- Joined

- May 19, 2005

- Messages

- 9,205

- Reaction score

- 1,736

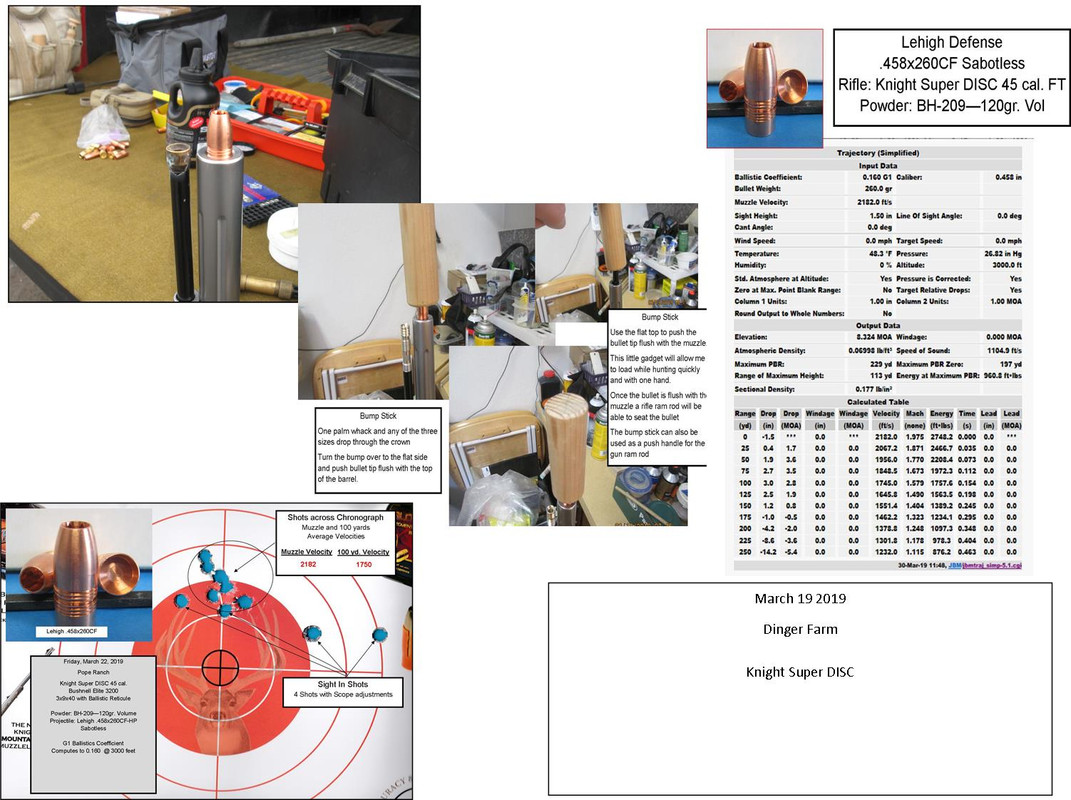

Got out today and once a week or so ago to do more testing of this new bullet from Lehigh. As stated the bullet is labeled .458 as it is truly built for 45-70 barrels that have been converted to a muzzleloading barrel.

At .458 it is somewhat difficult to get through the crown of the regular 45 cal. muzzleloader, but once through the crown it loads very well. I have chosen to size the barbs on the bullets to .454 allowing it to pass through the crown of regular ML bore easier.

