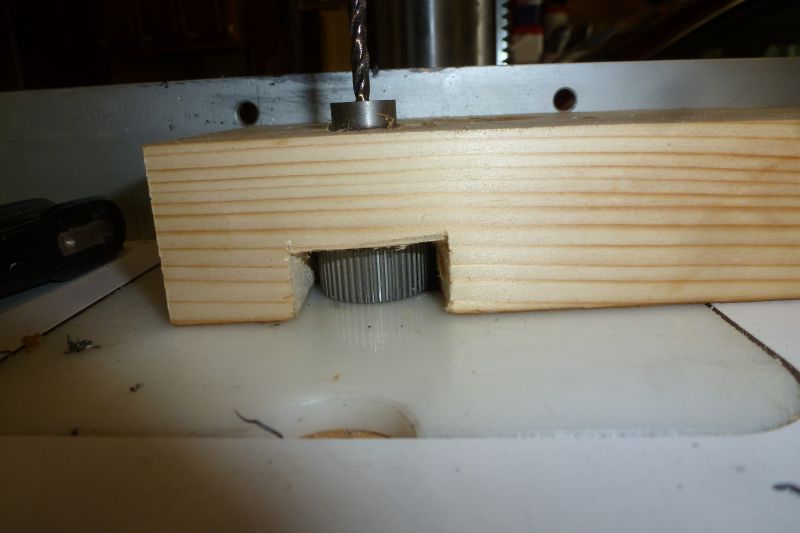

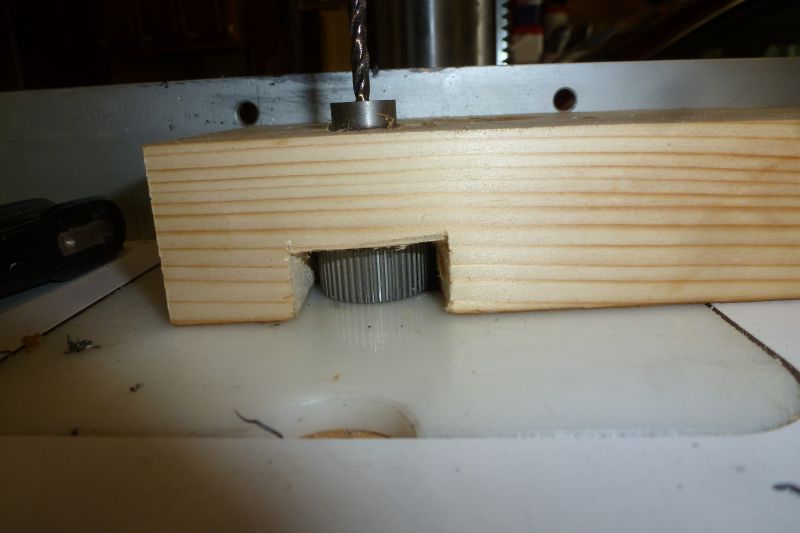

Started with a 1 1/8" drill, and made the hole deep enough to hold the head of the QRBP. Then switched to a 5/8" drill and drilled all the way through the 2 X 4.

A 5/32" drill was chucked, the QRBP placed in the jig, lubricated, and the flame channel was enlarged by drilling the full length of the plug.

The clamp was removed holding the 2by to the drill press. The edge of the 1 1/8" hole was chiseled away.

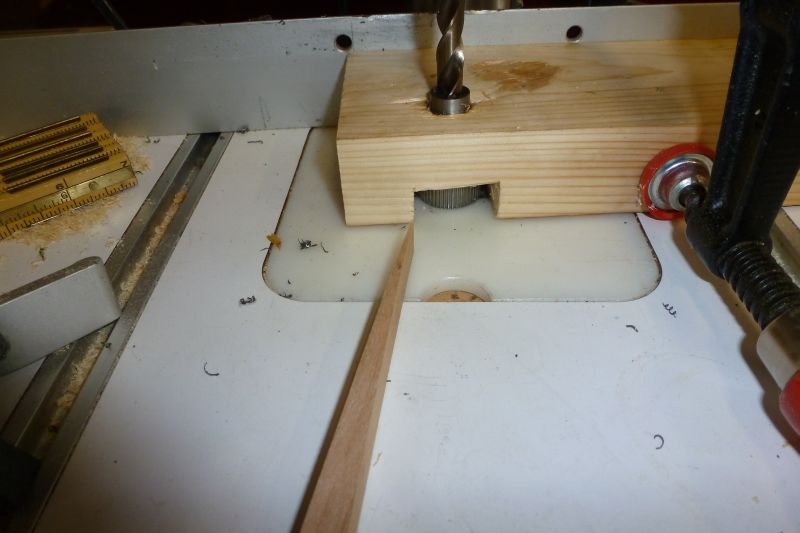

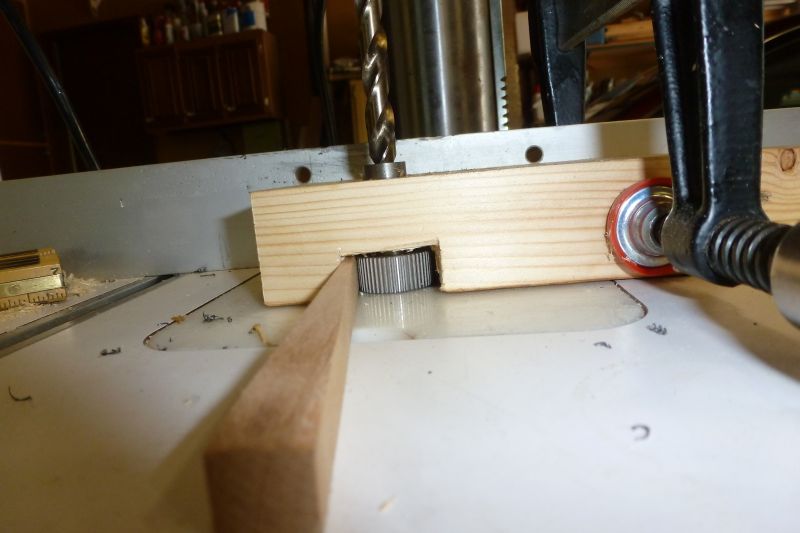

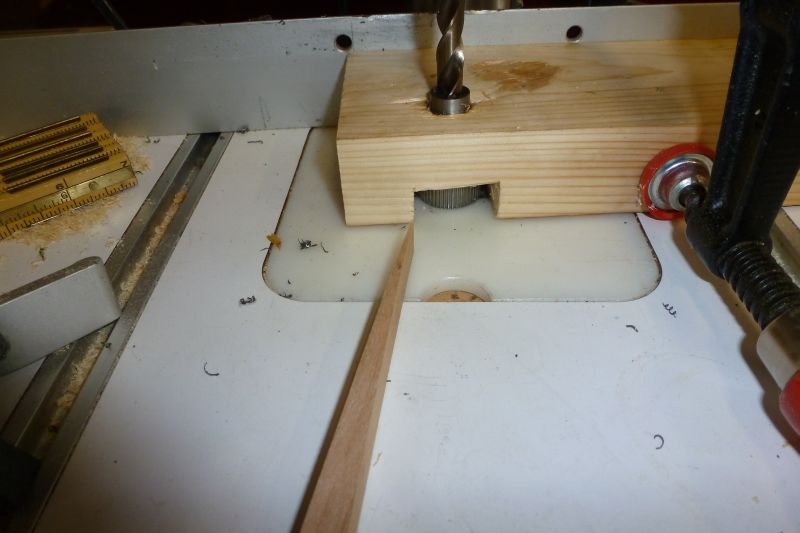

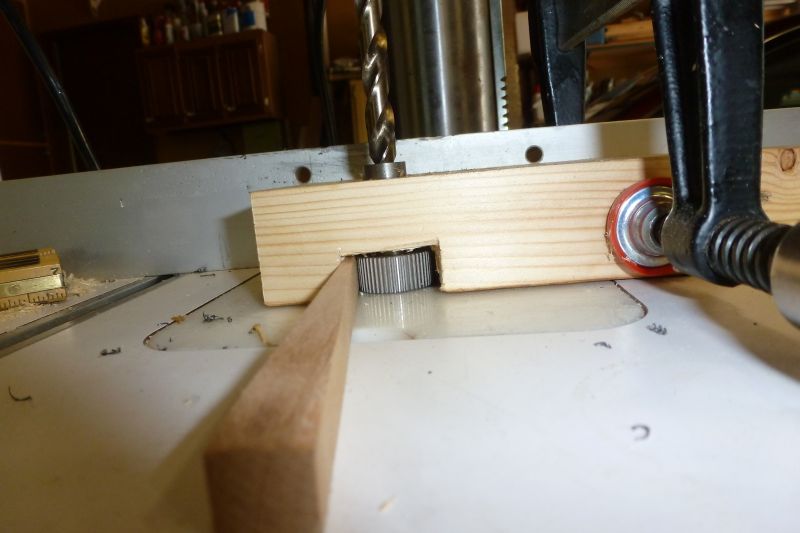

The QRBP was installed into the 2by and the shebang was placed on the drill press table with the powder end of the plug up. The 5/32" drill was used to center the plug before the 'jig' was clamped to the fence.

A 3/8" drill was chucked and lowered to the QRBP. The depth stop was set to 1/4". Wedges were used to stop the plug from spinning. This turned out to be a struggle; the plug kept wanting to spin.

After the 3/8" hole was made 1/4" deep the drill was replaced with a # 4 1/2 center drill. This drill cuts so the slope of the cut is 82 degrees which is what the slope of the head of standard vent liner is.

