You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Felt wad over powder

- Thread starter turkey4

- Start date

Help Support Modern Muzzleloading Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

- Joined

- Jan 15, 2016

- Messages

- 3,733

- Reaction score

- 2,992

I’m in the habit of pushing the wad by itself, then pushing the bullet. Either way works, I’m set in my ways and too late to change now.What is the correct way to load them I've seen post on by theirselves or with the conical bullet, I'll be using the no excuse 420 in a vortex Northwest ultralight magnum rifle.

- Joined

- Feb 13, 2020

- Messages

- 1,730

- Reaction score

- 2,226

I push the wad (oversized) down with the lead ,tends to straighten out the wad (no tipping) at least that's what's the target says (most of the time) Ed

- Joined

- May 22, 2005

- Messages

- 3,819

- Reaction score

- 2,128

I'm with HC, load the wad then the conical. Taken lots of deer to change anything now.

Idaholewis

Well-Known Member

- Joined

- Jun 30, 2017

- Messages

- 7,287

- Reaction score

- 10,288

I push the Wad down by itself

Idaholewis

Well-Known Member

- Joined

- Jun 30, 2017

- Messages

- 7,287

- Reaction score

- 10,288

A short video showing my loading sequence

- Joined

- Dec 11, 2020

- Messages

- 173

- Reaction score

- 237

Dr. Sam always advised to use Hornet Material on top of the powder to protect the patch when using patch and ball. A felt wad will do if Hornet nest i not available..

- Joined

- Feb 13, 2020

- Messages

- 1,730

- Reaction score

- 2,226

Guess we all do it different and I know I miss a lot ,there's my excuseI push the Wad down by itself

Idaholewis

Well-Known Member

- Joined

- Jun 30, 2017

- Messages

- 7,287

- Reaction score

- 10,288

Guess we all do it different and I know I miss a lot ,there's my excuse

With Wool Felt and Grease Groove Bullets it really doesn’t matter if you send the Wad Seperate or with the Bullet. The Important part is that you Start the Wad Straight in the Bore and make sure it doesn’t turn sideways, especially so with oversize Wool Wads like i prefer, if an oversize Wool felt Wad turns sideways it will stay that way all the way down

My Paper Patch Bullets are the reason that i started pushing the wad down by itself, Especially so with Hard Card wads like Vege Fibre, as they Load with very noticeable resistance. By pushing the Bullet down by itself it allows me to feel the Paper Patch Bullet all the way down without the Resistance of the Wad. I had a few BAD failures by sending the Bullet and Wad Together, I Pushed the Bullet through the Paper Jacket and didn’t realize it until i fired the Rifle, in which the Sound was a DEAD GIVE AWAY, and the Bullet didnt even make it to the Target. This would not have happened if i had pushed the Bullet down by itself, I would have felt the The Bullet push through the Paper Jacket

Last edited:

- Joined

- Feb 13, 2020

- Messages

- 1,730

- Reaction score

- 2,226

Makes sense ,however with paper patch my wad goes with cause I use the wad to help hold the patch to the base . It eliminated the patch slipping off and then a naked bullet with no patch ruining that load . Perhaps bore condition or my not sizing my patched bullet adequately is the reason ,but combining the 2 eliminates slipped patches and wasting that load . With todays black powder situation wasting powder is well (a waste) EdWith Wool Felt and Grease Groove Bullets it really doesn’t matter if you send the Wad Seperate or with the Bullet. The Important part is that you Start the Wad Straight in the Bore and make sure it doesn’t turn sideways, especially so with oversize Wool Wads like i prefer, if an oversize Wool felt Wad turns sideways it will stay that way all the way down

My Paper Patch Bullets are the reason that i started pushing the wad down by itself, Especially so with Hard Card wads like Vege Fibre, as they Load with very noticeable resistance. By pushing the Bullet down by itself it allows me to feel the Paper Patch Bullet all the way down without the Resistance of the Wad. I had a few BAD failures by sending the Bullet and Wad Together, I Pushed the Bullet through the Paper Jacket and didn’t realize it until i fired the Rifle, in which the Sound was a DEAD GIVE AWAY, and the Bullet didnt even make it to the Target. This would not have happened if i had pushed the Bullet down by itself, I would have felt the The Bullet push through the Paper Jacket

Lewis are you using any kind of lube on The wadWith Wool Felt and Grease Groove Bullets it really doesn’t matter if you send the Wad Seperate or with the Bullet. The Important part is that you Start the Wad Straight in the Bore and make sure it doesn’t turn sideways, especially so with oversize Wool Wads like i prefer, if an oversize Wool felt Wad turns sideways it will stay that way all the way down

