When I was at the Oakridge shoot ,a shooter on my sguad looked at the bullets I was shooting and showed my brother who was there helping me on my first shoot that a lot of my bullet bases were bad. I had bought these at Barco. Now where can one buy other bullets? Also I plan to cast my own when I find a good combination for my gun. I also noted that paper patch shooters out number the grease groove bullets. They may have been swaged bullets . I really think I whant to go to paper patch in fear of leading my barrel or am I just or am I just over worry. Still waiting on my lock repair from Rod, but whant to ready for load testing the day I get it back. Thanks .

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Buying vrs. Casting bullets

- Thread starter wildcat2

- Start date

Help Support Modern Muzzleloading Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Idaholewis

Well-Known Member

- Joined

- Jun 30, 2017

- Messages

- 7,287

- Reaction score

- 10,288

Which bullets were shooting? When you say Barco did you mean BACO as in Buffalo Arms Co.? I have been shooting their bullets for a few years now, The only bullets from BACO that i have experience with is their Cupped Base Paper Patch bullets, They are a Swaged bullet, I have weighed MANY of them and they are extremely close, I have yet to see 1 more than a 1/2 Grain Different, 99% are within a 10th or 2 of eachother. The only complaint i have is the sharp base edge from the Swaging process, if you wrap your paper and run them through a ‘Finish’ sizer, You will likely cut the paper at the base

Like this

My fix for this is to very slightly deburr the bases (no force needed! Just very lightly turn) i stand them straight up with bases sitting flat on a sheet of fine emory cloth, i make about a half turn, Then a very gentle turn using my RCBS case neck deburring tool around the base edge. Again i am NOT changing the base, just ever so slightly bumping the knife sharp edge off the base to keep from cutting my papers. I am shooting these bullets very accurately out to 500 yards with my TC Hawken Sidelock, .45 Cal Green Mountain LRH 1:30 twist barrel, Tang mounted peep, Lyman 17 series Globe front sight, and using Lee Shavers BPCR inserts.

If you are shooting Grease Groove Cast bullets from them i have no experience with them at all.

Like this

My fix for this is to very slightly deburr the bases (no force needed! Just very lightly turn) i stand them straight up with bases sitting flat on a sheet of fine emory cloth, i make about a half turn, Then a very gentle turn using my RCBS case neck deburring tool around the base edge. Again i am NOT changing the base, just ever so slightly bumping the knife sharp edge off the base to keep from cutting my papers. I am shooting these bullets very accurately out to 500 yards with my TC Hawken Sidelock, .45 Cal Green Mountain LRH 1:30 twist barrel, Tang mounted peep, Lyman 17 series Globe front sight, and using Lee Shavers BPCR inserts.

If you are shooting Grease Groove Cast bullets from them i have no experience with them at all.

Yes I ment BACO. I have some swaged bullets from them ,500 gr. .444,two wraps of their paper. And they come out atb.450 just right for my barrel. Have not trye'd them yet ,will be the first ones to roll out the muzzle when I get my lock back.

Idaholewis

Well-Known Member

- Joined

- Jun 30, 2017

- Messages

- 7,287

- Reaction score

- 10,288

wildcat2 said:Yes I ment BACO. I have some swaged bullets from them ,500 gr. .444,two wraps of their paper. And they come out atb.450 just right for my barrel. Have not trye'd them yet ,will be the first ones to roll out the muzzle when I get my lock back.

I have had really good luck with their Paper Patch bullets, The ones in the photo above are .444 Diameter 400 Grain, My 1:30 Twist Hawken loves em! :yeah:

I know BACO sells Grease Groove bullets already lubed with SPG, but i have never even looked at them? Back when i started building my Fast 1:18 Twist Long Range Renegade i asked Lee Shavers opinion on a Good mold to get me out to 1,000 yards? I told him i was looking at the Elliptical designs in PP, And GG, Lee told me to pay VERY CLOSE attention to the bases, regardless of the of the design. Make sure those bases are perfect, nice n sharp :yeah: I ended up buying both BACO Molds, .453 Diameter 530 Grain GG, And a .443 Diameter .530 Grain PP, So far my Rifle favors the GG

What is your bore size? Mine is 450 and I hade some 451 /530 gr. GG that I had to size them in my 450 Lee die I had made up.I should of asked more precise questions to the man on my squad, but I was to imtiminated with being very green and new. Not to mention my lock trouble. So much to learn ,but I can not wait for the shoot again next year. Hope to burn a lot of powder this summer to be a better competitive shooter. Hope the feed I get off this forum will aid in this also. Thanks everyone.

Idaholewis

Well-Known Member

- Joined

- Jun 30, 2017

- Messages

- 7,287

- Reaction score

- 10,288

wildcat2 said:What is your bore size? Mine is 450 and I hade some 451 /530 gr. GG that I had to size them in my 450 Lee die I had made up.I should of asked more precise questions to the man on my squad, but I was to imtiminated with being very green and new. Not to mention my lock trouble. So much to learn ,but I can not wait for the shoot again next year. Hope to burn a lot of powder this summer to be a better competitive shooter. Hope the feed I get off this forum will aid in this also. Thanks everyone.

I have 2 .45 Cal fast twist Sidelocks, Both are 1” Green Mountain barrels, 1 is a 28” 1:30 Twist that i have in a 1” TC Hawken stock, and the other is a 32” 1:18 Twist that i Have in a TC Renegade Stock. The 1:30 Twist is a .451 Bore, and 1:18 Twist is a .452 Bore. I have the 1:18 setup to go Really Long Range, I am stil playing with load development on that rifle, it seems to like the .453 BACO GG bullet the best so far, i am lubing the bullets and running them through a Lee .451.75-.452 Sizer, they just ‘Kiss’ the Bore walls on loading. I to have a LOT of learning to do

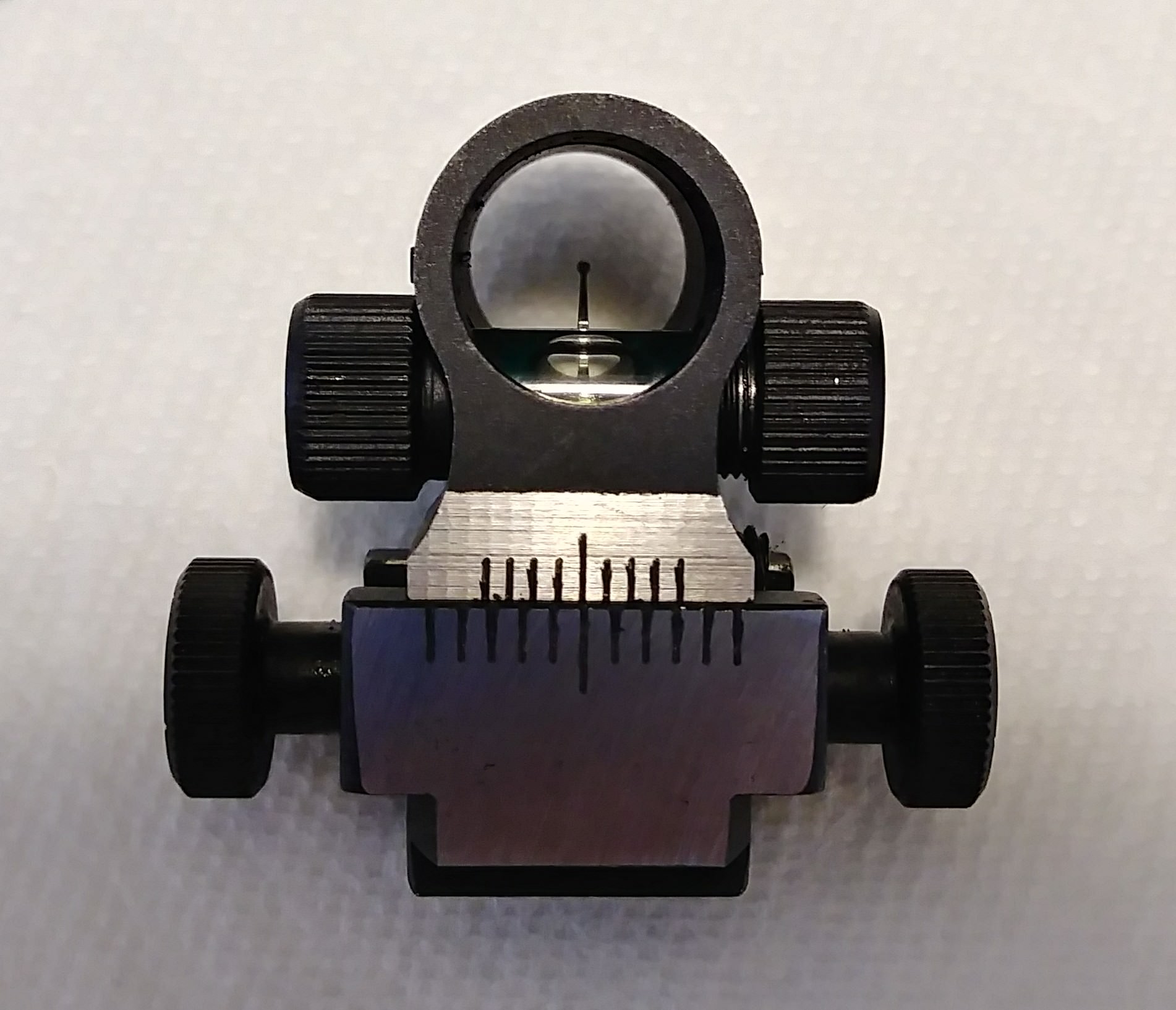

Here is my Tang peep setup on my 1:18, and the Front sight i am using. The Tang Peep is a Lee Shaver Super Grade, and the Front Globe is Lee’s adjustable Ferris Creedmoor sight

And the adjustable Front sight

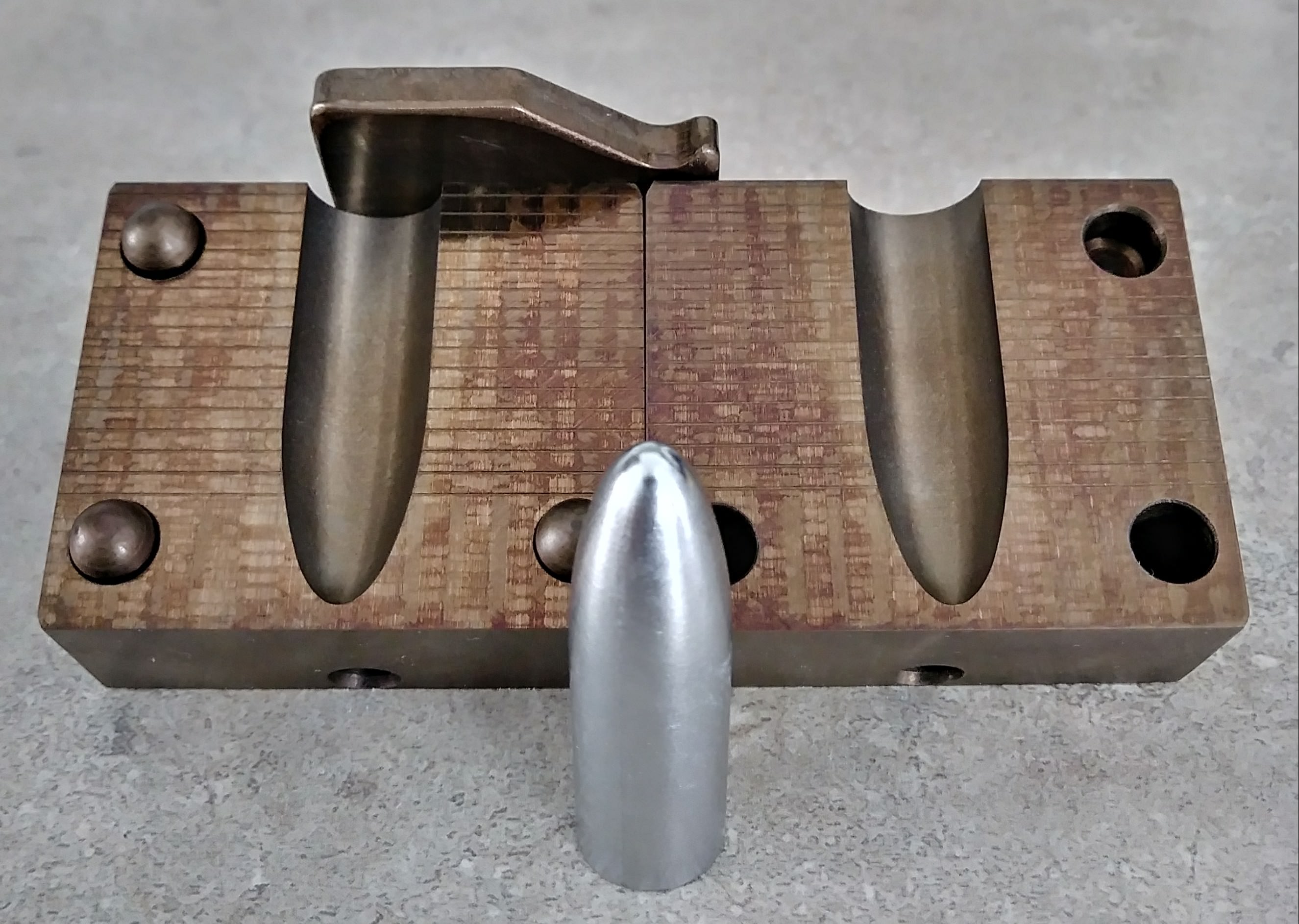

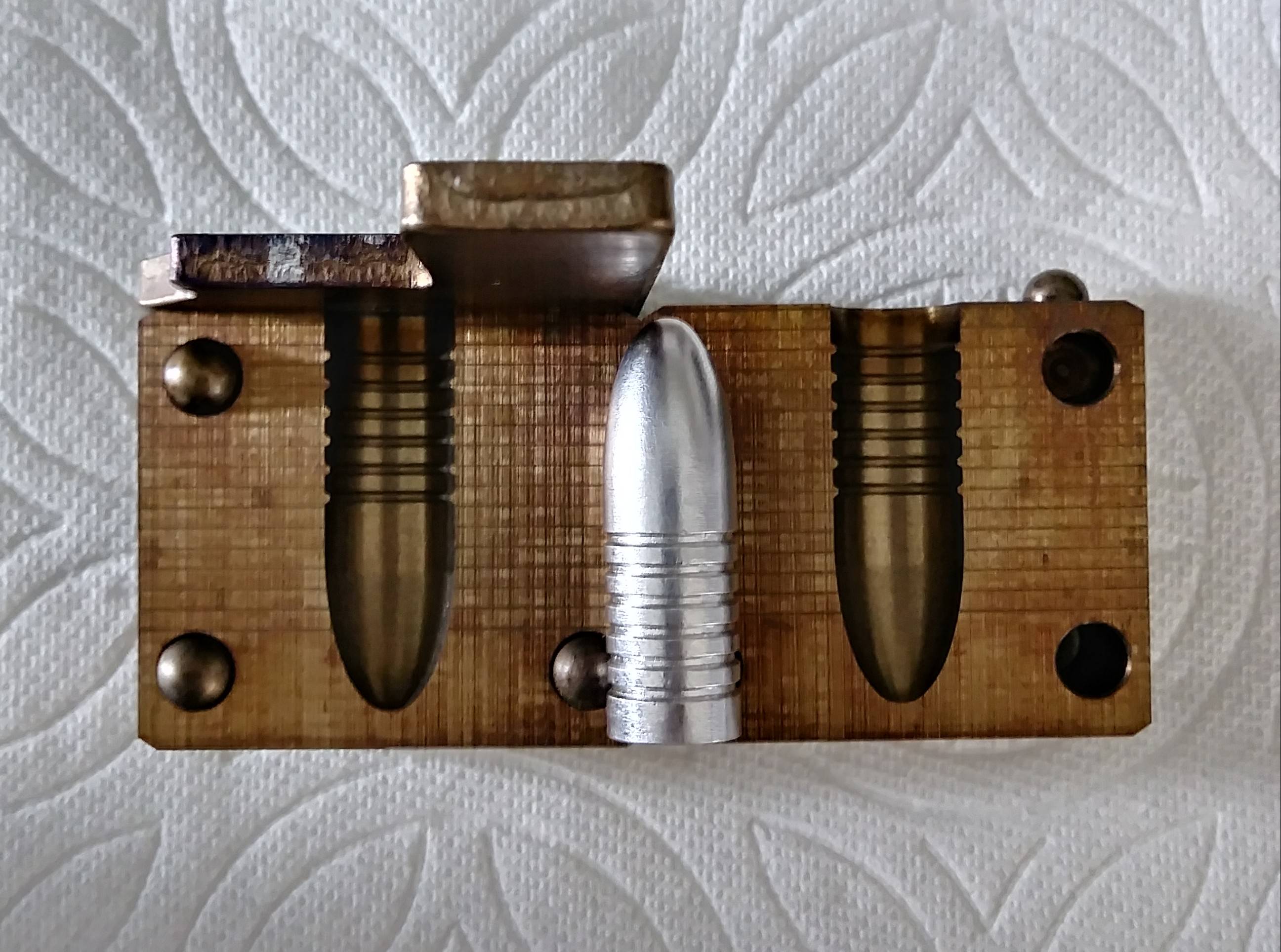

The Molds i am using, Both BACO

Idaholewis

Well-Known Member

- Joined

- Jun 30, 2017

- Messages

- 7,287

- Reaction score

- 10,288

wildcat2 said:Nice bullets out of those moulds.Do you pan lube? Are they pure lead?

I haven’t pan lubed these of yet, i am usually only doing about 10 or so at a time for testing loads, I find it just as easy to lube them by hand and then run them through my .452 Lee push through Sizer, The end result is a perfectly lubed and sized bullet. If i were gonna do a bunch at 1 time then i would definitely Pan Lube. The Big GG bullet above drops at a true .453 Which works perfectly to run through my .452, You feel no resistance, it is just barely doing anything, But fit to my bore is perfect. These are not pure lead, they are 20:1, I am experimenting with 30:1 For these Elliptical nose bullets, Most of the BPCR Guy’s seem to Favor 20:1, and 30:1 Alloys. 20:1 is pretty darn hard stuff at 10 Brinell (BHN) the 30:1 is a little softer at 9 BHN

What is your hand lube mixture.? I take it you just smear it on then size. We're your sizer in the tenths of a thousand? My bore is 450 or a hair larger. But if I was to take my gun out on a hunt I would like to have a tighter fitting bullet so I would not have to worry of the bullet coming off the charge and possibly ringing my barrel.

Idaholewis

Well-Known Member

- Joined

- Jun 30, 2017

- Messages

- 7,287

- Reaction score

- 10,288

wildcat2 said:What is your hand lube mixture.? I take it you just smear it on then size. We're your sizer in the tenths of a thousand? My bore is 450 or a hair larger. But if I was to take my gun out on a hunt I would like to have a tighter fitting bullet so I would not have to worry of the bullet coming off the charge and possibly ringing my barrel.

The lube i am currently using is a recipe from Forum member edmehlig, it is in the Casting section under bullet lube recipes, “Blue .451 Lube” I really like it! I thinned it down a tiny bit with a Bear grease mixture i have since i shoot a lot in cold weather, Otherwise it would be perfect the way it is. Another lube i have tried that i really liked is from Bullshop, it's called NASA, REALLY good stuff! I think Ed’s Blue .451 and the Bullshop NASA stuff are very comparable. Bullet lube can DEFINITELY make a difference in accuracy, in my experience a thinner “tacky” lube has been best, Before trying the Bullshop NASA stuff and Ed’s Blue .451, i was using a much stiffer lube called Gatfeo no. 1 i had got from a friend, Accuracy wasn’t horrible, but never was really great either? I was talking to Dan of Bullshop about a particular bullet and accuracy issues i was having, i sent him a picture of my lubed bullets (a copy of 1 of His bullets) And the target i had shot, The very first thing Dan noticed and asked about was my Lube? It was the Gatfeo stuff, Dan told me that lube can play a LARGE part in accuracy, After some experimenting I absolutely agree with him!! The other thing i have found that made a BIG difference in accuracy is the Over Powder Wad.

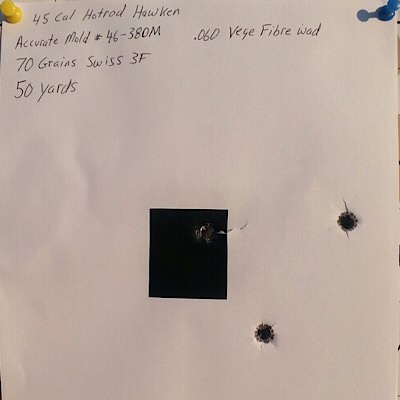

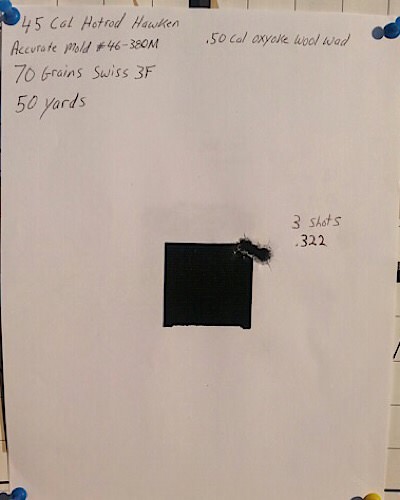

Here is a good example of what i found with OP wads, these 2 targets were shot identical in everyway EXCEPT the OP wads. In my testing with Greased bullets Wool has outperformed hard card type OP wads hands down, I don’t even bother with Hard Card Wads and Lubed bullets anymore.

.060 Vege Fibre (hard card)

And here is with Wool

Idaholewis

Well-Known Member

- Joined

- Jun 30, 2017

- Messages

- 7,287

- Reaction score

- 10,288

wildcat2 said:What is your hand lube mixture.? I take it you just smear it on then size. We're your sizer in the tenths of a thousand? My bore is 450 or a hair larger. But if I was to take my gun out on a hunt I would like to have a tighter fitting bullet so I would not have to worry of the bullet coming off the charge and possibly ringing my barrel.

When i plan to test a group and hand lube the few bullets, all i do is smear it in the grooves the best i can, i shoot for a little more lube than needed, I use a pair of rubber gloves and roll the bullets back n forth through my gloved hands, Then push them through my sizer, any excess is removed perfectly once they go through the sizer. When i speak of Sizers and sizes of say a Half, and 3/4, i am referring to Lee push through sizers, it is EXTREMELY rare that you get a Lee sizer that is dead on what it says, Example, I recently bought a .452, and it is actually closer to .453, Almost every Lee sizer i have bought has been off slightly, to quite a bit.

The best way to remedy this if you have 1 particular bore you are working with is to buy a Lee push through sizer that is .001 smaller than you need, It might end up being a perfect fit? But if not, at least it should be to small and you can slightly open it to achieve a PERFECT fit for that particular bore. I have done this a BUNCH and it works great! :yeah: I use a solid piece of 3/8 Round steel stock about 10-12 inches long, wrap a piece of fine grit sandpaper around the steel rod and tape the ends, remove the lock nut on the die, ad some fine oil to the sandpaper and slide the 3/8 round steel stock wrapped with sandpaper through the die, hold each end of the rod and roll back n forth allowing the die to roll on a Flat smooth surface, slightly turn the steel rod to expose a new sandpaper surface if needed. If you are only removing .001 use a VERY fine grit paper like 1200 Grit, Go for 30 seconds or so, clean the die, and check by running a bullet through, check that bullet to the Bore you are working with, if done correctly you can easily obtain the “Perfect” fit to that particular bore. My advice is to go SLOW, and check often!! You can always remove more material, but you can’t add any back, i happen to know this first hand

I ABSOLUTELY agree with you on a snugger fitting bullet for hunting, For target work i want my bullet to just “kiss” the bore walls all the way down, just snug enough to hold, they load easily. For hunting i want my bullet to fit tighter, I want noticeable resistance from start to finish to insure that the Bullet can NOT budge off the powder. I have achieved both in all of my rifles by playing with sizer dies. The more guns you have, the more complicated/confusing it gets

ARe: Buying vrs. Casting bullets

OK thanks, I have a 449 lee push threw die that I plan to do that. I will put it in my wood lathe and some fine paper or honing polish to do this. Do you use the wool under your swaged and gg bullets? I saw several guys using wool at the shoot. I have some and plan to try. The rag paper they talk about is gone ,so I bought the paper from BACO to wrap with.got some paper from my brother that he uses to build his RC planes with.tuff stuff ,going to try it.also.on my 444 swaged bullets.When I get my gun back together.

OK thanks, I have a 449 lee push threw die that I plan to do that. I will put it in my wood lathe and some fine paper or honing polish to do this. Do you use the wool under your swaged and gg bullets? I saw several guys using wool at the shoot. I have some and plan to try. The rag paper they talk about is gone ,so I bought the paper from BACO to wrap with.got some paper from my brother that he uses to build his RC planes with.tuff stuff ,going to try it.also.on my 444 swaged bullets.When I get my gun back together.

Idaholewis

Well-Known Member

- Joined

- Jun 30, 2017

- Messages

- 7,287

- Reaction score

- 10,288

Re: ARe: Buying vrs. Casting bullets

In general i use the Card type (.060 Vege Fibre) with the Swaged cupped base PP bullets i get from BACO, I have never had any Swaged Grease Groove bullets, but if i did i would definitely try both materials, but I would bank on the Wool OP wads performing better. My theory on the Hard Card Wads and Grease Groove Bullets is the Card is sticking to the bullet base from lube/melting lube, i think they are hanging on to bullet base for a ways upon exiting the bore before finally separating, and since the bullet base is what Steers the bullet, if this is actually happening? It could very well cause the bullet to steer wrong before the wad seperates? It’s the only thing that makes good sense to me? I have never shot real good groups With GG bullets and Card type Wads, Wool has ALWAYS been my best performer with GG bullets. With my PP bullets i cant really tell a difference between Wool, and Hard Card? They seem to perform equally well, at least in my testing. This is why i always say if I could only choose 1 OP Wad material it would definitely be Wool. And i prefer the 1/8” stuff, I usually buy the Oxyoke brand already punched out, and lubed. If you shoot a BUNCH I believe it would be better to buy Wool felt from Durofelt online and punch your own. I traded a forum member some bullets for some bulk Durofelt, it is REALLY good looking stuff!

I have 2 different brands of the old 25% cotton 9# onion skin paper i traded a friend in Utah (the 25% cotton stuff is considered Vintage these days) Both brands of my paper are the same thickness, and ad between 7-8 Thou to the overal Diameter after 2 wraps. I have tested the stuff you get Now days (Wood Fiber) The Paper Mill store online sells it for 25 bucks a 500 sheet Ream, I can’t be positive, but I believe this is the stuff BACO sells? I need to get a few sheets from them and see if it’s the same? I live about 30 minutes or so from BACO and am a Regular Customer there The stuff i tested came from a forum member friend that had bought a Ream from the Paper Mill store, It is a tiny bit thinner than my old stuff, It performed VERY well, one difference I noticed immediately is how “Slick” the wood fiber stuff is, it is REALLY slick stuff! I wrapped and loaded a hunting bullet, S&W 500 type bullet that i shoot in my Stainless .50 Cal 1:28 fast twist, I was headed out to the local sandpit to test the Paper, and shoot a Group. I always load my rifle at home, and use it as a Fouler shot when i get to the pit. I got setup to shoot, i used my Range rod to make sure the bullet had not slid on my out to the Pit, I didn’t witness mark my Range Rod after i loaded the Rifle so This is TOTALLY my fault, I just slid the Range Rod down the bore gently (knowing if the bullet had slid i would feel it, and Re seat it) I Bottomed the Rod out and gave a decent push, I capped the rifle and fired it, No recoil? It obviously Sounded odd? And the puff of smoke was different. I immediately grabbed my gun case and checked, SURE enough there was the naked bullet laying in the bottom of my Gun case! The bullet had slid out of the paper jacket on my 2 mile drive to the local Sand pit. Talk about messing with your confidence just before hunting season!! When i wrapped this bullet I didn’t bother running it through my “Finish” sizer (.500) As the paper was slightly thinner than my old 25% Cotton stuff (My old paper has what is called a Cockle texture to it) my old Paper has always held the bullet good n snug. When i loaded my rifle that morning it felt fine, it didn’t just slide down the bore with the Range Rod weight alone, i used my thumb and index finger to help it along, it wasn’t tight by any means, but also wasn’t loose, it felt perfect to me? But that Darn bullet stil slid out of the Paper jacket! I have NEVER had this happen with my old 25% Cotton Cockle texture paper

The stuff i tested came from a forum member friend that had bought a Ream from the Paper Mill store, It is a tiny bit thinner than my old stuff, It performed VERY well, one difference I noticed immediately is how “Slick” the wood fiber stuff is, it is REALLY slick stuff! I wrapped and loaded a hunting bullet, S&W 500 type bullet that i shoot in my Stainless .50 Cal 1:28 fast twist, I was headed out to the local sandpit to test the Paper, and shoot a Group. I always load my rifle at home, and use it as a Fouler shot when i get to the pit. I got setup to shoot, i used my Range rod to make sure the bullet had not slid on my out to the Pit, I didn’t witness mark my Range Rod after i loaded the Rifle so This is TOTALLY my fault, I just slid the Range Rod down the bore gently (knowing if the bullet had slid i would feel it, and Re seat it) I Bottomed the Rod out and gave a decent push, I capped the rifle and fired it, No recoil? It obviously Sounded odd? And the puff of smoke was different. I immediately grabbed my gun case and checked, SURE enough there was the naked bullet laying in the bottom of my Gun case! The bullet had slid out of the paper jacket on my 2 mile drive to the local Sand pit. Talk about messing with your confidence just before hunting season!! When i wrapped this bullet I didn’t bother running it through my “Finish” sizer (.500) As the paper was slightly thinner than my old 25% Cotton stuff (My old paper has what is called a Cockle texture to it) my old Paper has always held the bullet good n snug. When i loaded my rifle that morning it felt fine, it didn’t just slide down the bore with the Range Rod weight alone, i used my thumb and index finger to help it along, it wasn’t tight by any means, but also wasn’t loose, it felt perfect to me? But that Darn bullet stil slid out of the Paper jacket! I have NEVER had this happen with my old 25% Cotton Cockle texture paper

I worked on a solution to this for hunting purposes, i had to in order to gather the confidence to hunt with my PP bullets and this New paper.

Here is what i did, and it has worked Flawlessly for me, No change in my Cold bore, Group, etc.

The procedure above tightened my bullets up GOOD N TIGHT, and gave me the Confidence i needed to hunt with my PP bullets

wildcat2 said:OK thanks, I have a 449 lee push threw die that I plan to do that. I will put it in my wood lathe and some fine paper or honing polish to do this. Do you use the wool under your swaged and gg bullets? I saw several guys using wool at the shoot. I have some and plan to try. The rag paper they talk about is gone ,so I bought the paper from BACO to wrap with.got some paper from my brother that he uses to build his RC planes with.tuff stuff ,going to try it.also.on my 444 swaged bullets.When I get my gun back together.

In general i use the Card type (.060 Vege Fibre) with the Swaged cupped base PP bullets i get from BACO, I have never had any Swaged Grease Groove bullets, but if i did i would definitely try both materials, but I would bank on the Wool OP wads performing better. My theory on the Hard Card Wads and Grease Groove Bullets is the Card is sticking to the bullet base from lube/melting lube, i think they are hanging on to bullet base for a ways upon exiting the bore before finally separating, and since the bullet base is what Steers the bullet, if this is actually happening? It could very well cause the bullet to steer wrong before the wad seperates? It’s the only thing that makes good sense to me? I have never shot real good groups With GG bullets and Card type Wads, Wool has ALWAYS been my best performer with GG bullets. With my PP bullets i cant really tell a difference between Wool, and Hard Card? They seem to perform equally well, at least in my testing. This is why i always say if I could only choose 1 OP Wad material it would definitely be Wool. And i prefer the 1/8” stuff, I usually buy the Oxyoke brand already punched out, and lubed. If you shoot a BUNCH I believe it would be better to buy Wool felt from Durofelt online and punch your own. I traded a forum member some bullets for some bulk Durofelt, it is REALLY good looking stuff!

I have 2 different brands of the old 25% cotton 9# onion skin paper i traded a friend in Utah (the 25% cotton stuff is considered Vintage these days) Both brands of my paper are the same thickness, and ad between 7-8 Thou to the overal Diameter after 2 wraps. I have tested the stuff you get Now days (Wood Fiber) The Paper Mill store online sells it for 25 bucks a 500 sheet Ream, I can’t be positive, but I believe this is the stuff BACO sells? I need to get a few sheets from them and see if it’s the same? I live about 30 minutes or so from BACO and am a Regular Customer there

I worked on a solution to this for hunting purposes, i had to in order to gather the confidence to hunt with my PP bullets and this New paper.

Here is what i did, and it has worked Flawlessly for me, No change in my Cold bore, Group, etc.

The procedure above tightened my bullets up GOOD N TIGHT, and gave me the Confidence i needed to hunt with my PP bullets

Idaholewis

Well-Known Member

- Joined

- Jun 30, 2017

- Messages

- 7,287

- Reaction score

- 10,288

Had the above method not worked (The paper strip i did to tighten my bullet up for hunting purposes) my next step was going to be Rolling a Group of bullets GENTLY between 2 Mill files to give them a slight texture in hopes that it would hold them securely in the Paper jacket. I stil plan to try it, Just haven’t got around to it.

Idaholewis

Well-Known Member

- Joined

- Jun 30, 2017

- Messages

- 7,287

- Reaction score

- 10,288

wildcat2 said:I did roll my 450 bullets with a file and it did snug it up nicely, but my gun builder told me it would not be consistent for match shooting. Also I don't think there is such a bullet of the gg swaged.

That makes good sense, Rolling them between 2 files would be difficult to impossible to get them all identical.

I don’t think so either on the Swaged GG? I have never seen a Swaged GG bullet listed on BACO’s Site. I don’t know if anyone Swages a GG, or if its even possible? My only experience is with BACO’s Swaged cupped base PP bullets, They are Swaged from lead Wire

Just curious on loading with wads. You dump your powder, put your wad in and seat it then start and seat your bullet? I have never used a wad with a muzzleloader . I use 2 wads with a grease cookie in between with my BPCR PP hunting loads . Do you think your wool wads are more accurate because they are lubed vs the dry veggie wad? Do you think the lubed wads effect the powder charge any? Thanks Mike.

Idaholewis

Well-Known Member

- Joined

- Jun 30, 2017

- Messages

- 7,287

- Reaction score

- 10,288

MSalyards said:Just curious on loading with wads. You dump your powder, put your wad in and seat it then start and seat your bullet? I have never used a wad with a muzzleloader . I use 2 wads with a grease cookie in between with my BPCR PP hunting loads . Do you think your wool wads are more accurate because they are lubed vs the dry veggie wad? Do you think the lubed wads effect the powder charge any? Thanks Mike.

Yes, I dump my powder charge in, Tap the buttstock to make sure powder settles in the snail/under the nipple (Sidelock) Start wad and seat it firmly on the powder, Then seat my bullet.

I cannot say for sure if the Lubed Wool wad is giving me better accuracy vs the Dry veggie wads? I have never tried lubing the Veggie Wads and testing to see? My belief is the Veggie Wad is sticking to the bullet base from the melting lube of the bullet as it is traveling up the bore? I can not prove this, it is just a theory of mine? I have shot a BUNCH between the Veggie and Wool OP Wads with Grease Groove bullets and in my experience Wool has ALWAYS gave me the best results. I believe the extra surface/thickness of the Wool Wad allows it to ‘Suck up’ the melting lube, yet seperate easily upon exiting the bore, leaving the bullet alone to tend to business. Again, this is my theory? Now Paper Patch bullets on the other hand don’t seem affected by Wad type in my experience, i have shot Hard Card (Vege Fibre, Nitro Cards) And Wool equally well with my PP bullets. Grease Groove is where I Notice the difference in OP wads

The Wool Wads i buy are Oxyoke brand, They say Lubed, They look Dry to me? I have squeezed them between my thumb and index finger, you can see a VERY SLIGHT sign of oil, and sometimes nothing at all? Whatever it is they use is some really thin stuff, and not much of it, I suspect something like Olive oil, Maybe mineral oil? Here Again, I cannot say if it effects the powder or not? I have shot over snow a LOT and i have never seen any unburned powder on top, And i actually look for it. I will be Punching my own Wool Wads soon from Bulk Material I recieved from a Forum member, I plan to use them Dry and see if i can tell any difference in accuracy? I will test this with proven load/Rifle Combos

That will be a neat experiment, let me know the results. Also have you tried the same bullet wadless? Bill Bagwell was the exhibition shooter for Goex powder for many years. He have me several different cartridge loads with grease groove bullets and told me that if shooting right away or in cold weather (he lives in Texas) not to bother with a wad. He said that if the weather was warmer or it was going to be a while to just use a wax paper wad to keep the lube from migrating into the powder. I do believe that Kenny Wasserburgers 45/110 PP loads do include a felt wad. His success with the felt wads leads me to believe their is something to them. He has many wins in the BPCR crowd including the 5 shot at 200 yd world record. I have never used a felt type wad but now you have me thinking. Thanks Mike.

Similar threads

- Replies

- 4

- Views

- 772