- Joined

- Oct 7, 2010

- Messages

- 188

- Reaction score

- 69

what is the best way to clean a breech plug on a knight extreme witn the improved Disc Bare plug.Cleaner drain through it but I cannot see light trough it.

what is the best way to clean a breech plug on a knight extreme witn the improved Disc Bare plug.Cleaner drain through it but I cannot see light trough it.

![Long-BP-Cleaner[2].jpg Long-BP-Cleaner[2].jpg](https://cdn2.imagearchive.com/modernmuzzleloader/data/attachments/9/9948-7a210077591b43b98815b01ea6362f21.jpg)

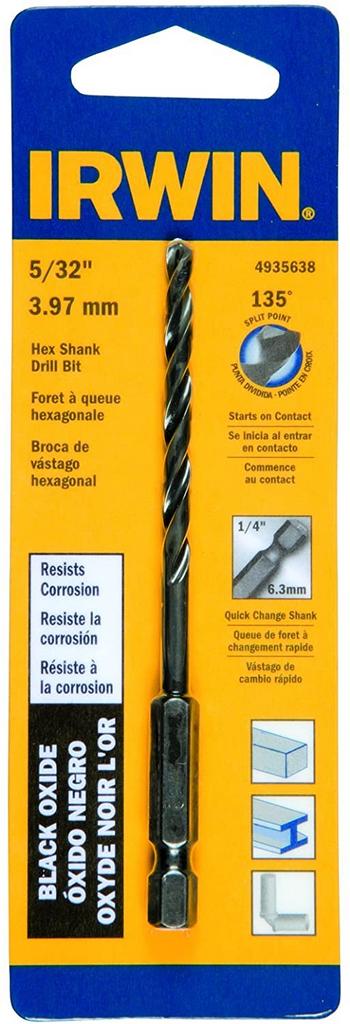

This just made me think, if a well polished bore doesnt foul as badly, wouldn't really polishing up the flame channel also help decrease fouling/carbon buildup in it? Like a miniature Lee Shavers treatment for the breechplug.This ProShot port brush set comes in handy too. Use it after using a bit just to shine up the channel and clean the vent liner threads. The larger of the 2 brushes does a good job cleaning up anything you cant get out with a bit. A .243/6mm or 25cal bore brush fits the primer pocket IIRC but not really needed.

This just made me think, if a well polished bore doesnt foul as badly, wouldn't really polishing up the flame channel also help decrease fouling/carbon buildup in it?

making some special bullet lube.

No im going with his Stihl HD oil and nasa lubeDid you get a skunk or pick up a car kill? Or aren't you using Lewis's skunk fat recipe? lol

Enter your email address to join: