Made a few molds over the past 2 days and have been experimenting with them all. One of them did not come out right but the other 2 are working perfect.

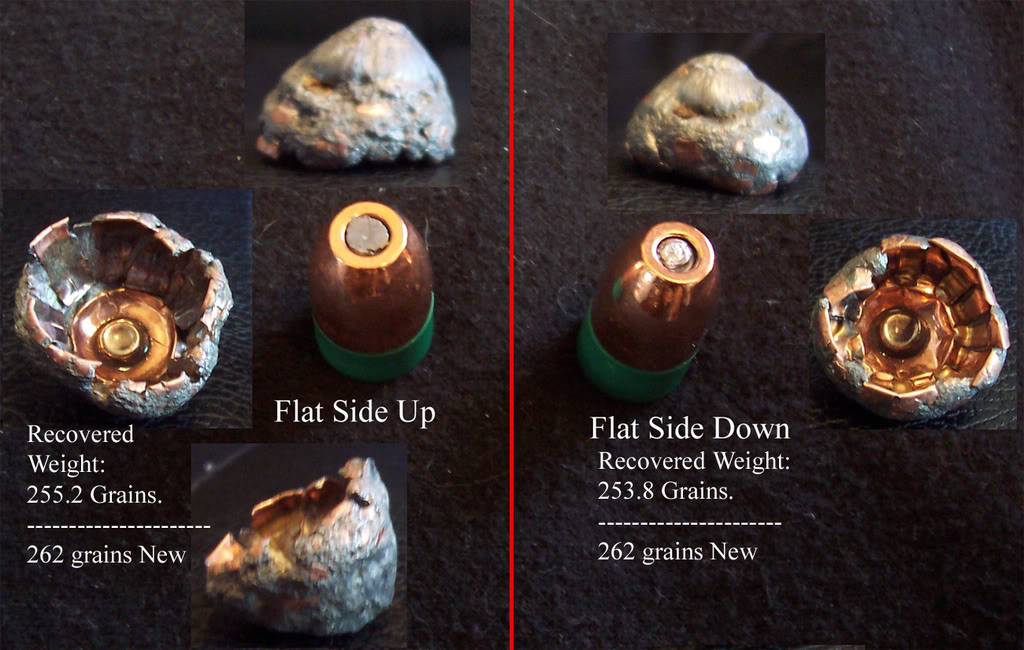

In this picture, its the Plug style insert that fits flush with the tip of the bullet. One was turned upside down with the pointy part sticking out of the bullet and the other was inserted into the bullet with the pointy part down.

These bullets weighed 245 grains out of the package and after i installed my tip, they weigh in at 262 grains. These bullets were also shot with 100 grains of Pyrodex RS @ 58 yards into damp sand. This bullet used to EXPOLODE with 90 grains RS.

You can see the tip that smeared over the nose of the bullet and protected the rest of the soft lead under it.

I still have a lot more testing to do and decide on the final design that works the best. So far this plug is really showing a lot of promise. I will work on another mold that has a slight cone that sticks out of the bullet. A litle extra to aid in protection.

Also the bullet that had the tip installed with the flat side (Sprue) had expanded more, A lot more and i'd like to see if i can improve on this and slow some of the expanding down. The other bullet worked perfectly and is super strong all the way down to the base.

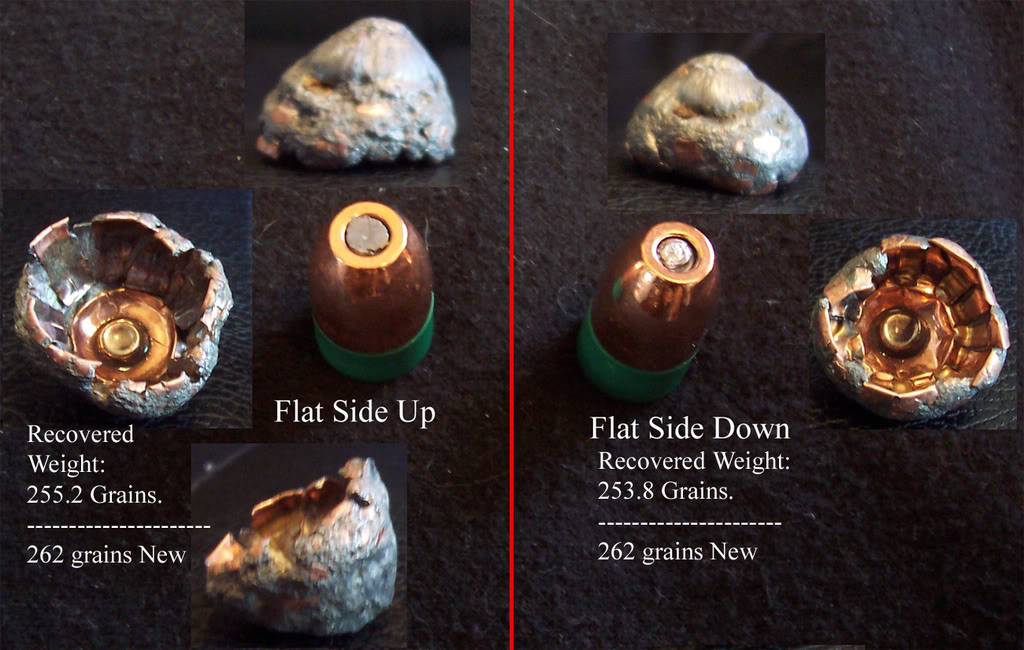

In this picture, its the Plug style insert that fits flush with the tip of the bullet. One was turned upside down with the pointy part sticking out of the bullet and the other was inserted into the bullet with the pointy part down.

These bullets weighed 245 grains out of the package and after i installed my tip, they weigh in at 262 grains. These bullets were also shot with 100 grains of Pyrodex RS @ 58 yards into damp sand. This bullet used to EXPOLODE with 90 grains RS.

You can see the tip that smeared over the nose of the bullet and protected the rest of the soft lead under it.

I still have a lot more testing to do and decide on the final design that works the best. So far this plug is really showing a lot of promise. I will work on another mold that has a slight cone that sticks out of the bullet. A litle extra to aid in protection.

Also the bullet that had the tip installed with the flat side (Sprue) had expanded more, A lot more and i'd like to see if i can improve on this and slow some of the expanding down. The other bullet worked perfectly and is super strong all the way down to the base.