- Joined

- May 19, 2005

- Messages

- 9,205

- Reaction score

- 1,736

The weather here was not good today rain and high winds... Not good for shooting

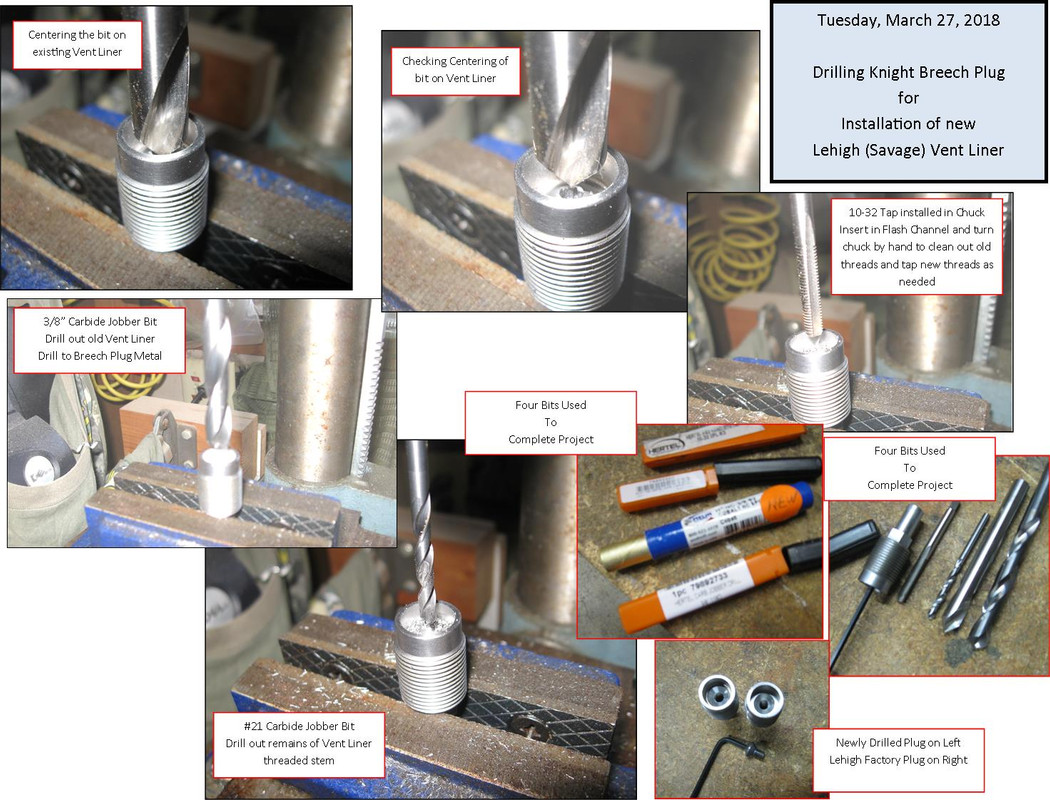

For something to do I decided I would tackle the replacement of a Knight Vent Liner in the breech plug. I had collected the bits needed - I just did not have lathe to do it on! A fellow ML shooter here in Moscow has one and I was planning on him and I doing the project together, but his lathe was on the fritz! So I decided I would use my drill press in the wood shop.

Heated the shop up and began the project. The first step in the project was to insure the drill press table was perpendicular to the chuck. Use a long drill in the chuck and a square to the table to 90*

Also - I felt it was important to slow the drill press to it lowest speed to reduce heat and provide more control. So I move it down to 640rpm.

Next I inserted a the 3/8" mill end bit in the chuck and the Breech plug in the table vice. Then I centered the drill on the hole in the vent liner. Pulled the bit down to the hole and turned the chuck by hand to confirm the etching on the vent line was equal.

After the operation began.

Placed the 3/8" Carbide Jobbers bit in the chuck and started the drilling operation. I would only drill for a few seconds and lif the bit up and out. Using compressed air I would blow the BP out and observe my progress. The observations were to insure that I was only drill Vent Liner - I did not want to drill in to the BP metal. Repeated the drill and observe steps several time. Finally I thought I could feel the bit touch the BP metal as the bit turned easier and more smooth.

Remove the Carbide bit and insterted the 3/8 x 82* bevel Mill end and cut the seat for the new Vent Liner.

Remove the Mill bit and Install a #21 Carbide Wire bit to drill out the old Vent Liner Stem to the BP flash Channel

Remove the #21 bit and install the 10x32 Tap in the chuck. Lower the Tap to the hole insert the tap and turn the chuck by hand to clean out the old existing threads and to cut a few additional threads in the BP.

Remove move bit from BP and BP from vice. Install a new Lehigh Savage Vent Liner and test for fit... All is good

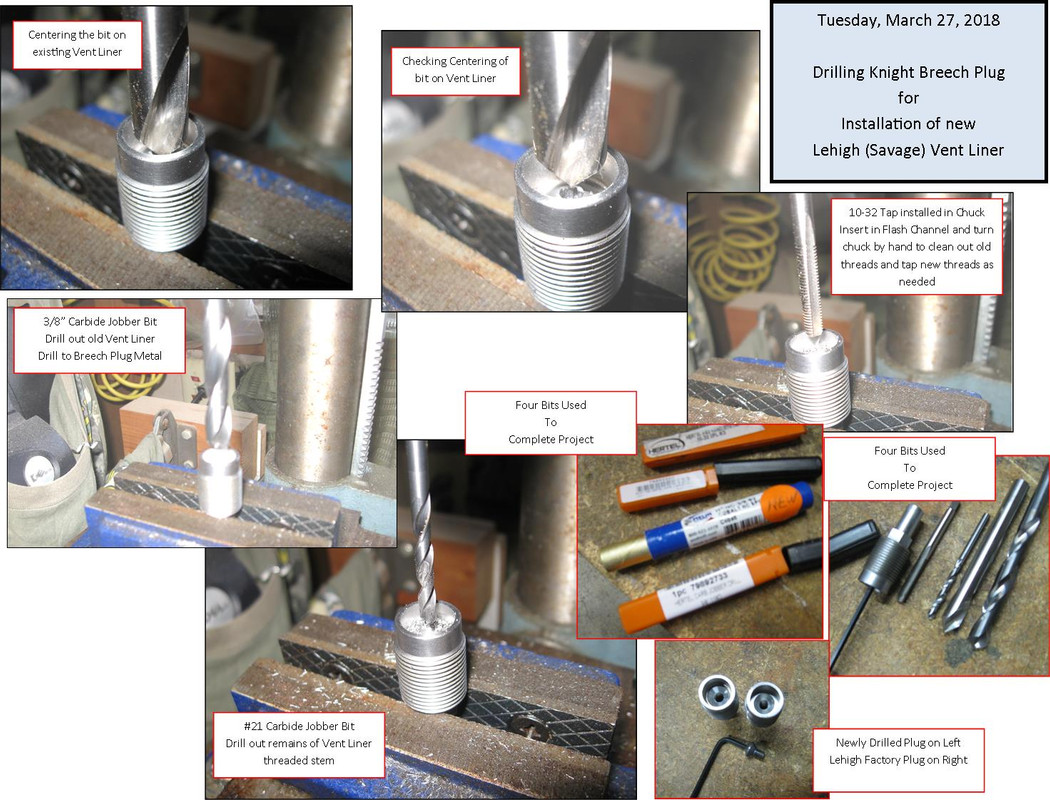

He is a composite pic of the operation

Some additional pictures that might be hard to see in the Composite

This is the new Lehigh Savage Vent Liner

Project BP on the Left a new Lehigh Breech Plug on the right.

This whole operation turned out to be much easier than I expected.

For something to do I decided I would tackle the replacement of a Knight Vent Liner in the breech plug. I had collected the bits needed - I just did not have lathe to do it on! A fellow ML shooter here in Moscow has one and I was planning on him and I doing the project together, but his lathe was on the fritz! So I decided I would use my drill press in the wood shop.

Heated the shop up and began the project. The first step in the project was to insure the drill press table was perpendicular to the chuck. Use a long drill in the chuck and a square to the table to 90*

Also - I felt it was important to slow the drill press to it lowest speed to reduce heat and provide more control. So I move it down to 640rpm.

Next I inserted a the 3/8" mill end bit in the chuck and the Breech plug in the table vice. Then I centered the drill on the hole in the vent liner. Pulled the bit down to the hole and turned the chuck by hand to confirm the etching on the vent line was equal.

After the operation began.

Placed the 3/8" Carbide Jobbers bit in the chuck and started the drilling operation. I would only drill for a few seconds and lif the bit up and out. Using compressed air I would blow the BP out and observe my progress. The observations were to insure that I was only drill Vent Liner - I did not want to drill in to the BP metal. Repeated the drill and observe steps several time. Finally I thought I could feel the bit touch the BP metal as the bit turned easier and more smooth.

Remove the Carbide bit and insterted the 3/8 x 82* bevel Mill end and cut the seat for the new Vent Liner.

Remove the Mill bit and Install a #21 Carbide Wire bit to drill out the old Vent Liner Stem to the BP flash Channel

Remove the #21 bit and install the 10x32 Tap in the chuck. Lower the Tap to the hole insert the tap and turn the chuck by hand to clean out the old existing threads and to cut a few additional threads in the BP.

Remove move bit from BP and BP from vice. Install a new Lehigh Savage Vent Liner and test for fit... All is good

He is a composite pic of the operation

Some additional pictures that might be hard to see in the Composite

This is the new Lehigh Savage Vent Liner

Project BP on the Left a new Lehigh Breech Plug on the right.

This whole operation turned out to be much easier than I expected.