My Paper Patch Bullets are the reason that i started pushing the wad down by itself, Especially so with Hard Card wads like Vege Fibre, as they Load with very noticeable resistance. By pushing the Bullet down by itself it allows me to feel the Paper Patch Bullet all the way down without the Resistance of the Wad. I had a few BAD failures by sending the Bullet and Wad Together, I Pushed the Bullet through the Paper Jacket and didn’t realize it until i fired the Rifle, in which the Sound was a DEAD GIVE AWAY, and the Bullet didnt even make it to the Target. This would not have happened if i had pushed the Bullet down by itself, I would have felt the The Bullet push through the Paper Jacket

Idaholewis

Well-Known Member

- Joined

- Jun 30, 2017

- Messages

- 7,287

- Reaction score

- 10,288

Lewis are you using any kind of lube on The wad

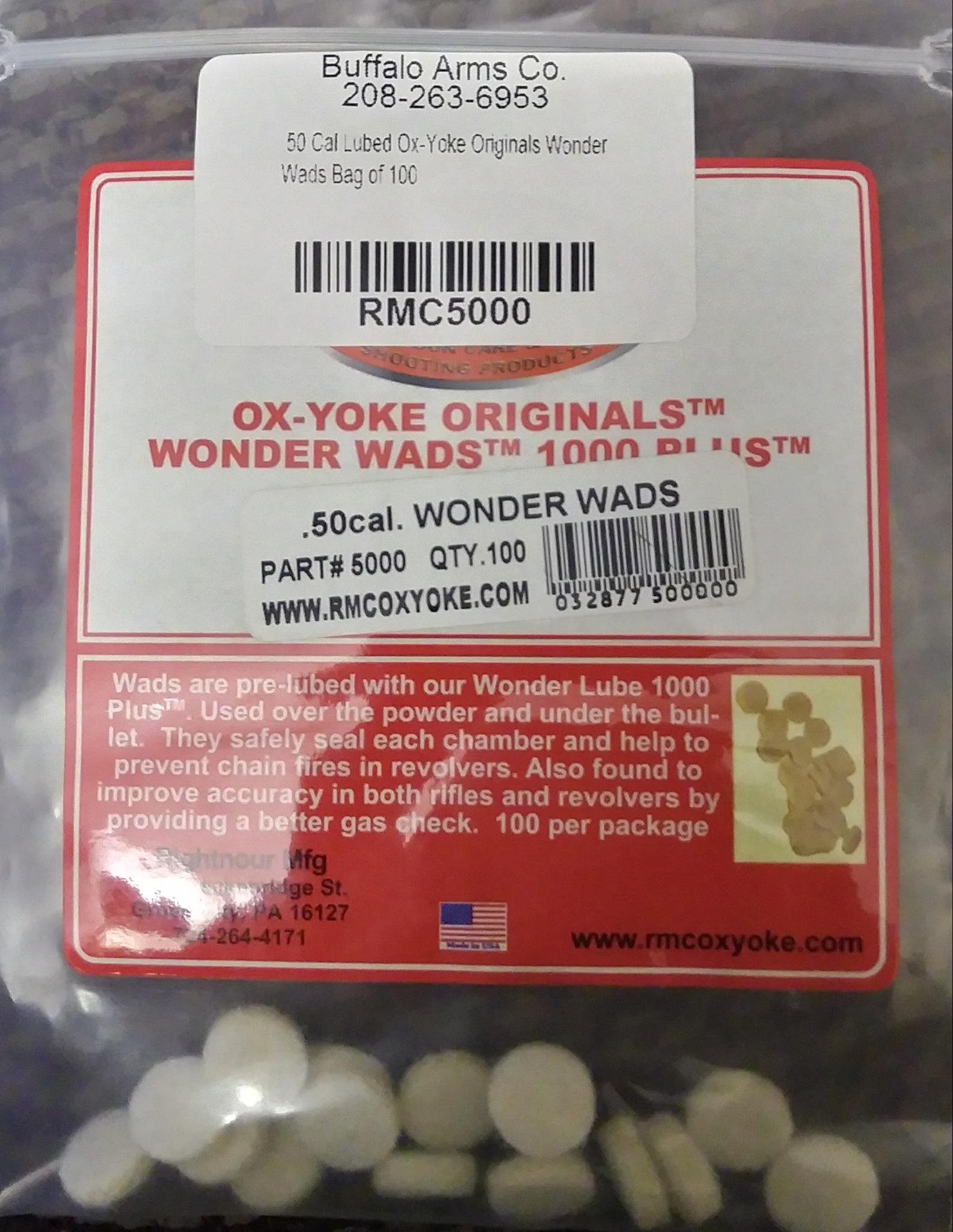

They are Factory Lubed

This the Brand i use, Ox-Yoke Lubed

- Joined

- May 19, 2005

- Messages

- 9,205

- Reaction score

- 1,740

What is the correct way to load them I've seen post on by theirselves or with the conical bullet, I'll be using the no excuse 420 in a vortex Northwest ultralight magnum rifle.

This is not the old way of doing this... and since you are shooting a 50 but have you ever heard of a MMP Sub Bridge.

This pic shows one inserted in the crown with the bullet sitting on top ready to be pushed down

No lube necessary and they completely seal the gas in the bore behind the bullet. They work great and are far easier to load and handle.

This pic shows a .503x400LGP Bull Shop conical recovered from an elk shot at 180+ yards. You can see the impression of the sub-base in the bottom of the bullet.

This a pic of the product... These subases were orinally built to protect the powder cup of a sabot from melting when shoot real rifle powder as in the Savage ML. They are Strong! They are not a part of the bullet and do not stay with the bullet once out of the muzzle.

just for information.

- Joined

- Jan 17, 2016

- Messages

- 1,265

- Reaction score

- 2,076

I have tried it both ways. Sending it by it self and with the conical. I found no difference in accuracy. I tend to send it with the conical. It helps save a little time.

Idaholewis

Well-Known Member

- Joined

- Jun 30, 2017

- Messages

- 7,287

- Reaction score

- 10,288

This is not the old way of doing this... and since you are shooting a 50 but have you ever heard of a MMP Sub Bridge.

This pic shows one inserted in the crown with the bullet sitting on top ready to be pushed down

No lube necessary and they completely seal the gas in the bore behind the bullet. They work great and are far easier to load and handle.

This pic shows a .503x400LGP Bull Shop conical recovered from an elk shot at 180+ yards. You can see the impression of the sub-base in the bottom of the bullet.

This a pic of the product... These subases were orinally built to protect the powder cup of a sabot from melting when shoot real rifle powder as in the Savage ML. They are Strong! They are not a part of the bullet and do not stay with the bullet once out of the muzzle.

just for information.

I am not saying that these wouldn’t work, But I personally would never use them with Lead Bullets, The Base of the Bullet is what Steers it, I don’t want anything making impressions in my Bullet Bases. 1/8” Wool Felt does a Fantastic Job with Lead Bullets, proven over n over

- Joined

- Oct 6, 2020

- Messages

- 448

- Reaction score

- 811

But what do us 45cal shooting guys do? MMP doesn't seem to make a BBSB in 45cal...at least not that I can find...This is not the old way of doing this... and since you are shooting a 50 but have you ever heard of a MMP Sub Bridge.

This pic shows one inserted in the crown with the bullet sitting on top ready to be pushed down

No lube necessary and they completely seal the gas in the bore behind the bullet. They work great and are far easier to load and handle.

This pic shows a .503x400LGP Bull Shop conical recovered from an elk shot at 180+ yards. You can see the impression of the sub-base in the bottom of the bullet.

This a pic of the product... These subases were orinally built to protect the powder cup of a sabot from melting when shoot real rifle powder as in the Savage ML. They are Strong! They are not a part of the bullet and do not stay with the bullet once out of the muzzle.

just for information.

Last edited:

- Joined

- May 19, 2005

- Messages

- 9,205

- Reaction score

- 1,740

I am not saying that these wouldn’t work, But I personally would never use them with Lead Bullets, The Base of the Bullet is what Steers it, I don’t want anything making impressions in my Bullet Bases. 1/8” Wool Felt does a Fantastic Job with Lead Bullets, proven over n over

I checked with Dan and even MMP both agree after looking the bullet there is no effect of the base impression on the accuracy of the bullet as the bore and the crown shape the exterior ballistics of the bullet. And I can agree with that out to 180+ yards with open sights. Both bullet shot hit the animal although one shot was a little to far to rear as the animal decided to move just as the second shot was on the way. The first shot hit well within the sighted location.

Last edited:

- Joined

- May 19, 2005

- Messages

- 9,205

- Reaction score

- 1,740

But do us 45cal shooting guys do? MMP doesn't seem to make a BBSB in 45cal...at least not that I can find...

I was really trying to get MMP to realize the fact that 45 cal ML shooters would really like to have sub-base also. They looked at it and I could not believe the price to work a developed mold for the project!

Del Ramsey was a devoted 45 shooter and was interested but COST was a huge factor! Then of course Del passed away a month or two ago.

I even thought about modifying a 45 cal. sabot. I'm just not sure how I would get the cuts even when I removed the petals. As of yet I have not tried to make the surgical cuts.

Similar threads

- Replies

- 3

- Views

- 395

- Replies

- 21

- Views

- 1K