Finally was able to get to this CVA Hawken .54cal that both my dad and I built for my brother a number of years ago. The muzzle was always super sharp and squared off so that loading a patched round ball was... well.... a REAL pain in the ass. It was so squared off that it would cut the patch when loading it up.

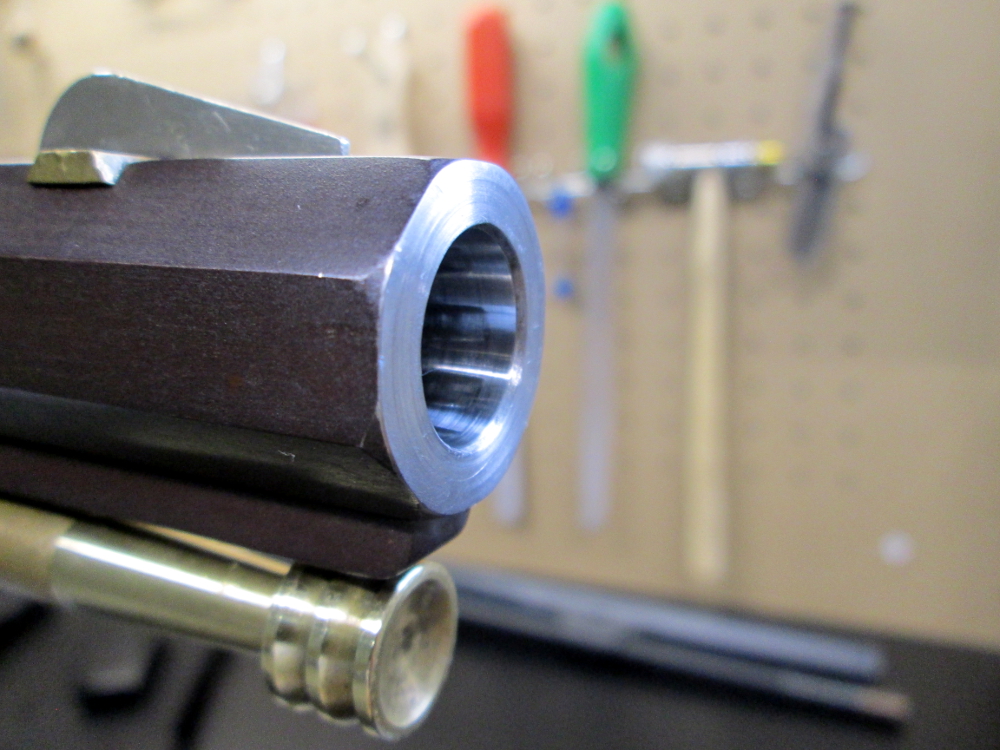

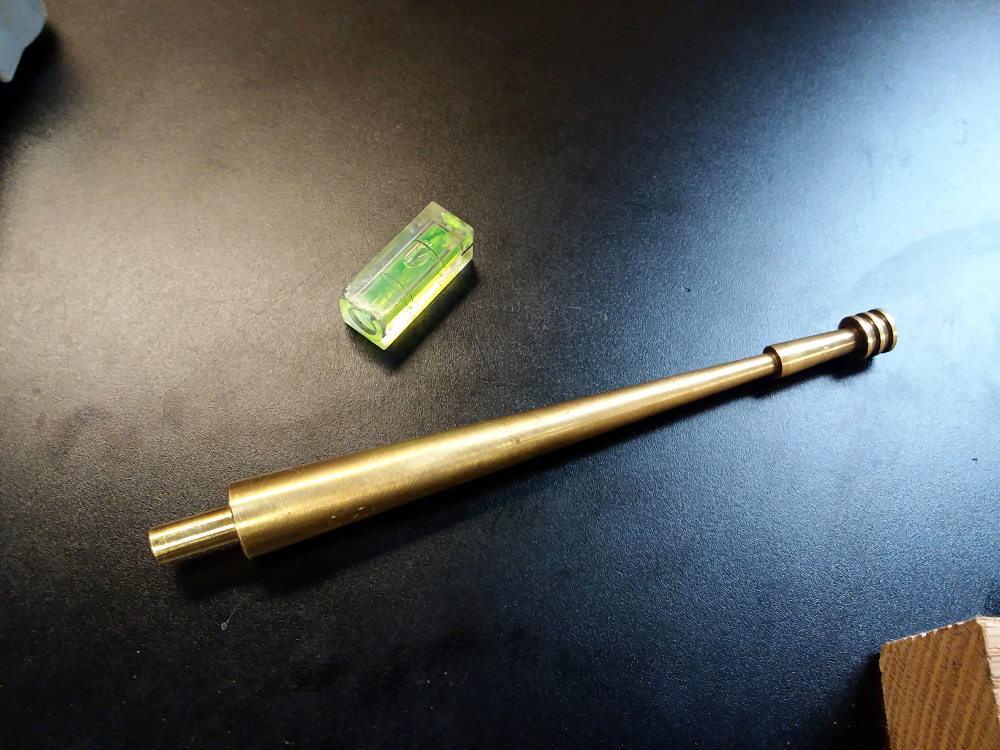

You can see how terrible that crown was, just completely square, no nice taper to ease strain at the muzzle while loading.

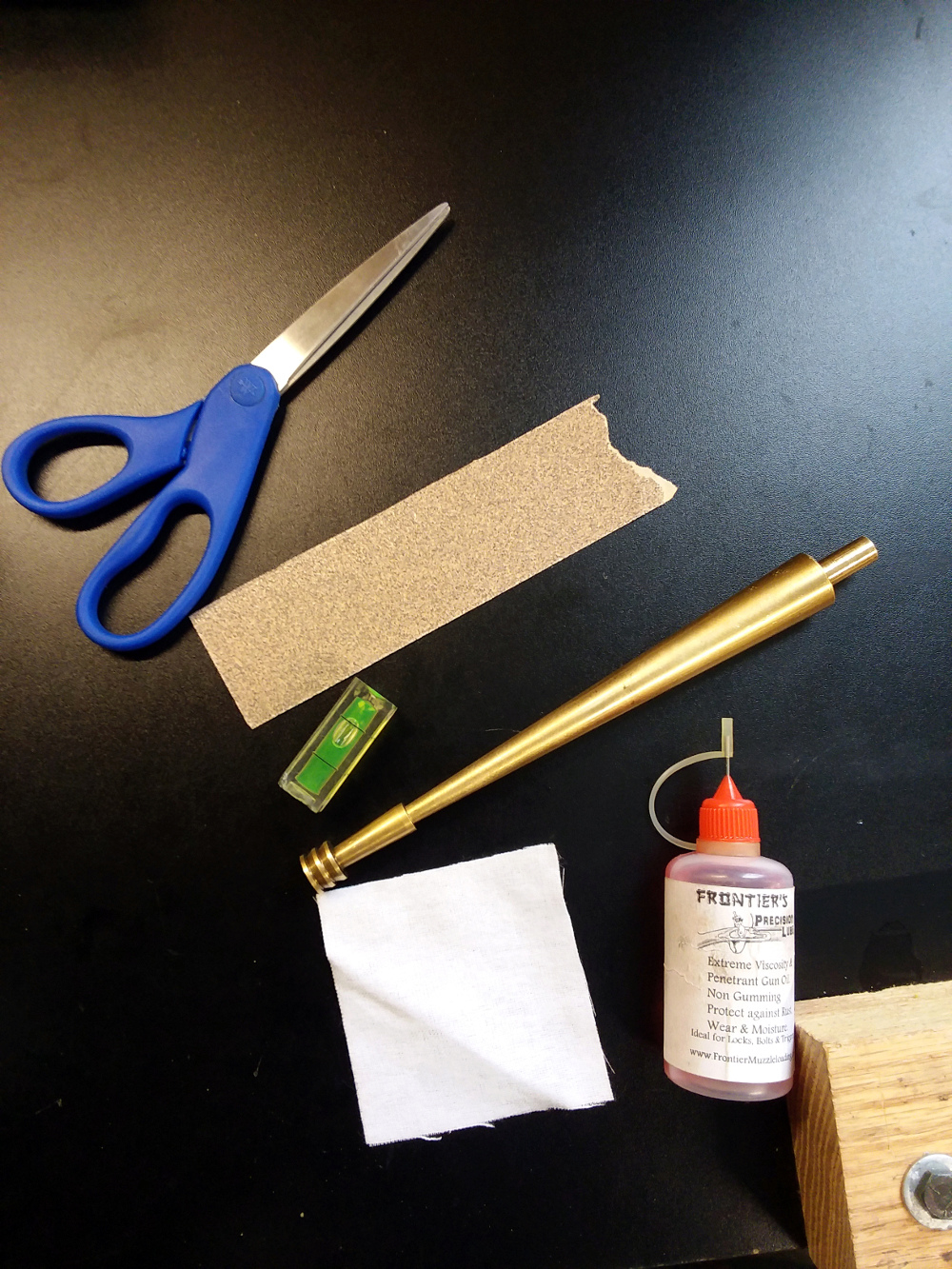

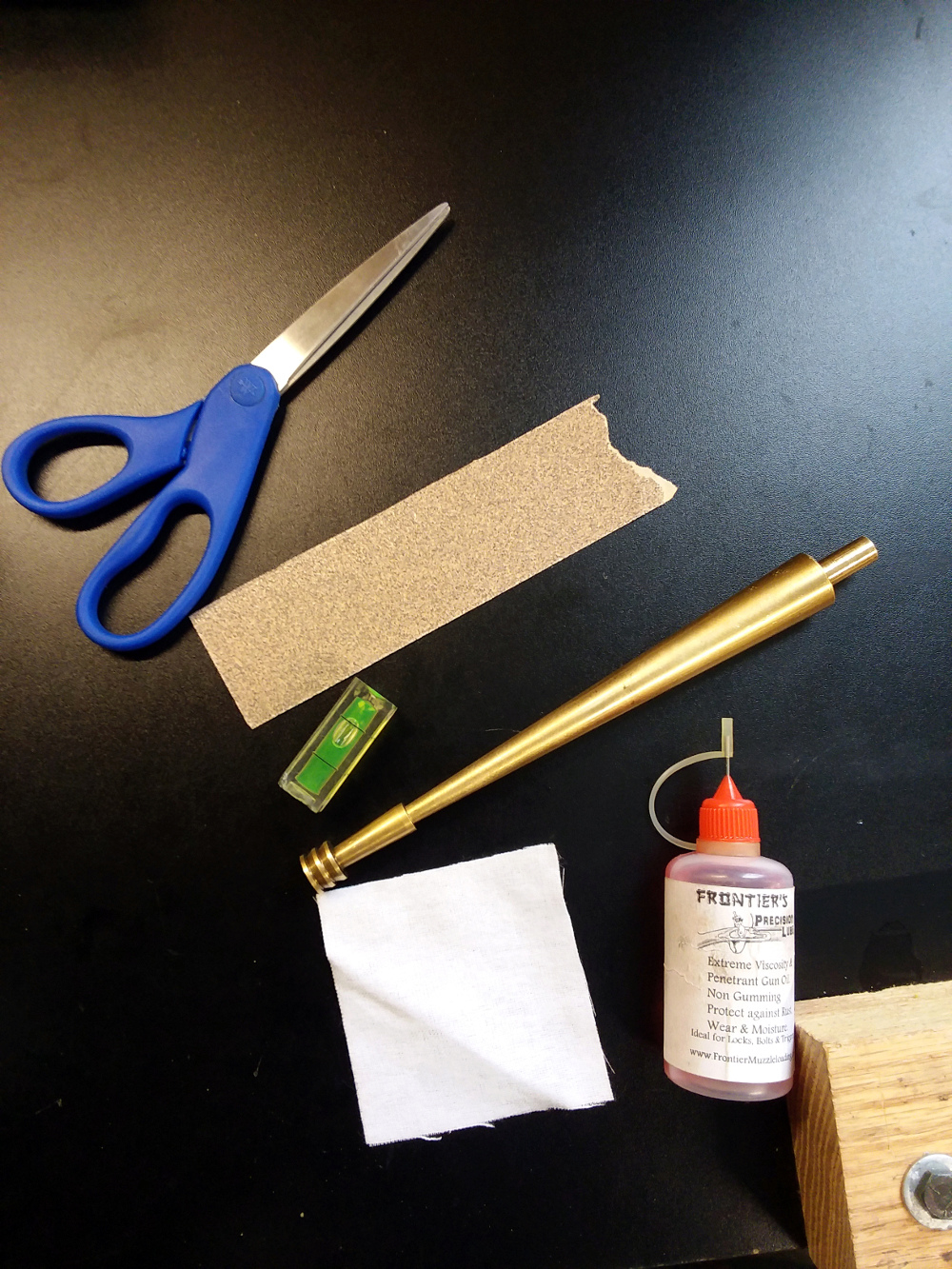

I broke out the coning tool and supplies and went to work. I did use a power drill this time, but was very careful with it. You can do a lot of damage with its power and weight.

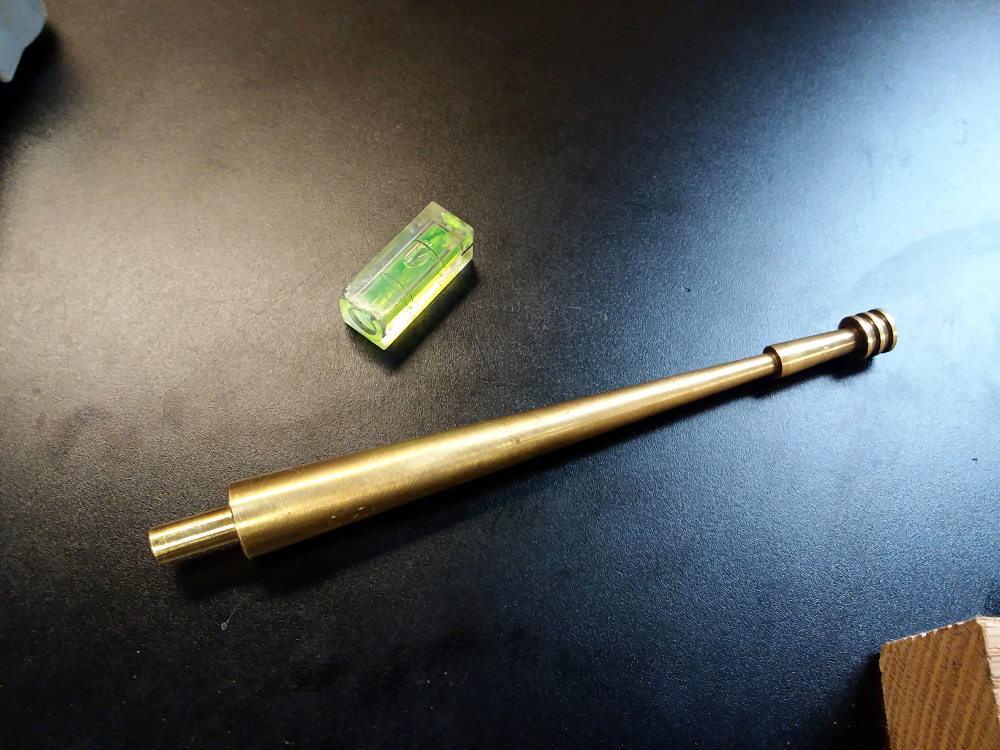

A little lubricating oil helps keep the shavings at the top. Anything else that drops down, will hit the oiled bore and patch that surrounds the jag. The point behind the jag is to center the coning device.

