johnnywadd

Member

- Joined

- Jun 29, 2011

- Messages

- 5

- Reaction score

- 0

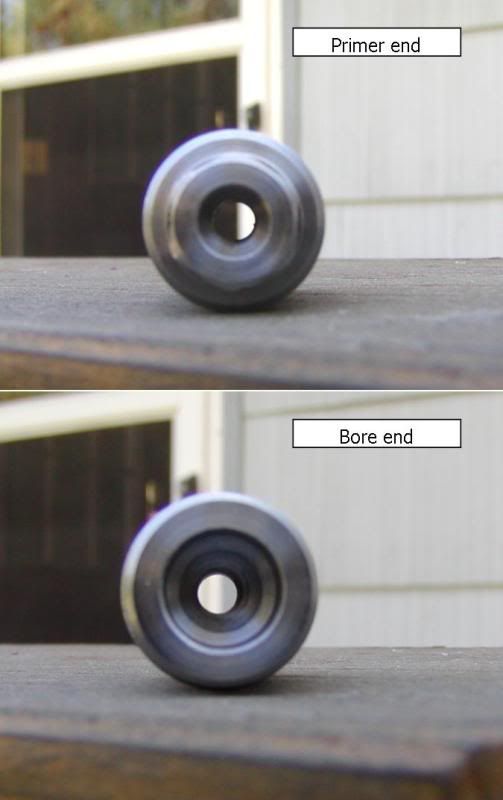

who is making the old style encore breech plugs i need some and t/c dont make them anymore

i want the old style that has a small dip in the end not the ones that has the deep pishjohnnywadd said:who is making the old style encore breech plugs i need some and t/c dont make them anymore

i was told someone on this forum was makimg the old style ss breech plugs. if anybody knows about them pm me in johnnywaddjohnnywadd said:i want the old style that has a small dip in the end not the ones that has the deep dishjohnnywadd said:who is making the old style encore breech plugs i need some and t/c dont make them anymore

It was told to me that the small dip breech plug will not ignite BH209. I have never seen this plug in my hands, but i was told the flash hole is very long, and maybe because of that, it will not ignite BH209. From what i gather, this search for the old style plug is being done by fellas that wish to shoot smokeless, and are nervous about using the new style plug after it has been converted to use a vent liner, because they want more steel between them and eternity.SJAdventures said:Being an encore owner I am curious as to the pros and cons of deep dished vs small dip.

SJAdventures said:Being an encore owner I am curious as to the pros and cons of deep dished vs small dip.

GM54-120 said:SJAdventures said:Being an encore owner I am curious as to the pros and cons of deep dished vs small dip.

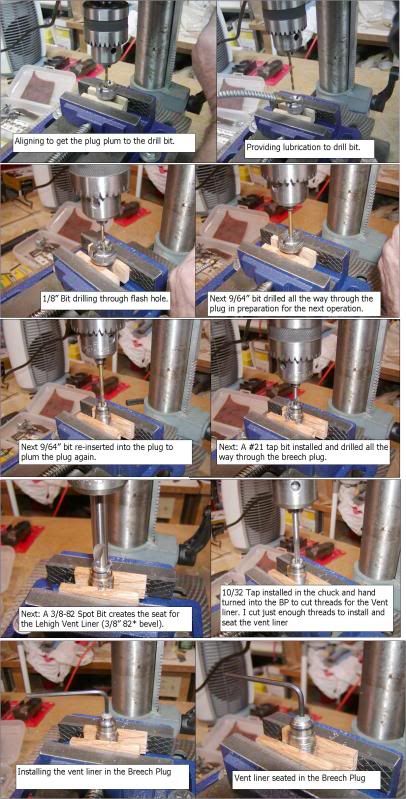

A long flash hole though would likely require more maintenance for good reliability with BH209 and the combination of heavier fouling from most 209 primers. As a plug for modding though with vent liners or other mods, you could experiment with different liner depths ect. Just like with the Accura V1 plug which has a similar dish instead of a deep pocket.

Installing a vent liner is actually a detriment, because it shortens the length of the flame channel, and steals from the volume, because of the length of the screw robbing from the flame channel length.

I see no advantage to installing a vent liner in a plug that works good as is.

To my knowledge there is no evidence, the shape of the Lehigh vent liner is an advantage. You are the only person that has ever written it has an advantage. A disadvantage of the Lehigh is the 0.032" flash hole. It seems to me, such a large hole will increase the pressure on the primer, so i guess it is a good thing that it has that dome shape, if it really does do what you write.sabotloader said:............................. but you are missing the advantage of the inverted cone on the Lehigh plug..............................................

My guess would be the Lehigh vent liner would last longer than RW, PR, and Savage vent liner, but this doesn't seem to be the case.

Enter your email address to join: