- Joined

- Dec 29, 2007

- Messages

- 4,946

- Reaction score

- 3,106

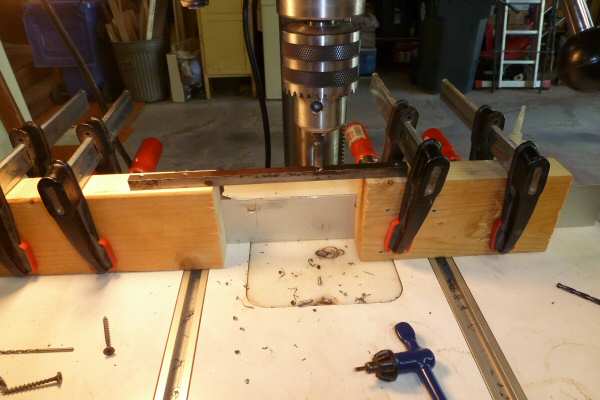

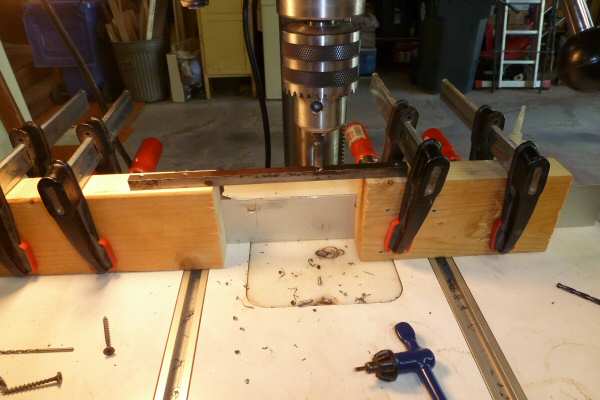

This morning i made eleven vent liner. Wished to go shooting, but it has been raining several days in a row; figured the hills would be quite muddy. To do the job i needed some kinda jig. Wandering around the house and yard i found these piece of steel and wood.

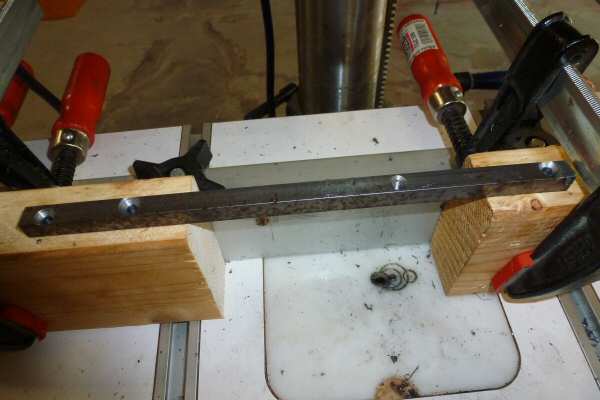

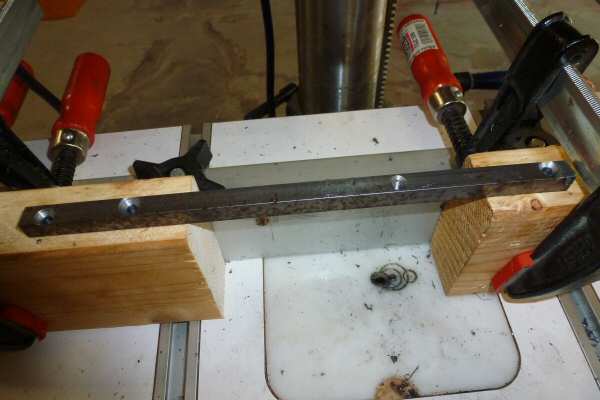

The steel was a short piece of 3/8" square mild steel rod. The piece of 2 x 4 was cut in about half, and holes were drilled through the steel, so it could be fastened to the pieces of two by.

The wood were clamped to the drill press fence, and the rod fastened to the wood. They were positioned so there would be space for my left hand. The rod was drilled through with a 5/32" drill. The hole was countersunk. Then the belts were removed from the drill press, and the hole tapped with 10-32 threads.

Then the screws holding the rod in place were removed. The rod was turned over; the bottom of the tapped hole was countersunk. The purpose of this was so a holo-krome screw could be more easily threaded into the hole from the bottom. Then the rod was put back in place and the screws turned into place, but left loose.

A 5/32" drill was chucked, then lowered into the tapped hole. This positioned the rod, so the screws holding it to the wood could be tightened.

Then a screw was run up from the bottom into the jig. A # 1 center drill was chucked, the end of the screw lubed with mineral oil, and a tapered lead was made into the end of the screw, while holding the screw from spinning with a hex key.

Then the screw was removed from the bottom of the jig, and threaded in on top. The center drill was replaced with a #70 drill, lube applied, and a 0.028" hole drilled through the screw.

After the one vent liner was completed, the #1 center drill was installed into the chuck again, and 10 screws installed in the jig one by one. Each screw was drilled with the center drill so a tapered lead was created into the end.

Then the center drill was removed; the #70 drill chucked, and the 10 screws threaded into the top of the jig one by one, and a 0.028" hole was drilled through each.

The box of 100 screws cost $18. The # 70 cobalt drill cost $3 or so, and is usually good for at least 20 holes. The #1 center drill cost about $2 i think.

The steel was a short piece of 3/8" square mild steel rod. The piece of 2 x 4 was cut in about half, and holes were drilled through the steel, so it could be fastened to the pieces of two by.

The wood were clamped to the drill press fence, and the rod fastened to the wood. They were positioned so there would be space for my left hand. The rod was drilled through with a 5/32" drill. The hole was countersunk. Then the belts were removed from the drill press, and the hole tapped with 10-32 threads.

Then the screws holding the rod in place were removed. The rod was turned over; the bottom of the tapped hole was countersunk. The purpose of this was so a holo-krome screw could be more easily threaded into the hole from the bottom. Then the rod was put back in place and the screws turned into place, but left loose.

A 5/32" drill was chucked, then lowered into the tapped hole. This positioned the rod, so the screws holding it to the wood could be tightened.

Then a screw was run up from the bottom into the jig. A # 1 center drill was chucked, the end of the screw lubed with mineral oil, and a tapered lead was made into the end of the screw, while holding the screw from spinning with a hex key.

Then the screw was removed from the bottom of the jig, and threaded in on top. The center drill was replaced with a #70 drill, lube applied, and a 0.028" hole drilled through the screw.

After the one vent liner was completed, the #1 center drill was installed into the chuck again, and 10 screws installed in the jig one by one. Each screw was drilled with the center drill so a tapered lead was created into the end.

Then the center drill was removed; the #70 drill chucked, and the 10 screws threaded into the top of the jig one by one, and a 0.028" hole was drilled through each.

The box of 100 screws cost $18. The # 70 cobalt drill cost $3 or so, and is usually good for at least 20 holes. The #1 center drill cost about $2 i think.