- Joined

- May 19, 2005

- Messages

- 9,205

- Reaction score

- 1,736

Thanks for the reminder, will do on this new setup.

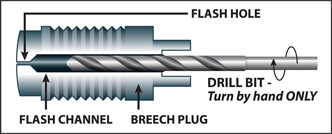

On the Vortek it would really get crudded up in the channel, not much at all in the flash hole. I bought a special bit set made just for the plug, so a light touch would cut the crud in the channel with no damage.

I hope you didn't misunderstand me. You do have to drill out the "flash channel" but I would not use any kind of metal through the "flash hole"