- Joined

- May 19, 2005

- Messages

- 9,205

- Reaction score

- 1,736

A forum member here posted about a new ML bullet offering from Lehigh Defense.

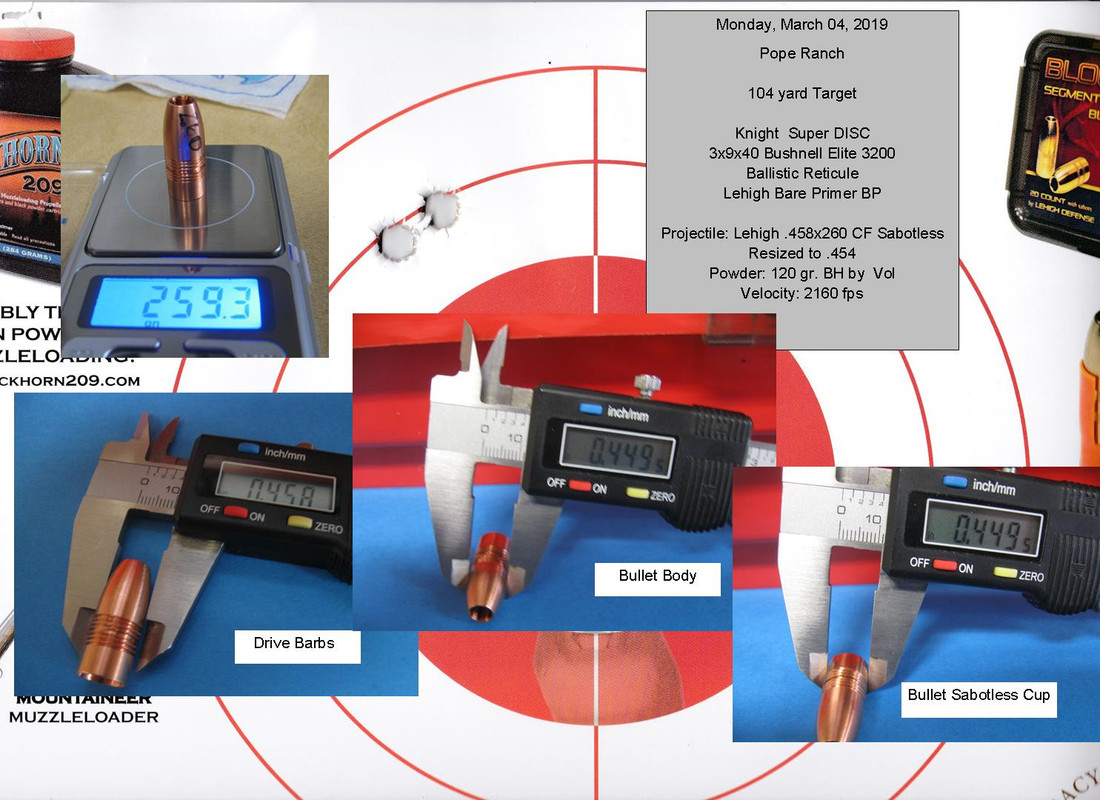

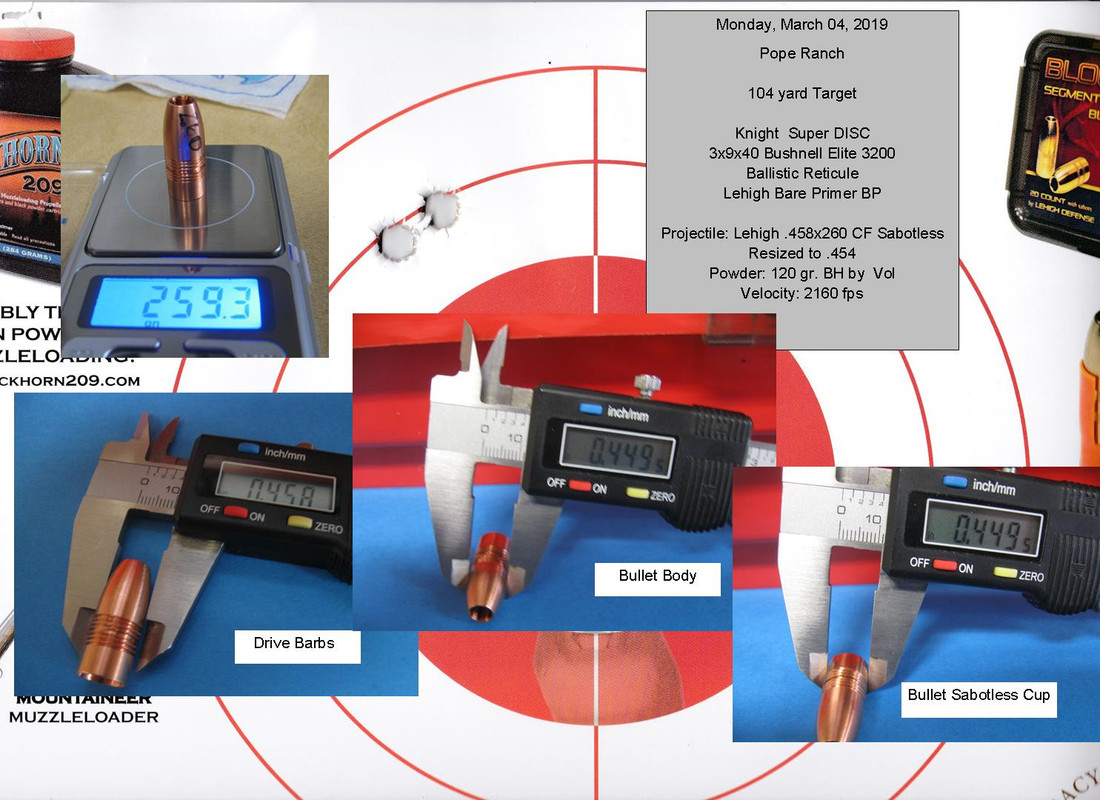

It was a .458x260CF-HP Sabotless. When I first read about it I was sure it was a mistake and should have been listed a .45x260CF. I sent an email to Lehigh and got an answer back. It is a .458 bullet, built for a true 45-70 rifle barrel. One of the reason that Lehigh went this way is that there a lot true 45-70 rifle barrels that have been converted and modified for muzzleloader application. There are 2 main differences between the true 45-70 barrel and 45 ML barrel.

1. The 45-70 rifle barrel is manufactured to much tighter tolerances than a ML barrel

2. The grooves in a 45-70 barrel are deeper than in a manufactured ML barrel.

Normally the grooves are more shallow in a ML barrel and the bore diameter can vary over a wider tolerance range. With that in mind know that the .458x260 is also built to tighter tolerances of the 45-70 barrel.

This is the new bullet inserted into the crown of my Knight 45 cal. Super DISC. I was really curious if I could load this bullet in my rifle.

My DISC measures .452 +/- from land to land, so you can see the bullet inserted into the crown. It very easily but stops at the first drive barb on the bullet. To get it through the crown it takes 2-3 really hard smacks on my short starter. Once through the crown, the bullet will then go down the bore very easily with a range rod. Almost to easy but tight enough to be gripping the lands into the grooves.

The drive barbs on a new bullet do measure .458 or with my micrometer.

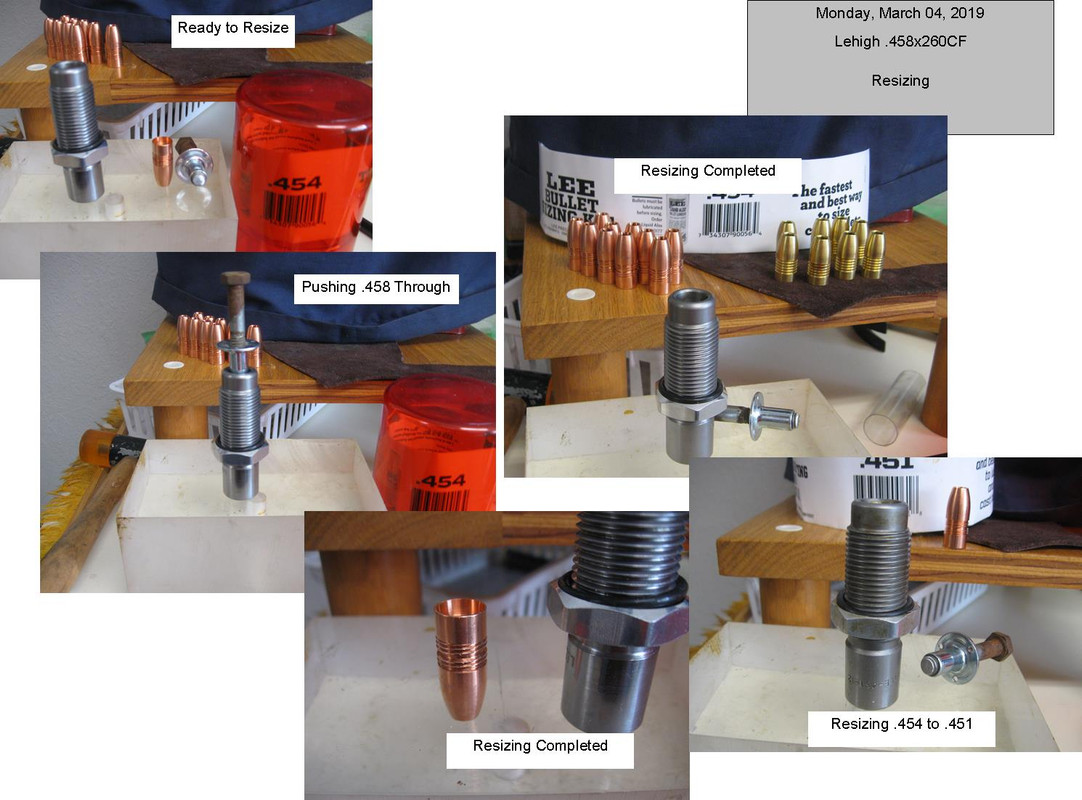

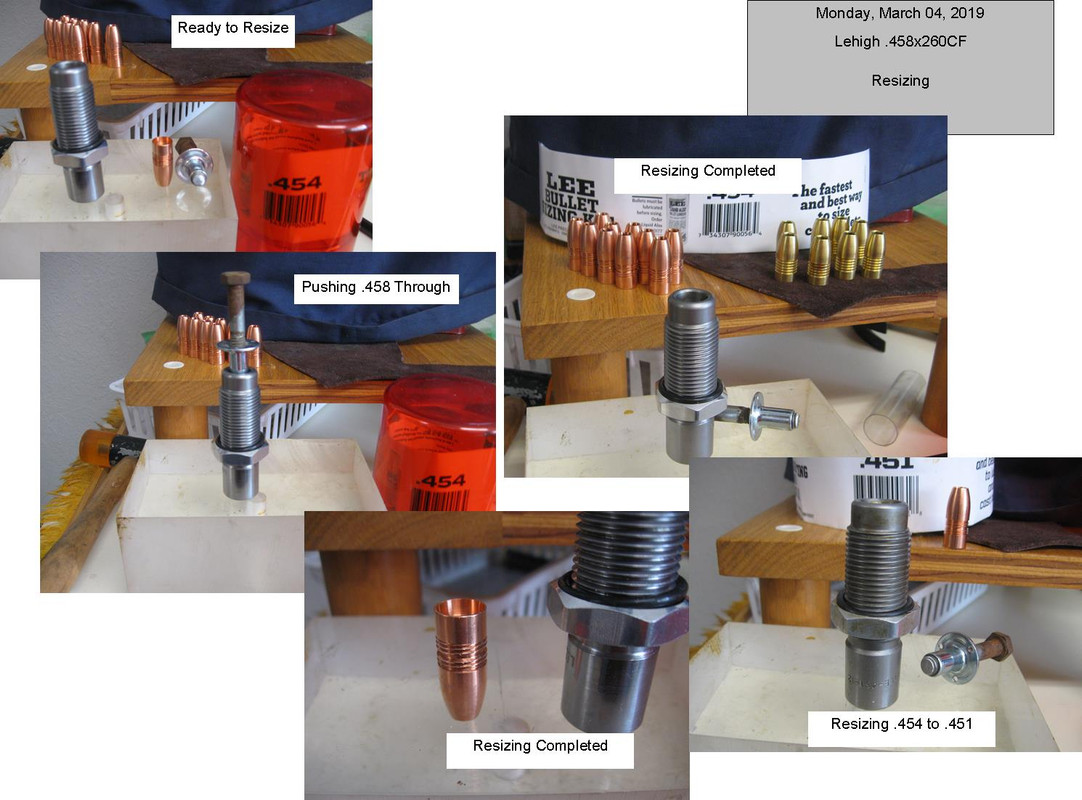

Because of the effort needed to get the bullet through the crown I wondered if I could re-size the barbs to a lesser diameter. My search for a re-sizing die lead me to an inexpensive Lee die. When I pushed the bullet through the die it did take an effort. But... it worked.

After re-sizing the bullet drive barbs were reduced to .4535. Pushing this through the crown of the rifle was greatly reduced and could be easily loaded while hunting. Still it is advantageous to use a short starter.

My next question... what about those of you that have tighter bores and they are out there... Some CVA owners have suggested their bores are .499 land to land. My next step was to re-size the .453 to .451.

With these re-sizing experiments - I really think these bullets could almost be a 'universal' or 'generic' bullet. Fitting many different 45 cal. ML's on the market.

Best part! I really believe these are excellent hunting bullets with great Terminal Performance.

I did get an opportunity to get out and so some shooting last week... I confirmed their accuracy at 100 yards and even got conned into shooting a 400 yard gong! Shot at it 3 times first shot was way off the next two went just over the top of the gong, which was good for me as I was truly guessing through the scope.

It was a .458x260CF-HP Sabotless. When I first read about it I was sure it was a mistake and should have been listed a .45x260CF. I sent an email to Lehigh and got an answer back. It is a .458 bullet, built for a true 45-70 rifle barrel. One of the reason that Lehigh went this way is that there a lot true 45-70 rifle barrels that have been converted and modified for muzzleloader application. There are 2 main differences between the true 45-70 barrel and 45 ML barrel.

1. The 45-70 rifle barrel is manufactured to much tighter tolerances than a ML barrel

2. The grooves in a 45-70 barrel are deeper than in a manufactured ML barrel.

Normally the grooves are more shallow in a ML barrel and the bore diameter can vary over a wider tolerance range. With that in mind know that the .458x260 is also built to tighter tolerances of the 45-70 barrel.

This is the new bullet inserted into the crown of my Knight 45 cal. Super DISC. I was really curious if I could load this bullet in my rifle.

My DISC measures .452 +/- from land to land, so you can see the bullet inserted into the crown. It very easily but stops at the first drive barb on the bullet. To get it through the crown it takes 2-3 really hard smacks on my short starter. Once through the crown, the bullet will then go down the bore very easily with a range rod. Almost to easy but tight enough to be gripping the lands into the grooves.

The drive barbs on a new bullet do measure .458 or with my micrometer.

Because of the effort needed to get the bullet through the crown I wondered if I could re-size the barbs to a lesser diameter. My search for a re-sizing die lead me to an inexpensive Lee die. When I pushed the bullet through the die it did take an effort. But... it worked.

After re-sizing the bullet drive barbs were reduced to .4535. Pushing this through the crown of the rifle was greatly reduced and could be easily loaded while hunting. Still it is advantageous to use a short starter.

My next question... what about those of you that have tighter bores and they are out there... Some CVA owners have suggested their bores are .499 land to land. My next step was to re-size the .453 to .451.

With these re-sizing experiments - I really think these bullets could almost be a 'universal' or 'generic' bullet. Fitting many different 45 cal. ML's on the market.

Best part! I really believe these are excellent hunting bullets with great Terminal Performance.

I did get an opportunity to get out and so some shooting last week... I confirmed their accuracy at 100 yards and even got conned into shooting a 400 yard gong! Shot at it 3 times first shot was way off the next two went just over the top of the gong, which was good for me as I was truly guessing through the scope.

Last edited by a moderator: