Idaholewis

Well-Known Member

- Joined

- Jun 30, 2017

- Messages

- 7,287

- Reaction score

- 10,289

This probably belongs somewhere else? But since most of my posting is here, i figured I would start a thread on Onion Skin Paper For Patching bullets. The weight is how much 500 sheets is suppose to weigh, As far as thickness to weight it definitely varies

First off i will state i am NO EXPERT at fraction stuff! But i think you will understand what i am saying here, i might have a 0 or . In the wrong place?

I just recently picked up 2 reams (500 sheets a piece) This is the old 25% Cotton stuff, Cockle texture. Both of these measure 0.002 in thickness, 2 wraps of this paper ads .008 to the overall bullet Diameter. The thinnest stuff i have measured is the wood fiber stuff from the Paper mill store online, i measured it at 0.0175, I have heard of 0.0150, But I have not personally seen any that thin, it might have been Ron that told me he has some 0.0150 stuff? From what little I’ve seen personally, and read about, it seems that 0.0175 to 0.002 is more the Norm?

2 wraps of Paper that measures 0.0150 thickness would ad .006 to the overall bullet Diameter, In other words a bullet that is .492 in diameter, with 2 wraps of this paper would end up at .498

2 wraps of Paper that measures 0.0175 thickness would ad .007 to the overall bullet Diameter, a bullet measuring .492 in diameter, with 2 wraps of this paper would end up at .499

And 2 wraps of paper that measures 0.002 thickness would ad .008 to the overall bullet Diameter, a bullet measuring .492 in diameter, with 2 wraps of this paper would end up at .500

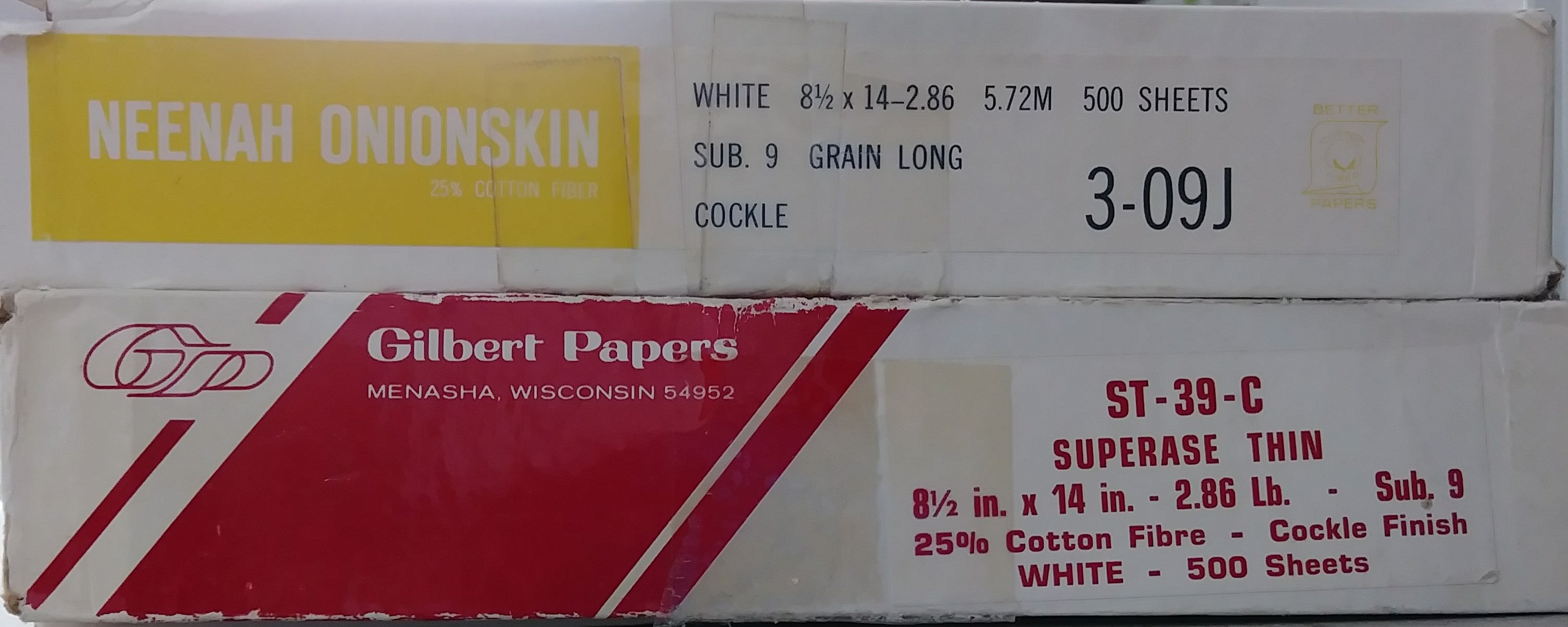

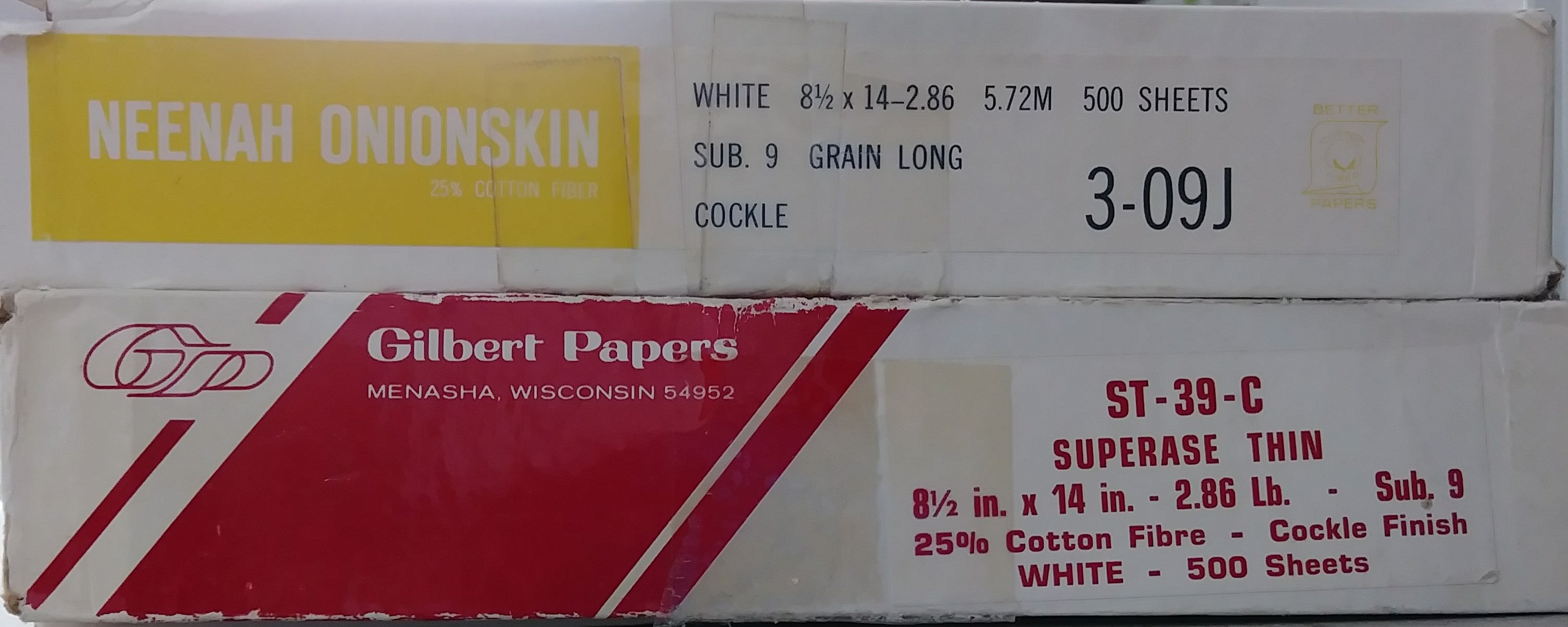

These are the 2 Reams of paper I recently picked up, Anyone familiar with these 2 brands? I know there are several old brands out there, Eaton, Southworth, etc. etc.

First off i will state i am NO EXPERT at fraction stuff! But i think you will understand what i am saying here, i might have a 0 or . In the wrong place?

I just recently picked up 2 reams (500 sheets a piece) This is the old 25% Cotton stuff, Cockle texture. Both of these measure 0.002 in thickness, 2 wraps of this paper ads .008 to the overall bullet Diameter. The thinnest stuff i have measured is the wood fiber stuff from the Paper mill store online, i measured it at 0.0175, I have heard of 0.0150, But I have not personally seen any that thin, it might have been Ron that told me he has some 0.0150 stuff? From what little I’ve seen personally, and read about, it seems that 0.0175 to 0.002 is more the Norm?

2 wraps of Paper that measures 0.0150 thickness would ad .006 to the overall bullet Diameter, In other words a bullet that is .492 in diameter, with 2 wraps of this paper would end up at .498

2 wraps of Paper that measures 0.0175 thickness would ad .007 to the overall bullet Diameter, a bullet measuring .492 in diameter, with 2 wraps of this paper would end up at .499

And 2 wraps of paper that measures 0.002 thickness would ad .008 to the overall bullet Diameter, a bullet measuring .492 in diameter, with 2 wraps of this paper would end up at .500

These are the 2 Reams of paper I recently picked up, Anyone familiar with these 2 brands? I know there are several old brands out there, Eaton, Southworth, etc. etc.