Idaholewis

Well-Known Member

- Joined

- Jun 30, 2017

- Messages

- 7,287

- Reaction score

- 10,289

I have stressed over n over on here the importance of Bullet Bases being “SHARP” This is what i mean by that, The Base is what Steers the Bullet. If i were to Buy Bullets, this is a Question i would ask the Seller, Are your Bullet Bases Sharp, perfectly Filled out? Do you weigh your Bullets? If not, I would Buy Bullets elsewhere. If Accuracy is your Goal? Shooting Banged up, Battered Bullet Bases, and Mixed Bullet Weights is a WASTE of your time, Powder, and Lead. Except NOTHING but Perfect Bullet Bases, And Weights within 1 Grain of eachother. When a Bullet Mold is Up to Temp, and Running PERFECT, The Bases, and Weights will be Near DEAD ON

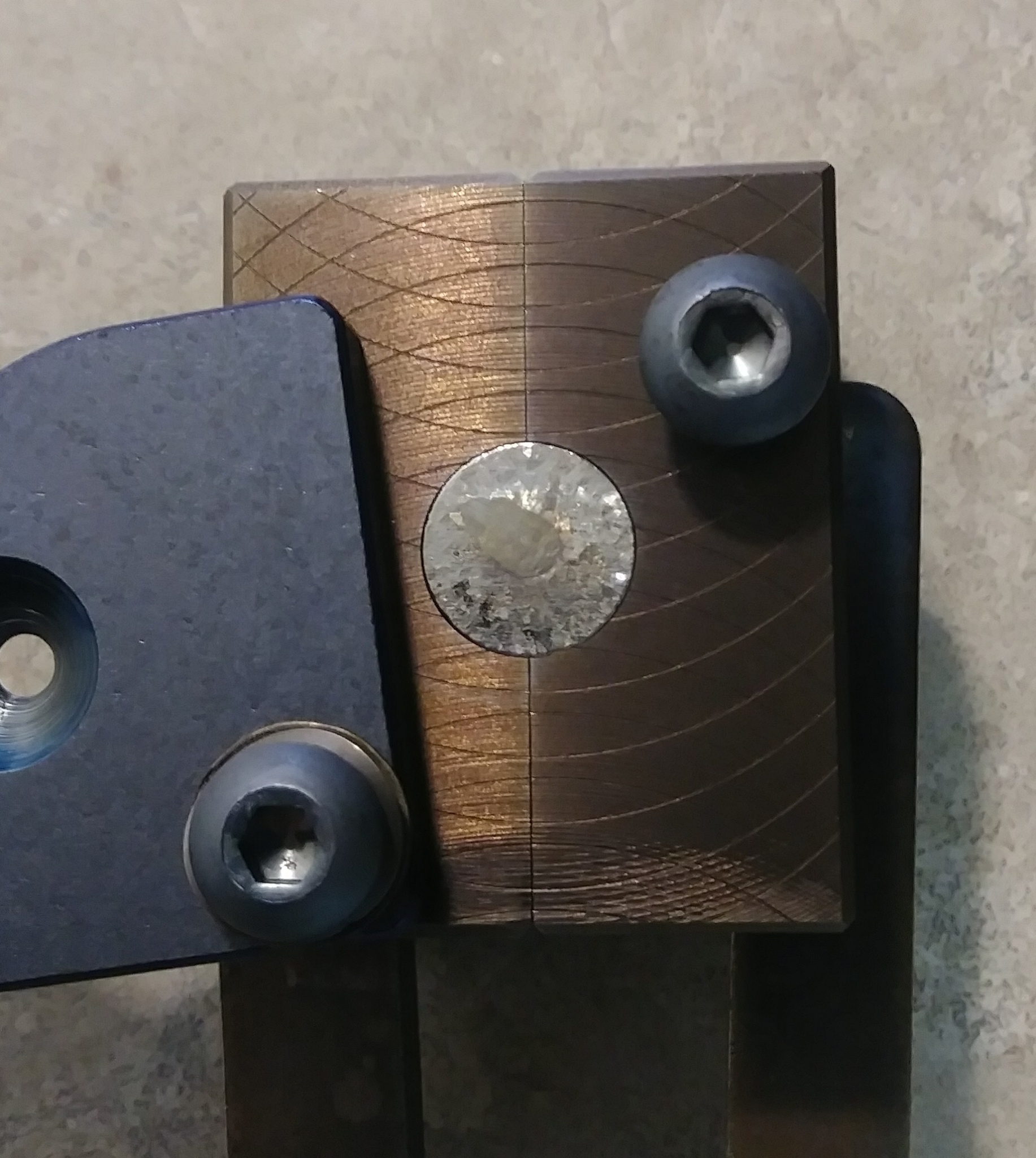

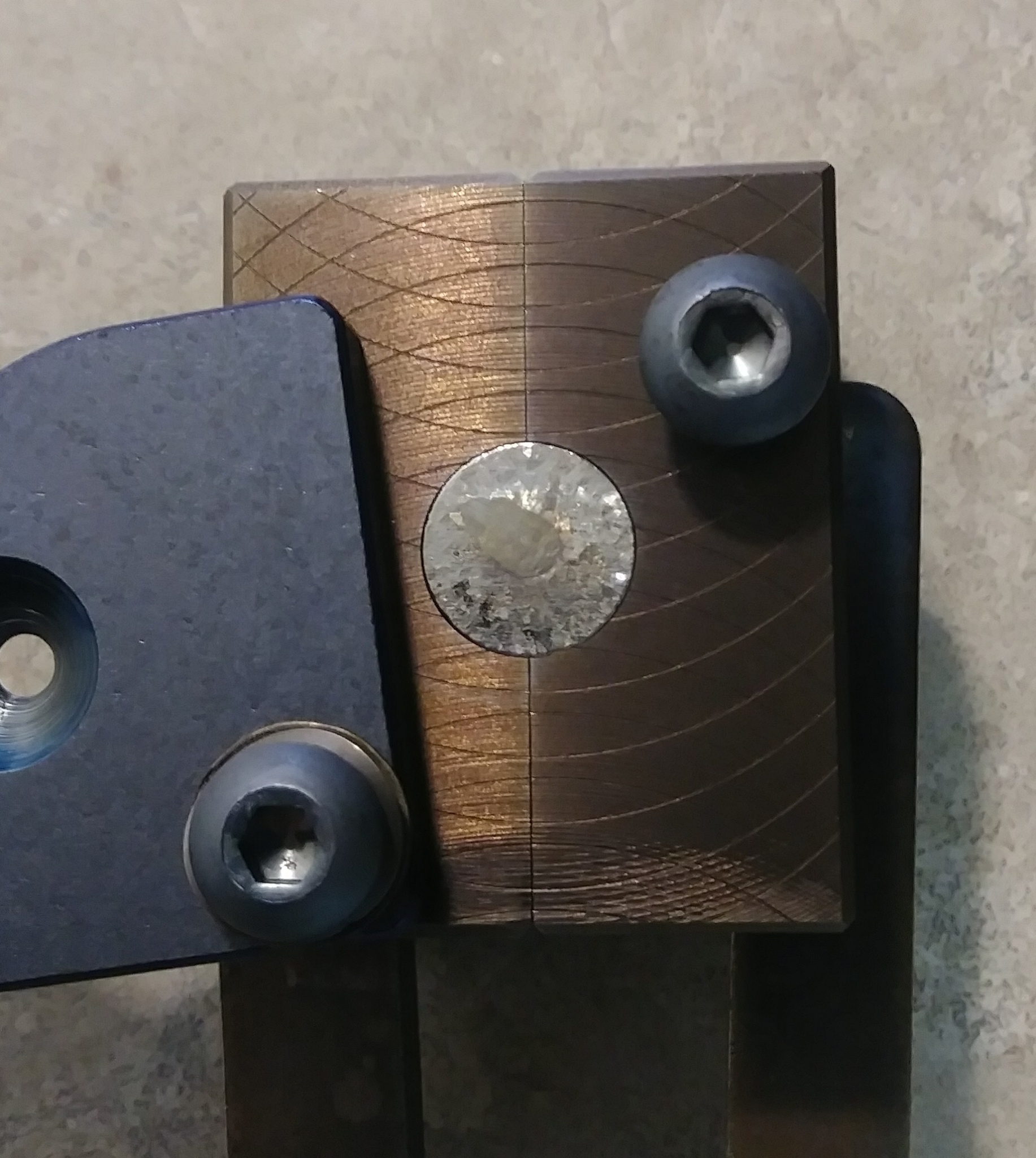

This is what you want to See when you Swing the Sprue Plate open

Here you can see the Slight “Break” Around the Edge where the Certified PURE LEAD Bullet has Shrunk ever so slightly, This is 100% Normal, Especially with PURE LEAD. Alloys Such as 1-16, 1-20, 1-30, 1-40 Will not show this as much, Will be Virtually undetectable. Simply Put, You get Better Fill Out with an Alloy