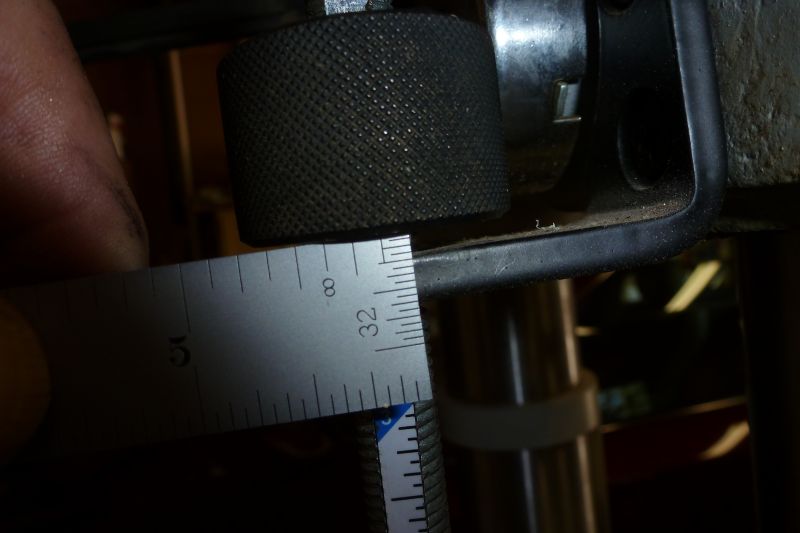

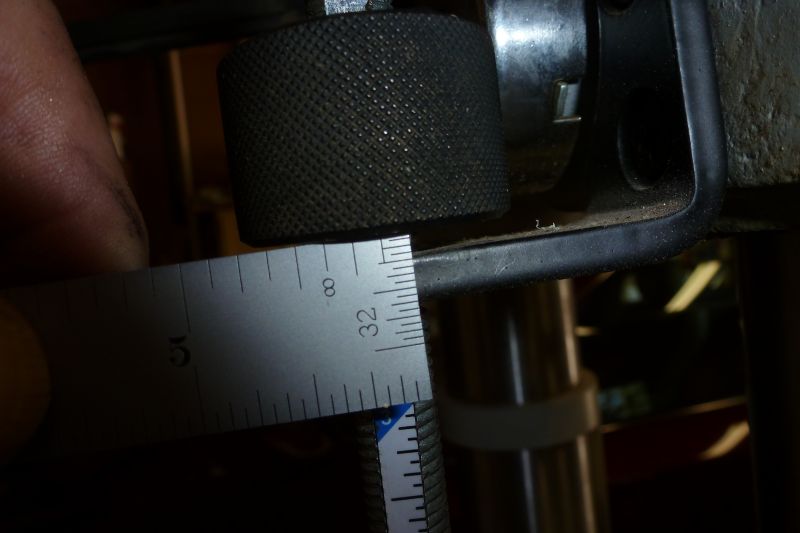

The center drill was lowered into the plug, and the depth stop was set at 1/8" cut.

Then the plug was ready to tap the threads for a vent liner. The belts were removed from the motor, and a 10-32 tap was chucked and about 8 revolutions of thread were cut.

The plug was finished and tested with a couple of vent liner.

The use of wedges to keep the plug from spinning wasn't so very good. Perhaps a larger mortise so a wrench could be used?

This plug very well may be better than the factory made for Blackhorn QRBP. Other QRBP made the same, have never failed to ignite BH209, ever. This plug ignites BH in sub-zero weather. It has a flash hole that won't wear out. When flash hole in the vent liner erodes, it is readily replaced. The flame channel of the factory Blackhorn plug is short and narrow. The flame channel of this plug, has more volume than the purchased plugs; it is longer and is a larger diameter. This added volume reduces the pressure on the primer, and helps keep the primer from leaking. The added volume will allow more shots at the range before the channel gets choked.

Here is another thread showing one way to make vent liners

Started with a 1 1/8" drill, and made the hole deep enough to hold the head of the QRBP. Then switched to a 5/8" drill and drilled all the way through the 2 X 4.

A 5/32" drill was chucked, the QRBP placed in the jig, lubricated, and the flame channel was enlarged by drilling the full length of the plug.

The clamp was removed holding the 2by to the drill press. The edge of the 1 1/8" hole was chiseled away.

The QRBP was installed into the 2by and the shebang was placed on the drill press table with the powder end of the plug up. The 5/32" drill was used to center the plug before the 'jig' was clamped to the fence.

A 3/8" drill was chucked and lowered to the QRBP. The depth stop was set to 1/4". Wedges were used to stop the plug from spinning. This turned out to be a struggle; the plug kept wanting to spin.

After the 3/8" hole was made 1/4" deep the drill was replaced with a # 4 1/2 center drill. This drill cuts so the slope of the cut is 82 degrees which is what the slope of the head of standard vent liner is.

The center drill was lowered into the plug, and the depth stop was set at 1/8" cut.

Then the plug was ready to tap the threads for a vent liner. The belts were removed from the motor, and a 10-32 tap was chucked and about 8 revolutions of thread were cut.

The plug was finished and tested with a couple of vent liner.

The use of wedges to keep the plug from spinning wasn't so very good. Perhaps a larger mortise so a wrench could be used?

This plug very well may be better than the factory made for Blackhorn QRBP. Other QRBP made the same, have never failed to ignite BH209, ever. This plug ignites BH in sub-zero weather. It has a flash hole that won't wear out. When flash hole in the vent liner erodes, it is readily replaced. The flame channel of the factory Blackhorn plug is short and narrow. The flame channel of this plug, has more volume than the purchased plugs; it is longer and is a larger diameter. This added volume reduces the pressure on the primer, and helps keep the primer from leaking. The added volume will allow more shots at the range before the channel gets choked.

Here is another thread showing one way to make vent liners