Idaholewis

Well-Known Member

- Joined

- Jun 30, 2017

- Messages

- 7,287

- Reaction score

- 10,288

I know i have spoke of all of these things through out different Threads But never sat down and put it all together in 1 thread, This is to try and help you achieve the most out of your rifle, and what i feel makes the biggest difference in Accuracy With Grease Groove bullets.

No. 1, Is Your Rifle itself, Make sure you have your Rifle as clean as you can possibly get it, Take the time to clean your Barrel down to Bare Steel, I do NOT believe in the “Seasoning” your bore method with Bore Butter, or any other type of Stuff, Clean your Barrel down to Bare Steel, Make sure there is no lead or Plastic in your bore, Copper Chore boy wrapped tightly around an old Wore Bore Brush works very well, make DARN SURE it is the pure Copper stuff! Refer to my video on Cleaning in the Sticky section Above.

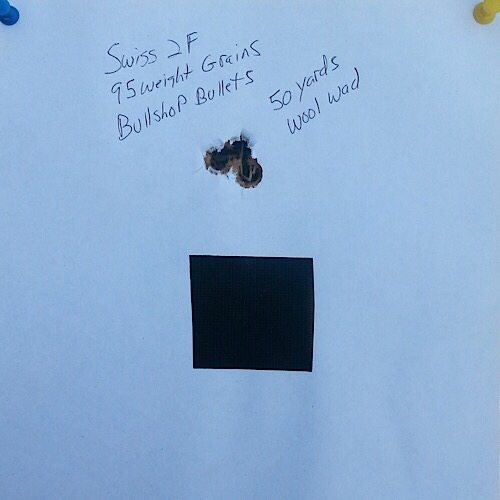

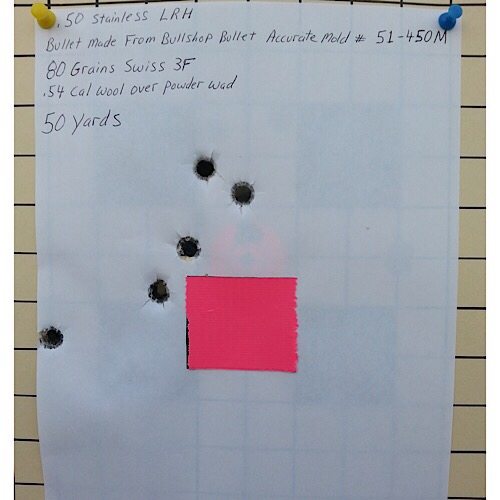

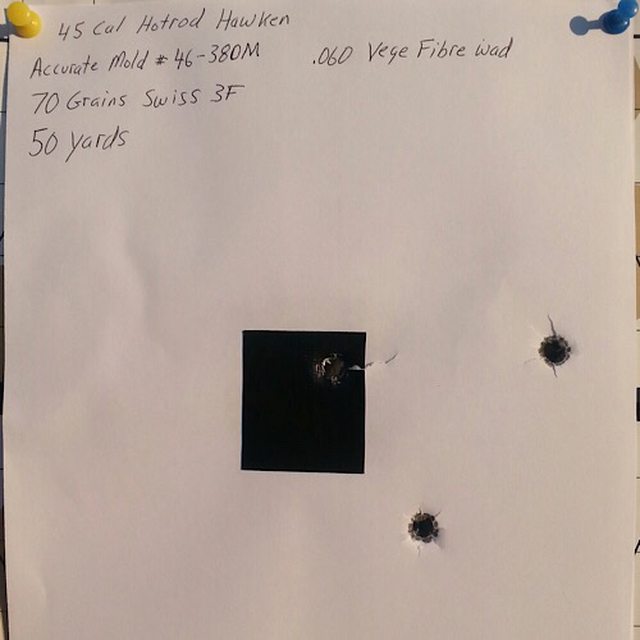

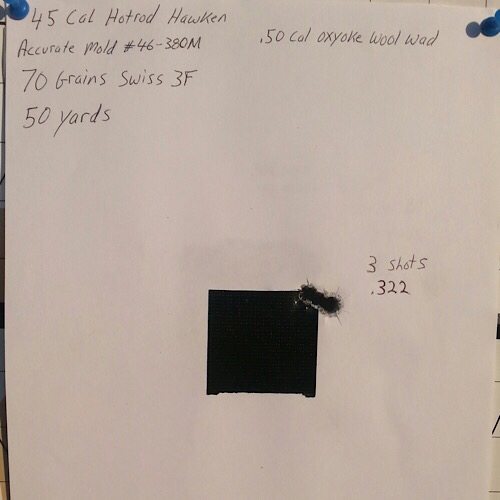

No. 2, Is your Powder Charge, I shoot Swiss 2 and 3F powder Exclusively, I prefer to Weigh my Powder Charges By weight on a Dependable Powder Scale, I have 2 really nice Volume measures but i NEVER use them to weigh my Charges, The ONLY time i ever use them is to Find out What Volume is Weighing in Weight Grains? (This is VERY important, NEVER guess this!! Some powders Will Vary substantially in Weight vs Volume) A Volume measurer was designed to get you “Close enough” for field use, That is NOT close enough for me, I want my Powder charges to be as identical to eachother as i can possibly get them!! Whatever powder you choose, Take the time to make each Charge as identical as you possibly can to eachother, The Most Accurate way to do this is on a Beam Type Powder Scale. I get my powder charges to a 10th of a Grain of eachother. Does this really matter? I absolutely believe it does! Would you trust your Centerfire Rifle Cartridges to “Close Enough”? I sure WOULDN'T! I treat my Muzzleloaders the EXACT same way as i do my Precision Centerfire Rifles. I have Handloaded my own Custom ammo since i was 15 years old, I have setup Rifles, and Taylored handloads for MANY MANY of them, I have shot out to 800 Yards VERY SUCCESSFULLY, I could easily Hit Gallon Jugs of Water at 800 Yards With my 7Mag And Handloads. Again, i treat my Muzzleloaders the Exact same as i do my Centerfire rifles.

No. 3, Is the Over Powder Wad, I want to Create a Solid, Repeatable Gas Seal behind my bullets. I have tested Several different Over Powder wad Materials, and Thicknesses over the last few years, Cork, Vegetable Fibre, Poly, And Wool, My ABSOLUTE Favorite Material is 1/8” thick Wool Felt, it has been the Clear winner for me with every type of Bullet (Except a Minie Ball, You don’t want to use a Wad of any kind with a Hollow Base Minie)

I prefer my 1/8” Wool felt Wads to be oversize, For a .45 Cal Rifle i use .50 Cal Wool Wads, for a .50 Cal Rifle i use .54 Cal Wool Wads, and For my .54 Cal Rifles i use .58 Cal Wool Wads. You have 2 options here, You can Buy Them, The ones i Buy are Oxyoke Brand and they Come in packages of 100, You could also Buy Bulk Wool Felt Material and Punch out Your Own Wads, Durofelt online is a good place to get Wool felt in Bulk, Make sure and get the 1/8” Thick stuff, I believe that to be important.

No. 4, The next thing is Your bullets. We want our Bullets PERFECT!!! If you are a bullet Caster take the time to weigh EVERY SINGLE bullet on a dependable Scale, When you have Casted with a Particular Mold and Alloy or pure lead you will know what to expect for Bullet Weight from that Mold. Lets say your mold Throws a Bullet weight of 400 Grains with pure lead, Weigh each and every bullet after your casting session and ONLY keep the bullets that Hit your weight of 400 Grains (Remember Different Alloys will Change the Bullet weight, Along with Casting technique) I shoot for Plus or Minus 1 Grain but usually get better than that when the Mold is up to temp, and running Right. So with a Mold that is Throwing a 400 Grain Bullet of Pure Lead i will keep bullets that weigh 399.5 to 400.5, If a bullet weighs 399.4 or 400.6 it goes back in the Lead pot, Be PICKY here! As a Caster you can do this! The other thing to look for, (I learned from Lee Shaver’s) is your Bullet bases (it is the base of your bullet that steers it, NOT the Nose) Make sure your bullet Bases are “Sharp” at the Edges and Completely filled out, Meaning Completely Flat across the Mold. A common thing i see is slightly Rounded Base edges, They might all weigh the Same, But the edges are not sharp, THROW THEM BACK and re Cast until you are getting FULL “Sharp” filled out Bullet bases. Keep playing with Casting techniques until you get this Down!

If you do not Cast your own bullets and are forced to Buy them you are limited here, But stil Do the same thing with them, Weigh EVERY single bullet and Sort them. I have seen Store bought (especially casted) bullets Vary LARGELY in weight, Nothing you can do about that besides Sort Through them.

No. 5, With a pile of PERFECT Bullets the next Step is Lube, I have found Lube to be EXTREMELY important! Lube can Make, or Break a Good Bullet!! I have shot Groups that were HORRIBLE, Pie plate size and Worse, And Just by Switching Bullet Lube i have had that EXACT same bullet/load Combo Shoot a true 1” or better Group, Lube is VERY IMPORTANT! I personally make my own Bullet lube of Bear Grease (rendered bear lard) Lanolin, And Beeswax. I understand that this is Not something everyone can do, The only commercial available Lube i have tried and had REALLY good luck with is Bullshop’s NASA lube, That stuff is REALLY GOOD and i highly recommended it! You can purchase this Lube From Bullshop Bullets. Your lubing technique doesn’t matter (Pan Lube, Or By hand) just fill the Grooves evenly, When you push the Bullet down the Bore wipe off any Excess Lube that was “Cut” From the Crown of your Bore.

Once you put the Above together, Sit down at a good SOLID Bench on Sand Bags, Or Something Similar, Settle the Rifle in ROCK SOLID, make sure the Rifle Can naturally Slide When it Recoils (AVOID Lead Sled type Rests!) Once you are SOLID on a Bench, Shoot your Group.

I have had people tell me that they just can’t seem to get a Good consistent Group no matter what Bullet/powder/Wad Combo they try? One of the first things i ask is What type of Rest/Bench were They were shooting from? Was it Solid? The reason i ask this is simple, The answers i have gotten NEVER CEASE to Amaze me, Most of them were shooting off hand :lol: :lol: :lol: Here’s your SIGN Buddy!! Now what good do you think that did Besides Waste powder and Lead? You accomplished nothing!! When you are working on a Load for a Rifle, and trying to get the ABSOLUTE most out of that Gun, You need to be Shooting from a SOLID REST!! AFTER You get the Rifle/Load figured out and are Shooting Tip Top, Then by ALL means Practice Away Off Hand, etc. But for God Sake when you are trying to Develop a Load for a Rifle GET ON A SOLID BENCH! DON’T expect to Stand off hand and Drive Nails, Ever heard of human error?

Hopefully this is helpful to Folks, You have nothing to lose by trying the above? NOTHING! But possibly a WHOLE LOT to Gain! Good Luck! Aim Small, Miss Small :yeah:

No. 1, Is Your Rifle itself, Make sure you have your Rifle as clean as you can possibly get it, Take the time to clean your Barrel down to Bare Steel, I do NOT believe in the “Seasoning” your bore method with Bore Butter, or any other type of Stuff, Clean your Barrel down to Bare Steel, Make sure there is no lead or Plastic in your bore, Copper Chore boy wrapped tightly around an old Wore Bore Brush works very well, make DARN SURE it is the pure Copper stuff! Refer to my video on Cleaning in the Sticky section Above.

No. 2, Is your Powder Charge, I shoot Swiss 2 and 3F powder Exclusively, I prefer to Weigh my Powder Charges By weight on a Dependable Powder Scale, I have 2 really nice Volume measures but i NEVER use them to weigh my Charges, The ONLY time i ever use them is to Find out What Volume is Weighing in Weight Grains? (This is VERY important, NEVER guess this!! Some powders Will Vary substantially in Weight vs Volume) A Volume measurer was designed to get you “Close enough” for field use, That is NOT close enough for me, I want my Powder charges to be as identical to eachother as i can possibly get them!! Whatever powder you choose, Take the time to make each Charge as identical as you possibly can to eachother, The Most Accurate way to do this is on a Beam Type Powder Scale. I get my powder charges to a 10th of a Grain of eachother. Does this really matter? I absolutely believe it does! Would you trust your Centerfire Rifle Cartridges to “Close Enough”? I sure WOULDN'T! I treat my Muzzleloaders the EXACT same way as i do my Precision Centerfire Rifles. I have Handloaded my own Custom ammo since i was 15 years old, I have setup Rifles, and Taylored handloads for MANY MANY of them, I have shot out to 800 Yards VERY SUCCESSFULLY, I could easily Hit Gallon Jugs of Water at 800 Yards With my 7Mag And Handloads. Again, i treat my Muzzleloaders the Exact same as i do my Centerfire rifles.