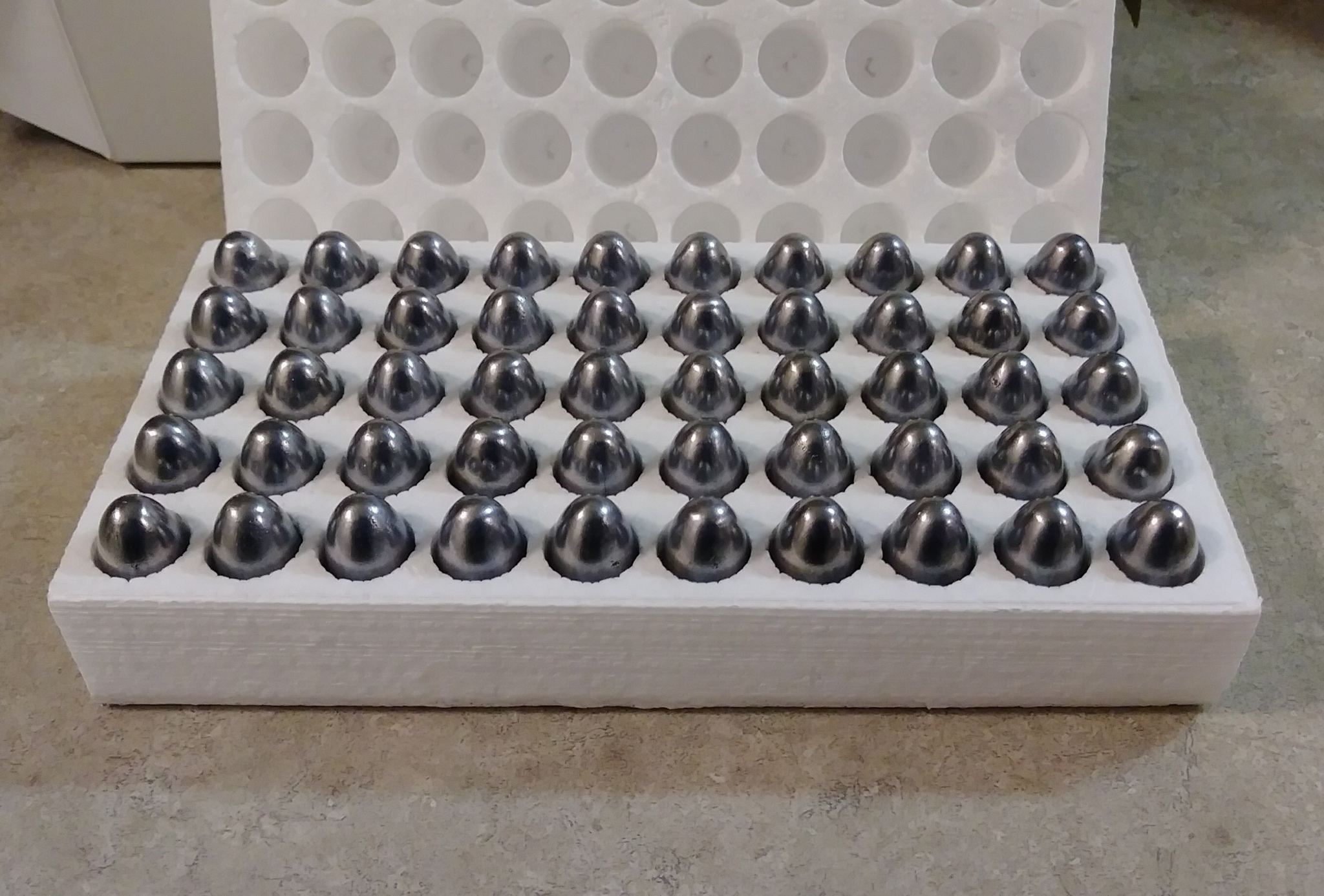

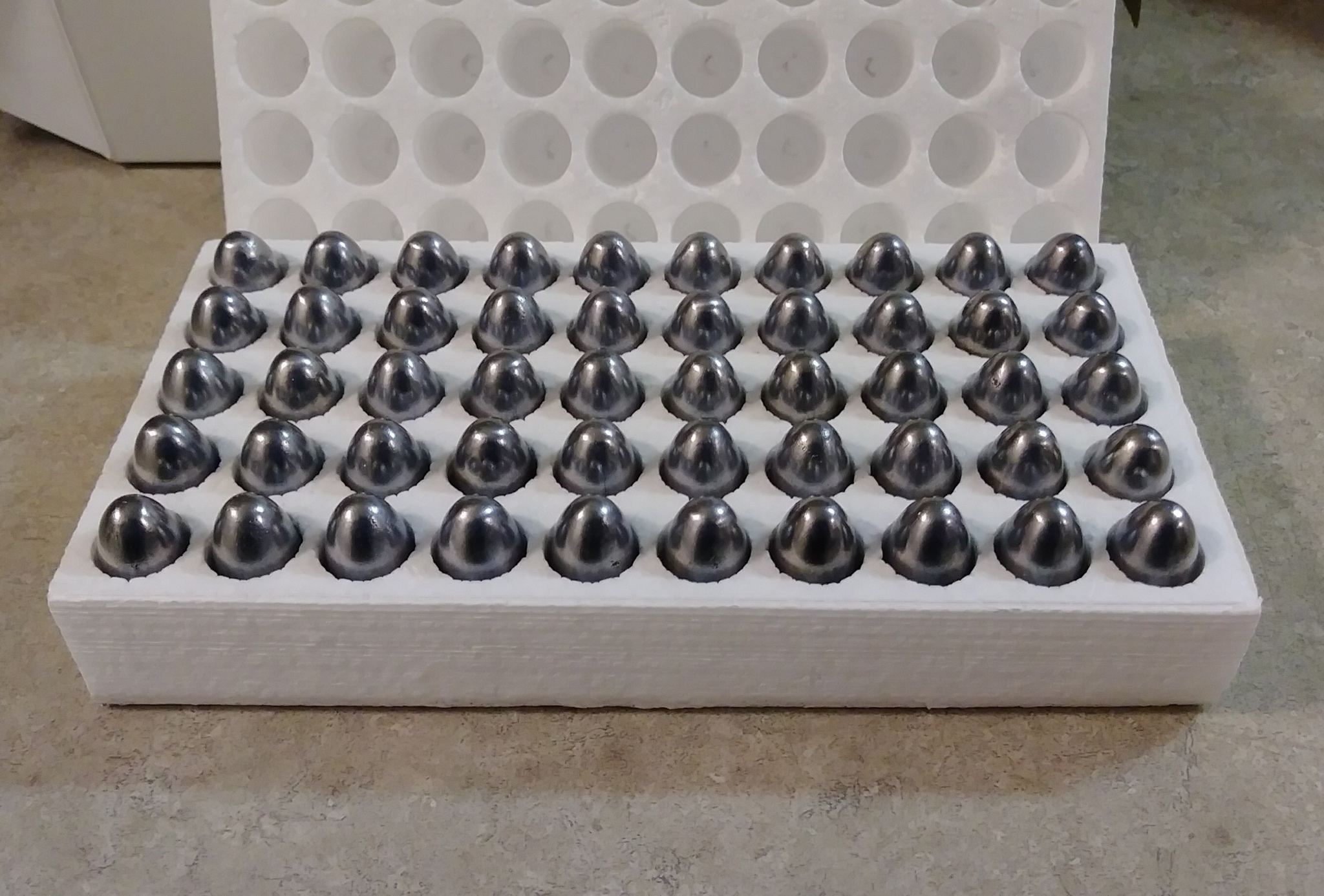

Example of PERFECT Bullet Bases, These are my Cast 420 Grain Cupped Base Paper Patch Bullet

And These are Pure Lead, If/when you Buy Bullets, this is what the Bases Should Look like. If they are Beat, and Banged up? I would look elsewhere for Bullets

Buffalo Arms Ships their Bullets in these Cartons, individually protected so they can’t be Damaged during Shipping. They Know the Importance of keeping the Bullets/Bases PERFECT

This is what you want to See when you Swing the Sprue Plate open

Here you can see the Slight “Break” Around the Edge where the Certified PURE LEAD Bullet has Shrunk ever so slightly, This is 100% Normal, Especially with PURE LEAD. Alloys Such as 1-16, 1-20, 1-30, 1-40 Will not show this as much, Will be Virtually undetectable. Simply Put, You get Better Fill Out with an Alloy

Example of PERFECT Bullet Bases, These are my Cast 420 Grain Cupped Base Paper Patch Bullet

And These are Pure Lead, If/when you Buy Bullets, this is what the Bases Should Look like. If they are Beat, and Banged up? I would look elsewhere for Bullets

Buffalo Arms Ships their Bullets in these Cartons, individually protected so they can’t be Damaged during Shipping. They Know the Importance of keeping the Bullets/Bases PERFECT