After shooting Bucks custom GRRW flintlock and seeing how well it did with 6 grains 4fg Goex, I decided to hog out the pan on my Traditions Mountain Rifle flintlock. I first tried 3 grains and it was slow. Upped it to 6 grains and boom! Extremely fast ignition and out of 10 shots, not one had a flash in the pan.

The factory set up worked fine with a touch over 3 grains, but some times it would go into the touch hole because the bottom of the pan was almost level. It would give me some flash in the pans as well at times.

I still have some polishing to do once I get some stones, but right now, I am extremely happy!

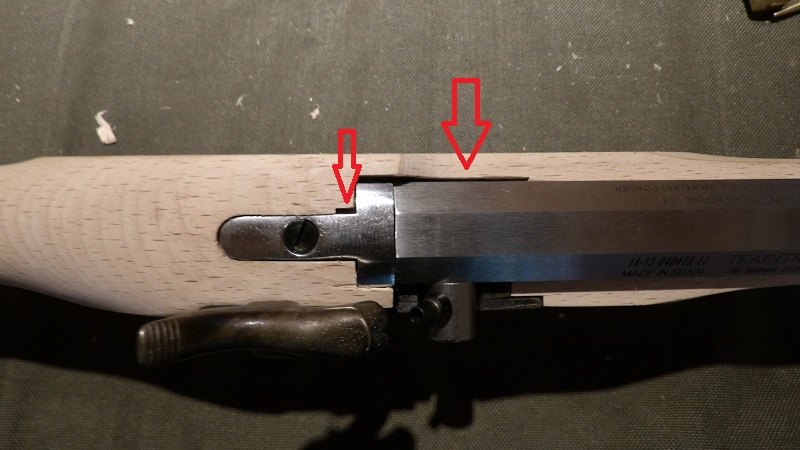

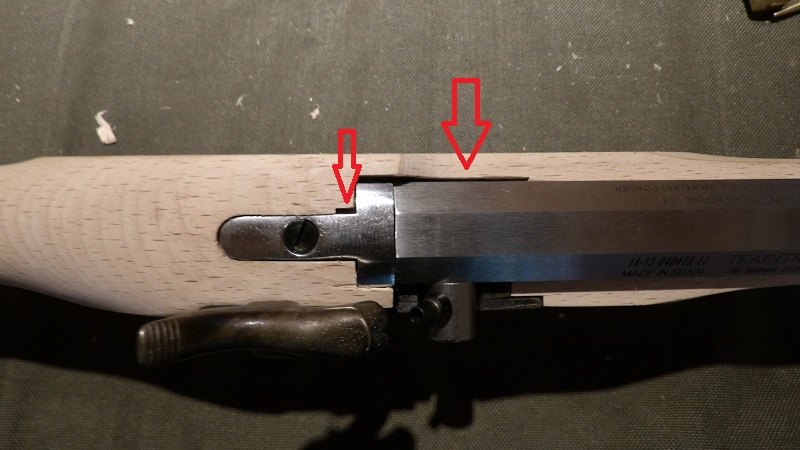

I haven't shot the rifle a lot since I built it, but I did note a little leak between the barrel and lock. I epoxied in a piece of brass shim stock ( used for shimming engine bearings ) and today, the lock mortise was spotless except for some polishing grease I currently am testing inside of the lock.

Super happy! I even took one shot, decided I need a lot more time to heal up before doing that again lol. Not bad though! Just a little discomfort in the muscles during recoil.

The factory set up worked fine with a touch over 3 grains, but some times it would go into the touch hole because the bottom of the pan was almost level. It would give me some flash in the pans as well at times.

I still have some polishing to do once I get some stones, but right now, I am extremely happy!

I haven't shot the rifle a lot since I built it, but I did note a little leak between the barrel and lock. I epoxied in a piece of brass shim stock ( used for shimming engine bearings ) and today, the lock mortise was spotless except for some polishing grease I currently am testing inside of the lock.

Super happy! I even took one shot, decided I need a lot more time to heal up before doing that again lol. Not bad though! Just a little discomfort in the muscles during recoil.