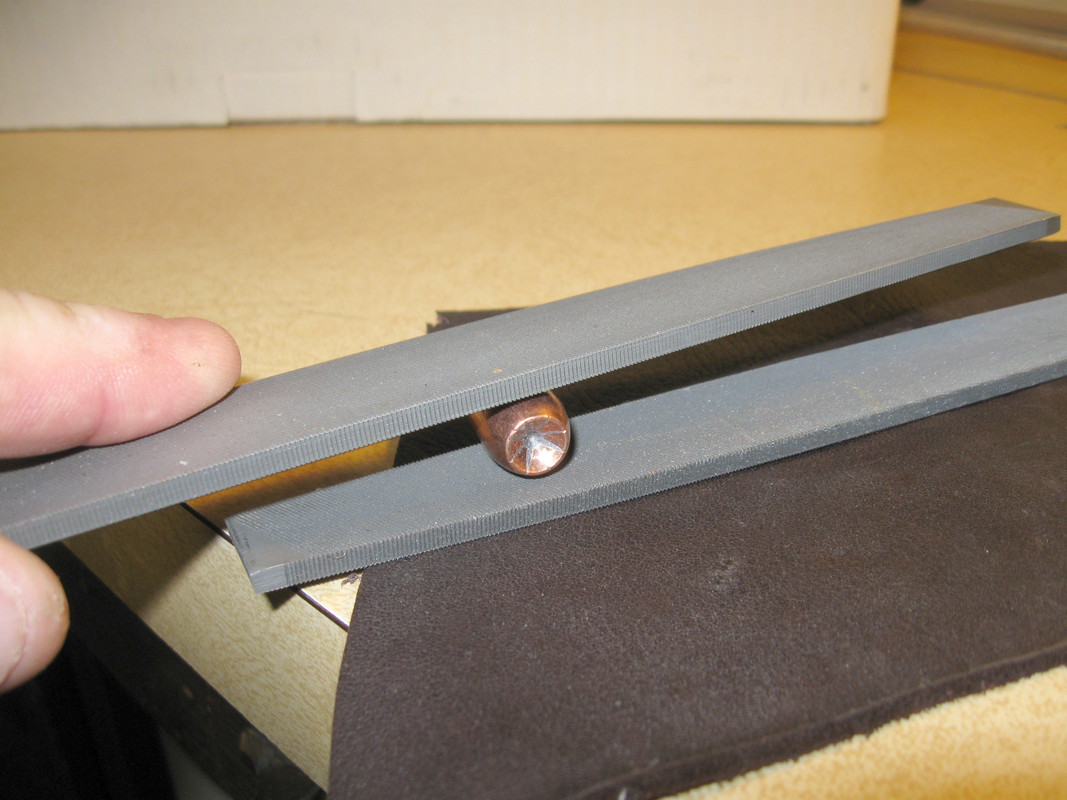

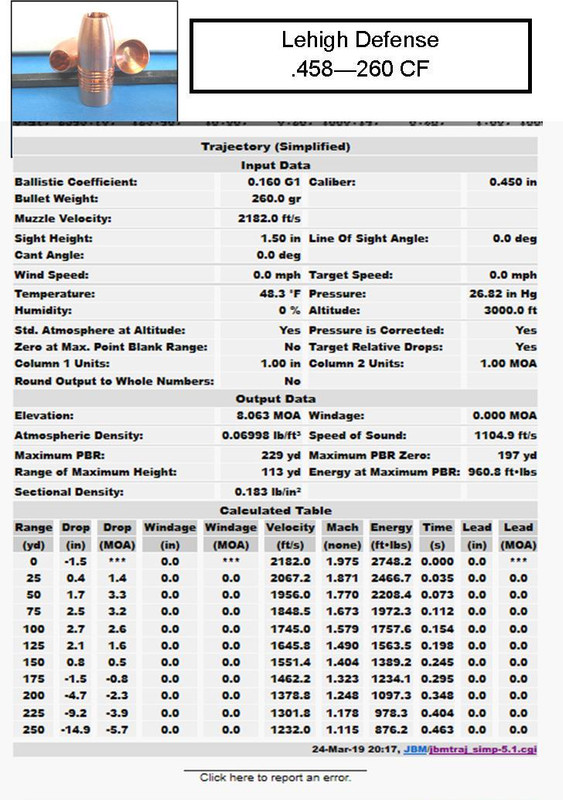

My experience with Knurling bullets is only for use inside Sabots.

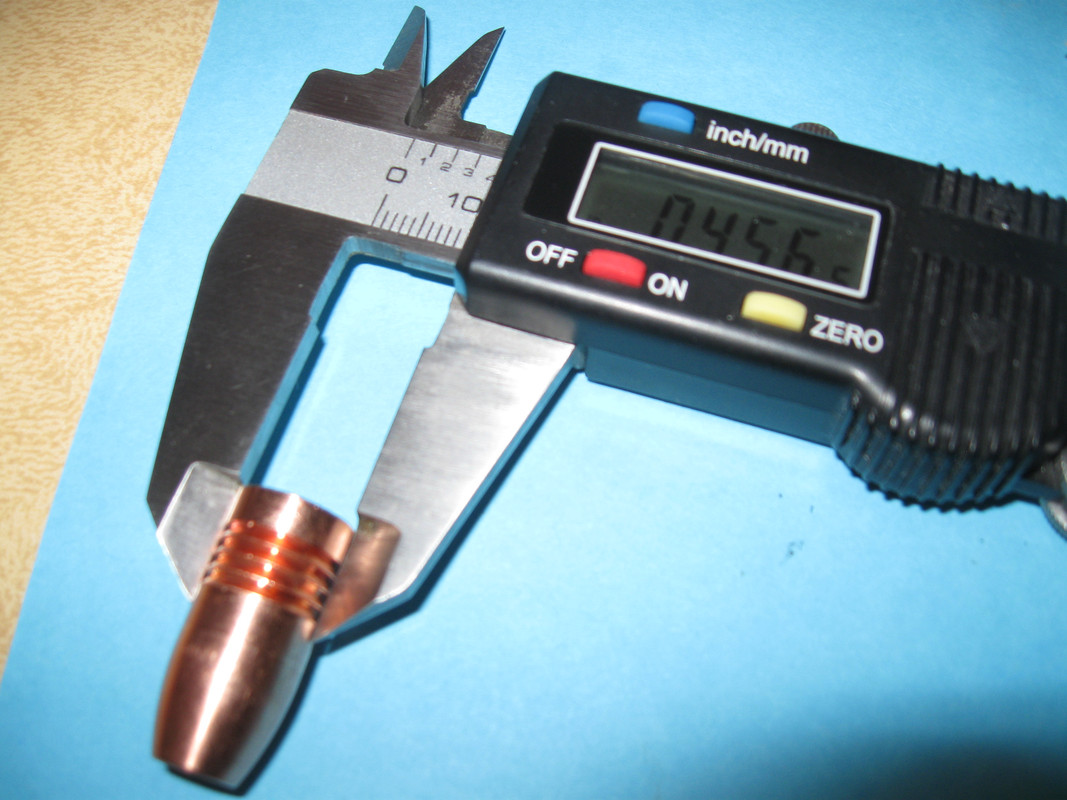

What are most peoples procedures with Bullet to Bore?

1) Heavy Knurl with Coarser Files & then run them through a Smooth Form Sizing Die?

2) Light Knurl with Finer Files to just get them to fit Tighter in the Bore? How do you stay consistent on the Finished Size?

What are most peoples procedures with Bullet to Bore?

1) Heavy Knurl with Coarser Files & then run them through a Smooth Form Sizing Die?

2) Light Knurl with Finer Files to just get them to fit Tighter in the Bore? How do you stay consistent on the Finished Size?