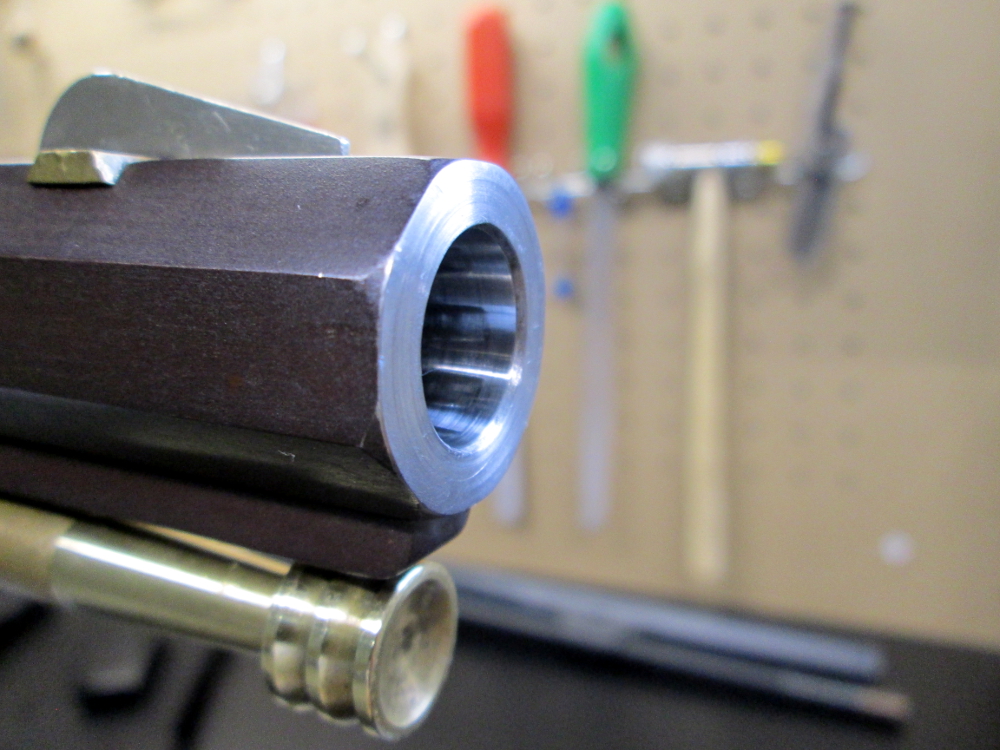

Finished project, just needs to have around 50 shots put down range with some shoot out patch lube & bore enhancer and she will be set. In the end, I can take a .530" round ball and a .020" patch, place it over the muzzle and with my thumb and a little wrist muscle, push the ball almost flush with the muzzle. I don't want it to load super easy, just enough to eliminate the need of a short starter and most importantly, keep the patch from being cut at the muzzle.

You can see how terrible that crown was, just completely square, no nice taper to ease strain at the muzzle while loading.

I broke out the coning tool and supplies and went to work. I did use a power drill this time, but was very careful with it. You can do a lot of damage with its power and weight.

A little lubricating oil helps keep the shavings at the top. Anything else that drops down, will hit the oiled bore and patch that surrounds the jag. The point behind the jag is to center the coning device.

Finished project, just needs to have around 50 shots put down range with some shoot out patch lube & bore enhancer and she will be set. In the end, I can take a .530" round ball and a .020" patch, place it over the muzzle and with my thumb and a little wrist muscle, push the ball almost flush with the muzzle. I don't want it to load super easy, just enough to eliminate the need of a short starter and most importantly, keep the patch from being cut at the muzzle.