- Joined

- Jan 25, 2017

- Messages

- 170

- Reaction score

- 29

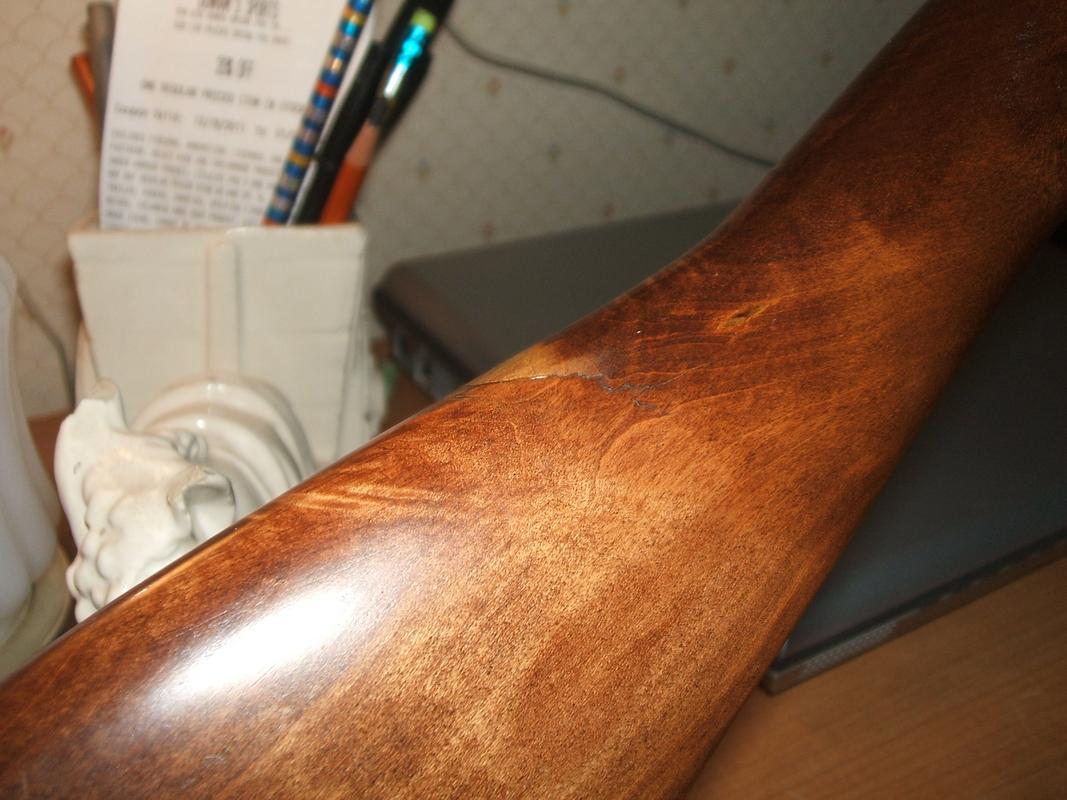

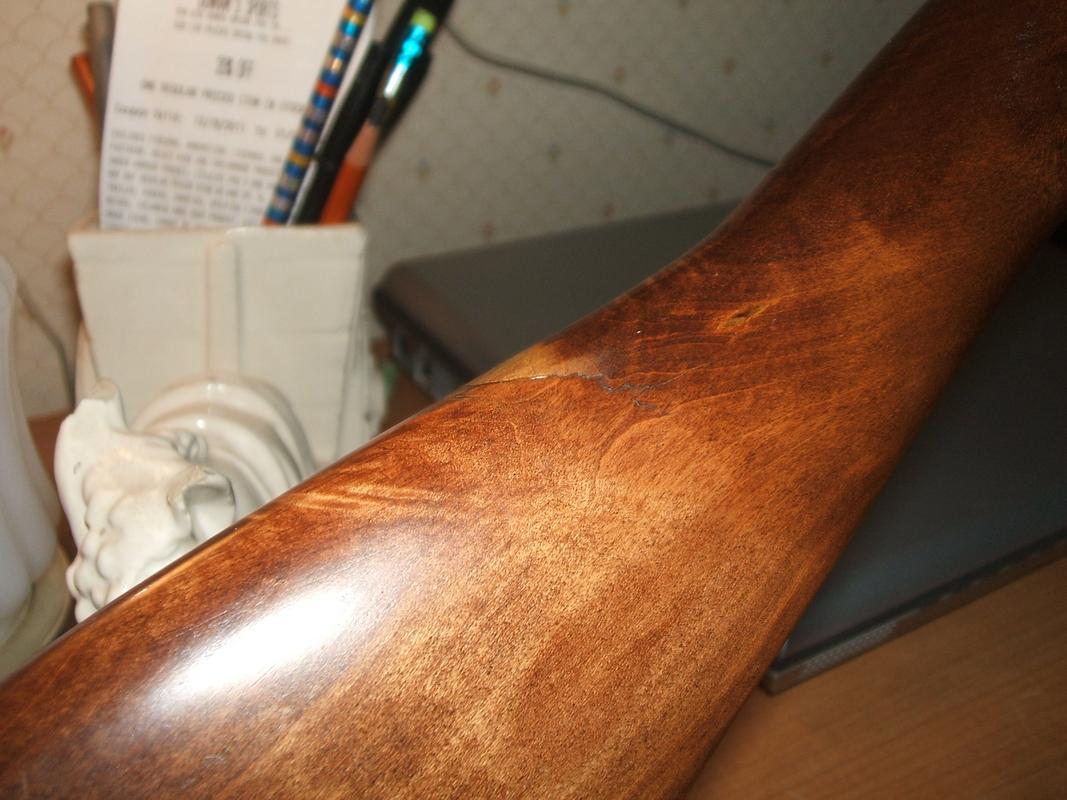

Richland Arms "Michigan" rifle rebuild.

Time for another show and tell repair/rebuild thread. I purchased this rifle to use for practice right after buying my Thompson Center Hawken. I got it real cheap due to a very defective stock. My plan was to work on this as a warmup before doing the TC to see if I could actually still do this sort of thing without hacking it up. The last time I had built a kit gun was in 1983. This rifle probably should have been restocked but wasn't. It had a knot that ran through the stock right at the wrist/comb area. First set of pictures show what the rifle looked like when purchased.

Time for another show and tell repair/rebuild thread. I purchased this rifle to use for practice right after buying my Thompson Center Hawken. I got it real cheap due to a very defective stock. My plan was to work on this as a warmup before doing the TC to see if I could actually still do this sort of thing without hacking it up. The last time I had built a kit gun was in 1983. This rifle probably should have been restocked but wasn't. It had a knot that ran through the stock right at the wrist/comb area. First set of pictures show what the rifle looked like when purchased.