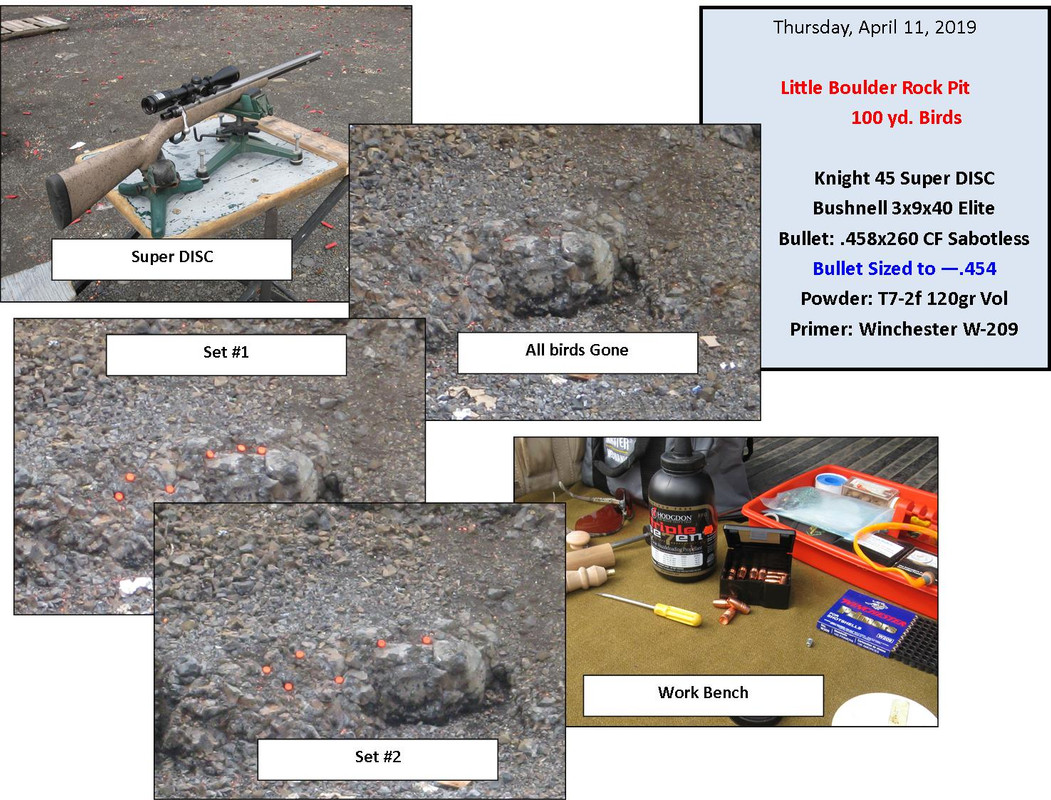

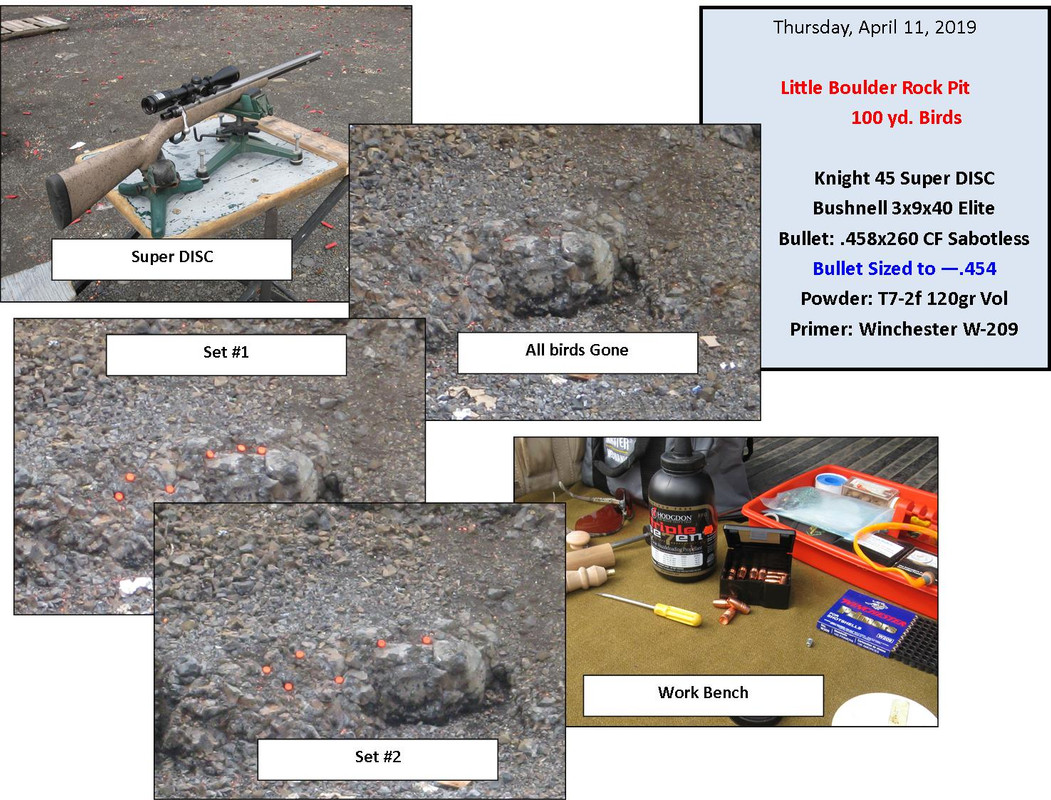

I have really good luck shooting this bullet and really good groups! But, all my testing has been done with BH-209 powder. The test today was to see if I could get similar results using T7 powder, which I normally use. It is just so much less expensive to shoot. Plus in Idaho where I am required to use cap ignition during ML season, I was really interested if T7 would get the job done.

Today proved T7 works just fine! but it needs to be noted the bullet needs to be loaded in a dry barrel!

This picture shows the result of today's run to the Rock Pit.

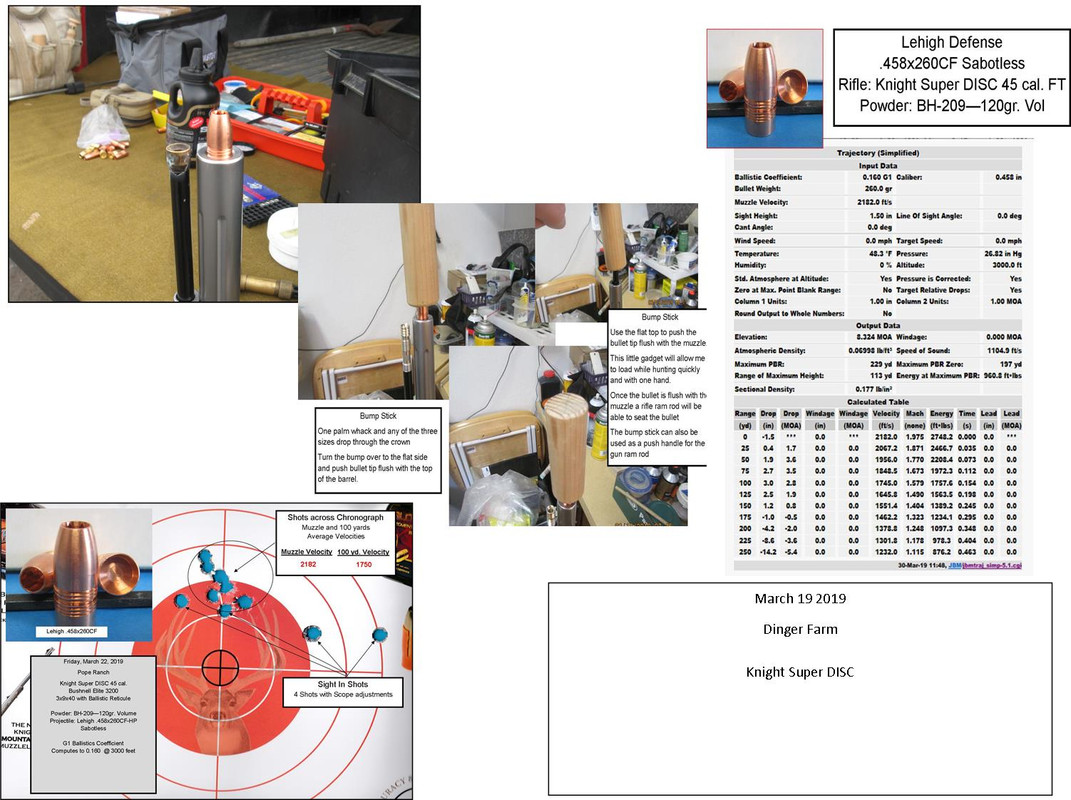

Back in March I did another test shoot trying to compute the BC of the bullet and completing a Ballistic Chart for the bullet. I will tell you the group shot could have been tighter and would have been tighter if I was not so concerned about shooting through two chronographs especially the one at 100 yards. It would be a real pain if I were to shoot one of the chronographs.

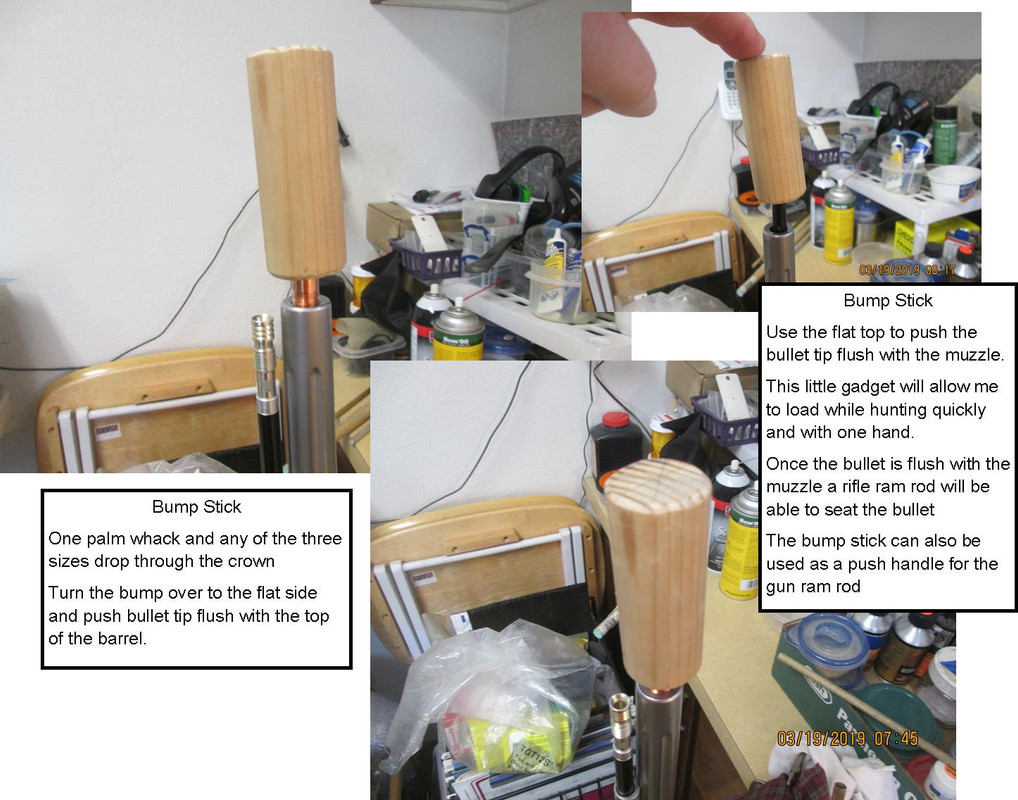

I also developed a 'Bump Stick' to help me get the bullet through the crown and started down the bore.

The rains came again this afternoon and cut the shoot short, but I got what I needed done - would have just liked to have shot a little more.

At .458 it is somewhat difficult to get through the crown of the regular 45 cal. muzzleloader, but once through the crown it loads very well. I have chosen to size the barbs on the bullets to .454 allowing it to pass through the crown of regular ML bore easier.

I have really good luck shooting this bullet and really good groups! But, all my testing has been done with BH-209 powder. The test today was to see if I could get similar results using T7 powder, which I normally use. It is just so much less expensive to shoot. Plus in Idaho where I am required to use cap ignition during ML season, I was really interested if T7 would get the job done.

Today proved T7 works just fine! but it needs to be noted the bullet needs to be loaded in a dry barrel!

This picture shows the result of today's run to the Rock Pit.

Back in March I did another test shoot trying to compute the BC of the bullet and completing a Ballistic Chart for the bullet. I will tell you the group shot could have been tighter and would have been tighter if I was not so concerned about shooting through two chronographs especially the one at 100 yards. It would be a real pain if I were to shoot one of the chronographs.

I also developed a 'Bump Stick' to help me get the bullet through the crown and started down the bore.

The rains came again this afternoon and cut the shoot short, but I got what I needed done - would have just liked to have shot a little more.

Last edited: