Idaholewis

Well-Known Member

- Joined

- Jun 30, 2017

- Messages

- 7,287

- Reaction score

- 10,288

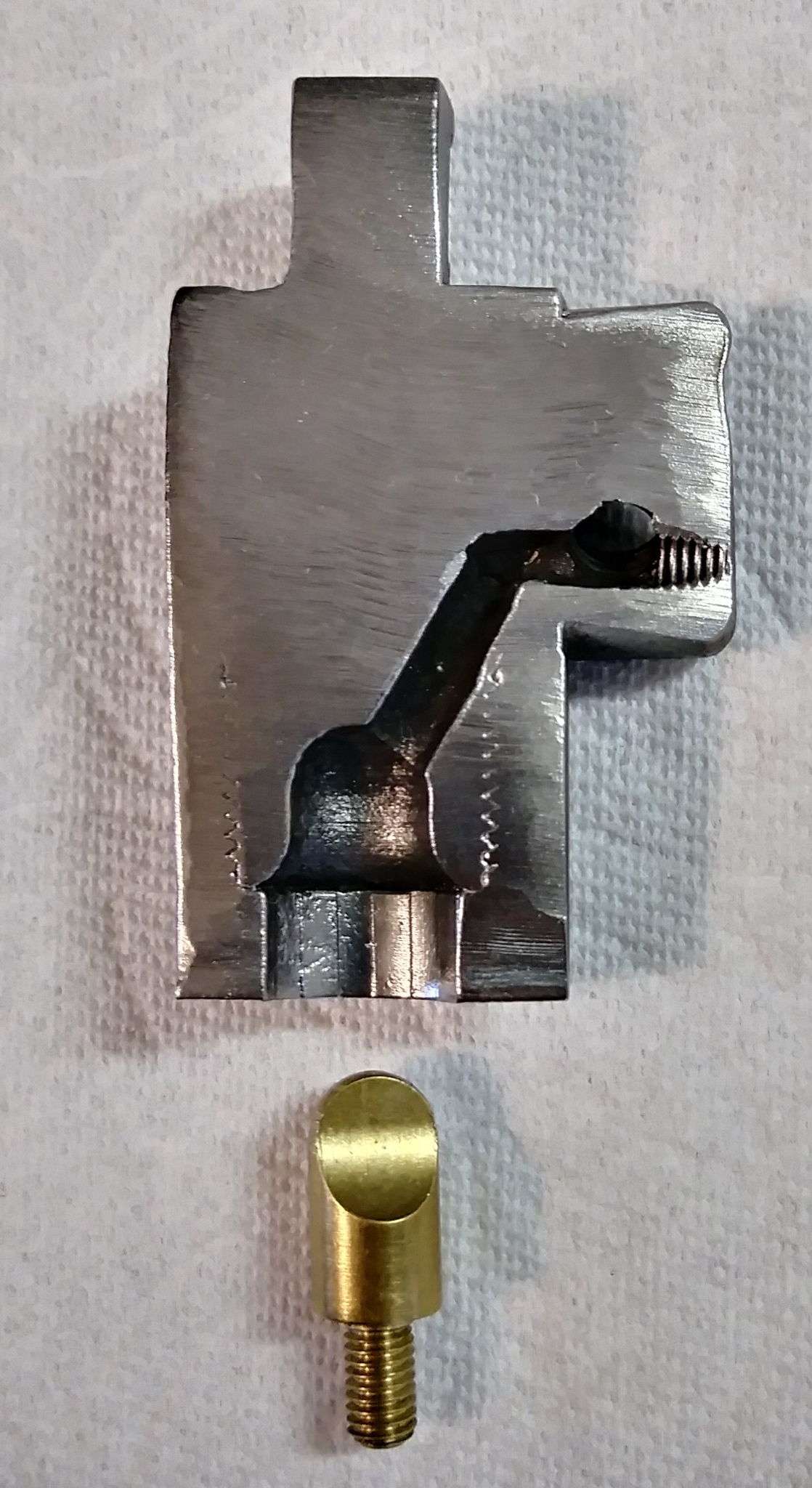

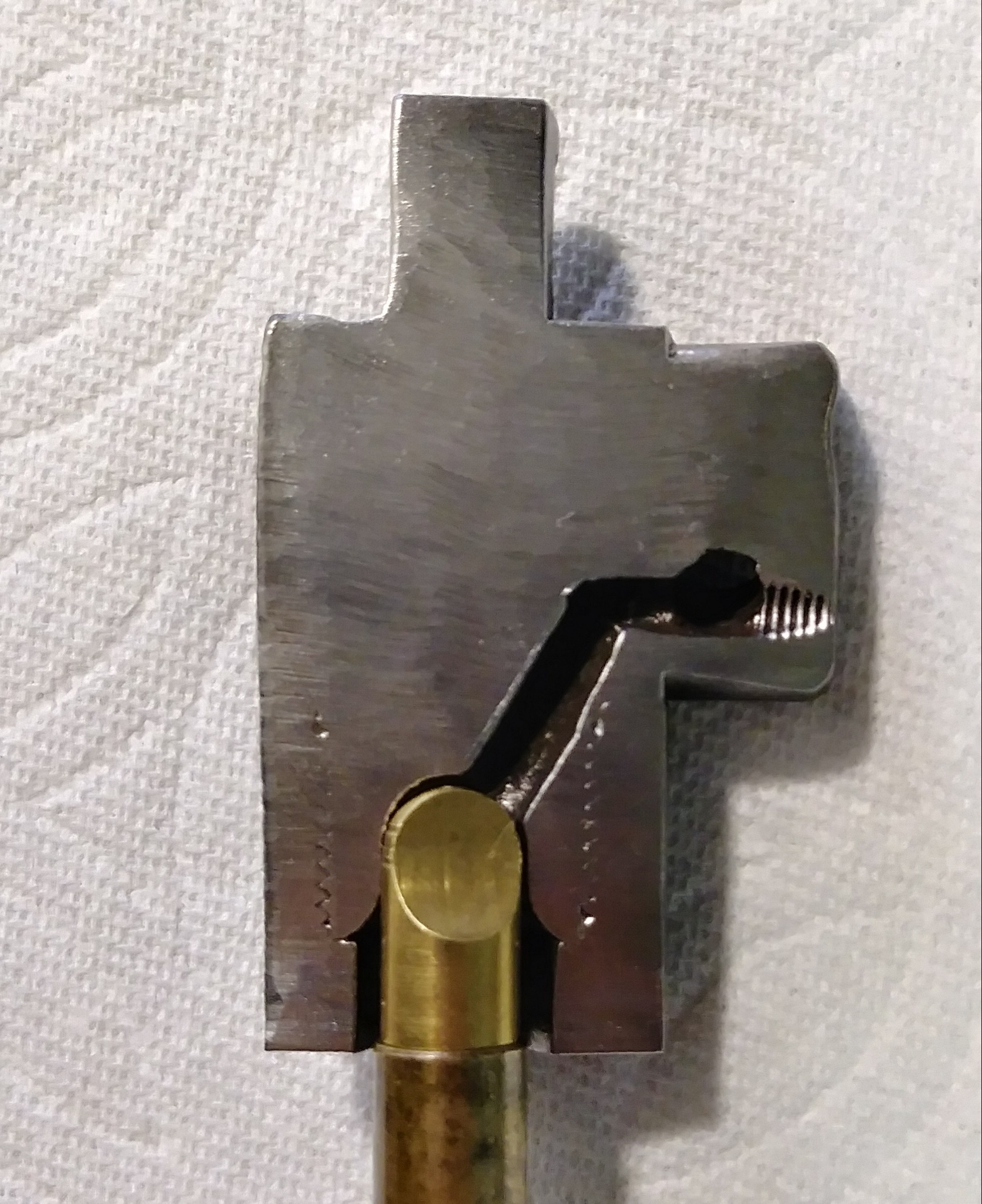

I decided to use this old Roached out .50 Cal Renegade barrel for educational purposes, I thought of sending it to Hoyt for a Rebore, Maybe Relined? But decided against it, This Barrel actually shot well, But had to many things going against it, it was drilled and Tapped for See Through scope mounts, 3-4” of the Bore down at the Breech end was in HORRIBLE condition. I completely stripped the barrel of it’s parts and used them on a REALLY nice old .54 Cal Renegade barrel i had tucked under the Bed  I didn’t buy this Rifle for the barrel (I suspected it would be junk) i bought it for the Stock and accessories for a Brand New Green Mountain LRH Barrel in .54 Cal (Affectionately known as my “White Wale” Barrel

I didn’t buy this Rifle for the barrel (I suspected it would be junk) i bought it for the Stock and accessories for a Brand New Green Mountain LRH Barrel in .54 Cal (Affectionately known as my “White Wale” Barrel  ) Which i now have fitted in this Stock and ready for a test Run :yeah:

) Which i now have fitted in this Stock and ready for a test Run :yeah:

The Reason this old .50 Cal barrel shot decent is the riflings were good from the Crown, down about 20” or so, In other words The bullet had a NASTY 3-4” To get through upon Take off, and then the Riflings were good to the Crown. Cleaning this thing would have continued to be a Nightmare, Just not worth the Hassle

The Reason this old .50 Cal barrel shot decent is the riflings were good from the Crown, down about 20” or so, In other words The bullet had a NASTY 3-4” To get through upon Take off, and then the Riflings were good to the Crown. Cleaning this thing would have continued to be a Nightmare, Just not worth the Hassle