No. 3, Is the Over Powder Wad, I want to Create a Solid, Repeatable Gas Seal behind my bullets. I have tested Several different Over Powder wad Materials, and Thicknesses over the last few years, Cork, Vegetable Fibre, Poly, And Wool, My ABSOLUTE Favorite Material is 1/8” thick Wool Felt, it has been the Clear winner for me with every type of Bullet (Except a Minie Ball, You don’t want to use a Wad of any kind with a Hollow Base Minie)

I prefer my 1/8” Wool felt Wads to be oversize, For a .45 Cal Rifle i use .50 Cal Wool Wads, for a .50 Cal Rifle i use .54 Cal Wool Wads, and For my .54 Cal Rifles i use .58 Cal Wool Wads. You have 2 options here, You can Buy Them, The ones i Buy are Oxyoke Brand and they Come in packages of 100, You could also Buy Bulk Wool Felt Material and Punch out Your Own Wads, Durofelt online is a good place to get Wool felt in Bulk, Make sure and get the 1/8” Thick stuff, I believe that to be important.

No. 4, The next thing is Your bullets. We want our Bullets PERFECT!!! If you are a bullet Caster take the time to weigh EVERY SINGLE bullet on a dependable Scale, When you have Casted with a Particular Mold and Alloy or pure lead you will know what to expect for Bullet Weight from that Mold. Lets say your mold Throws a Bullet weight of 400 Grains with pure lead, Weigh each and every bullet after your casting session and ONLY keep the bullets that Hit your weight of 400 Grains (Remember Different Alloys will Change the Bullet weight, Along with Casting technique) I shoot for Plus or Minus 1 Grain but usually get better than that when the Mold is up to temp, and running Right. So with a Mold that is Throwing a 400 Grain Bullet of Pure Lead i will keep bullets that weigh 399.5 to 400.5, If a bullet weighs 399.4 or 400.6 it goes back in the Lead pot, Be PICKY here! As a Caster you can do this! The other thing to look for, (I learned from Lee Shaver’s) is your Bullet bases (it is the base of your bullet that steers it, NOT the Nose) Make sure your bullet Bases are “Sharp” at the Edges and Completely filled out, Meaning Completely Flat across the Mold. A common thing i see is slightly Rounded Base edges, They might all weigh the Same, But the edges are not sharp, THROW THEM BACK and re Cast until you are getting FULL “Sharp” filled out Bullet bases. Keep playing with Casting techniques until you get this Down!

If you do not Cast your own bullets and are forced to Buy them you are limited here, But stil Do the same thing with them, Weigh EVERY single bullet and Sort them. I have seen Store bought (especially casted) bullets Vary LARGELY in weight, Nothing you can do about that besides Sort Through them.

No. 5, With a pile of PERFECT Bullets the next Step is Lube, I have found Lube to be EXTREMELY important! Lube can Make, or Break a Good Bullet!! I have shot Groups that were HORRIBLE, Pie plate size and Worse, And Just by Switching Bullet Lube i have had that EXACT same bullet/load Combo Shoot a true 1” or better Group, Lube is VERY IMPORTANT! I personally make my own Bullet lube of Bear Grease (rendered bear lard) Lanolin, And Beeswax. I understand that this is Not something everyone can do, The only commercial available Lube i have tried and had REALLY good luck with is Bullshop’s NASA lube, That stuff is REALLY GOOD and i highly recommended it! You can purchase this Lube From Bullshop Bullets. Your lubing technique doesn’t matter (Pan Lube, Or By hand) just fill the Grooves evenly, When you push the Bullet down the Bore wipe off any Excess Lube that was “Cut” From the Crown of your Bore.

Once you put the Above together, Sit down at a good SOLID Bench on Sand Bags, Or Something Similar, Settle the Rifle in ROCK SOLID, make sure the Rifle Can naturally Slide When it Recoils (AVOID Lead Sled type Rests!) Once you are SOLID on a Bench, Shoot your Group.

I have had people tell me that they just can’t seem to get a Good consistent Group no matter what Bullet/powder/Wad Combo they try? One of the first things i ask is What type of Rest/Bench were They were shooting from? Was it Solid? The reason i ask this is simple, The answers i have gotten NEVER CEASE to Amaze me, Most of them were shooting off hand :lol: :lol: :lol: Here’s your SIGN Buddy!! Now what good do you think that did Besides Waste powder and Lead? You accomplished nothing!! When you are working on a Load for a Rifle, and trying to get the ABSOLUTE most out of that Gun, You need to be Shooting from a SOLID REST!! AFTER You get the Rifle/Load figured out and are Shooting Tip Top, Then by ALL means Practice Away Off Hand, etc. But for God Sake when you are trying to Develop a Load for a Rifle GET ON A SOLID BENCH! DON’T expect to Stand off hand and Drive Nails, Ever heard of human error?

Hopefully this is helpful to Folks, You have nothing to lose by trying the above? NOTHING! But possibly a WHOLE LOT to Gain! Good Luck! Aim Small, Miss Small :yeah: