- Joined

- Jan 15, 2013

- Messages

- 1,066

- Reaction score

- 1,281

Lewis sent me some 416 gr paper patch bullets to try in my New Rifle here is a picture if you don't remember.

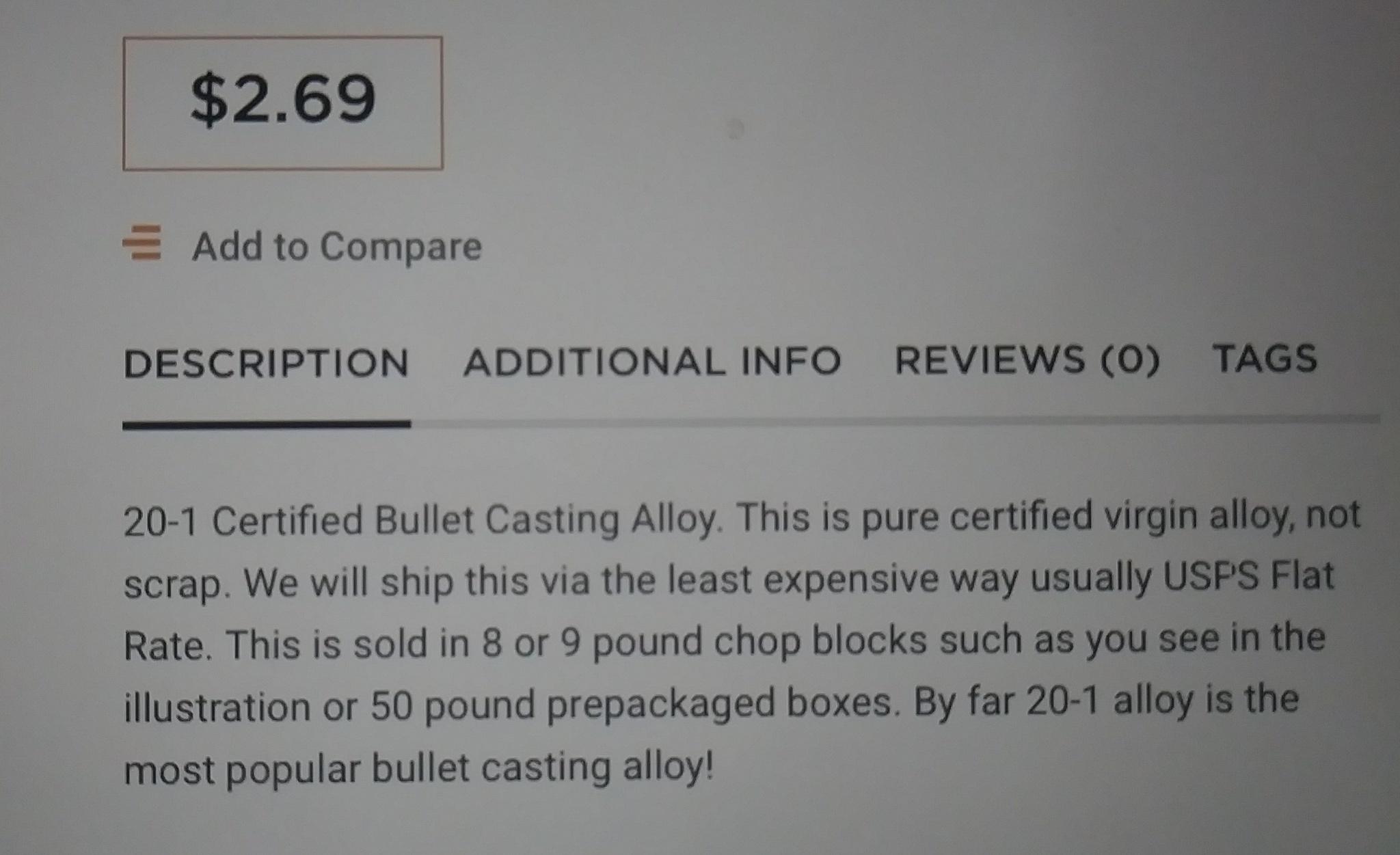

I had a hardness of .060 on my dial, that is about 9.2 BHN that's kind of a guess. It was between 9 and 9.5 BHN. I filed off the nose to get a wider spot to test the hardness.

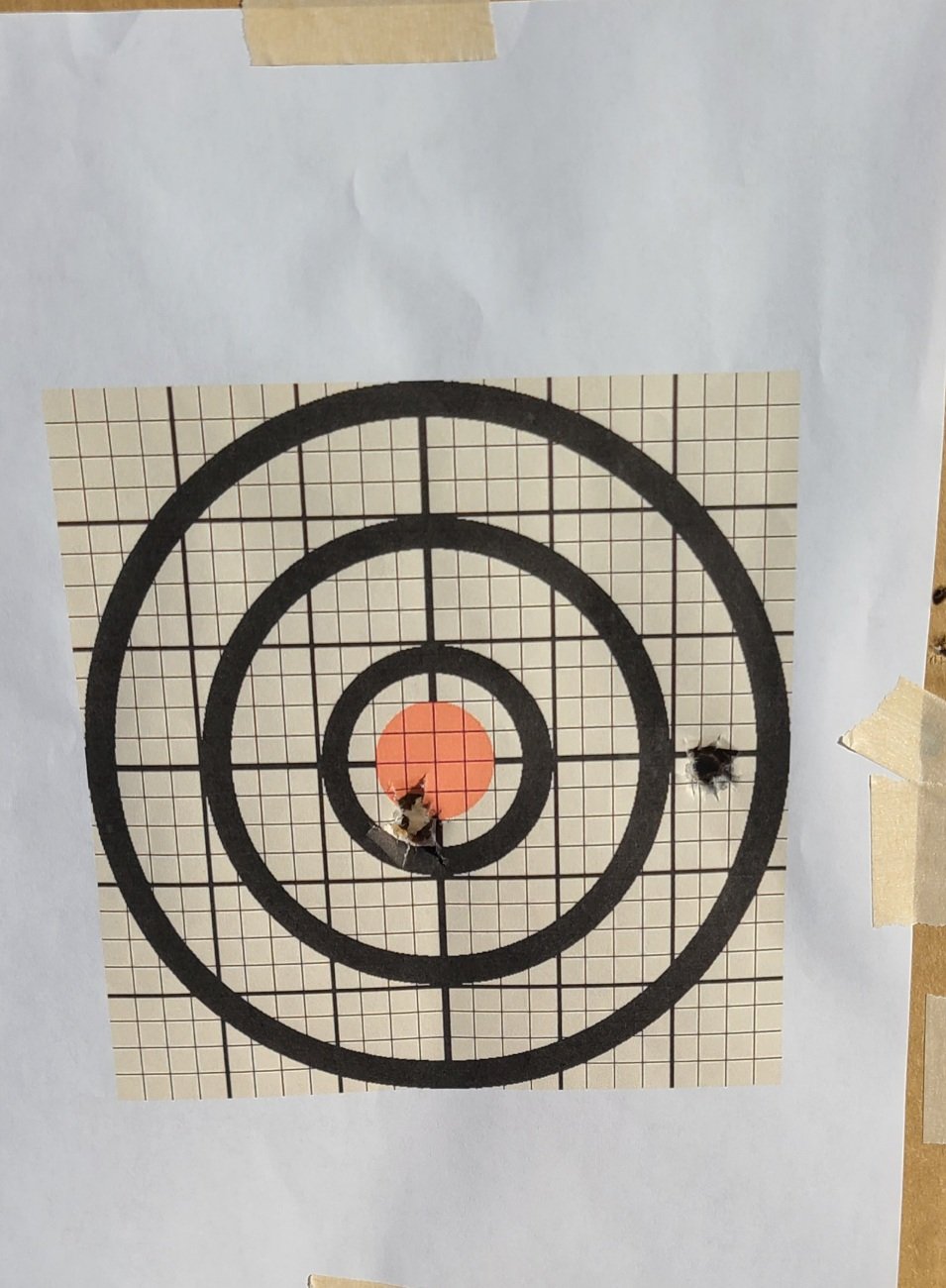

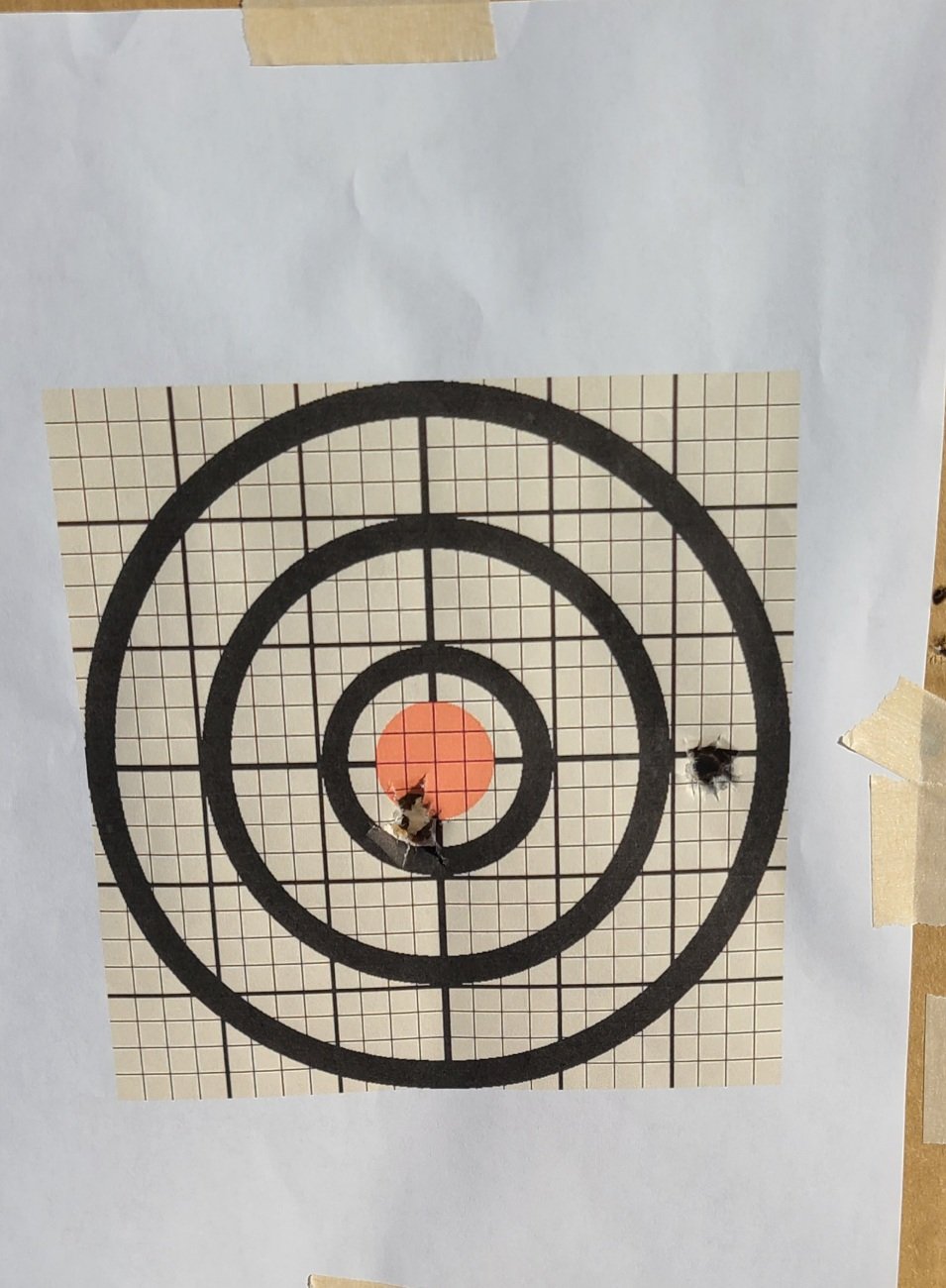

I was set at 100 yards and I used the setting I determined from the last shoot with my 11mm rifle bullets. I had a wind that was gusting 5 to 8 MPH left to right, here that is west to east.

The first shot was a cold clean bore. It was the farthest to the right. The second was the center shot.

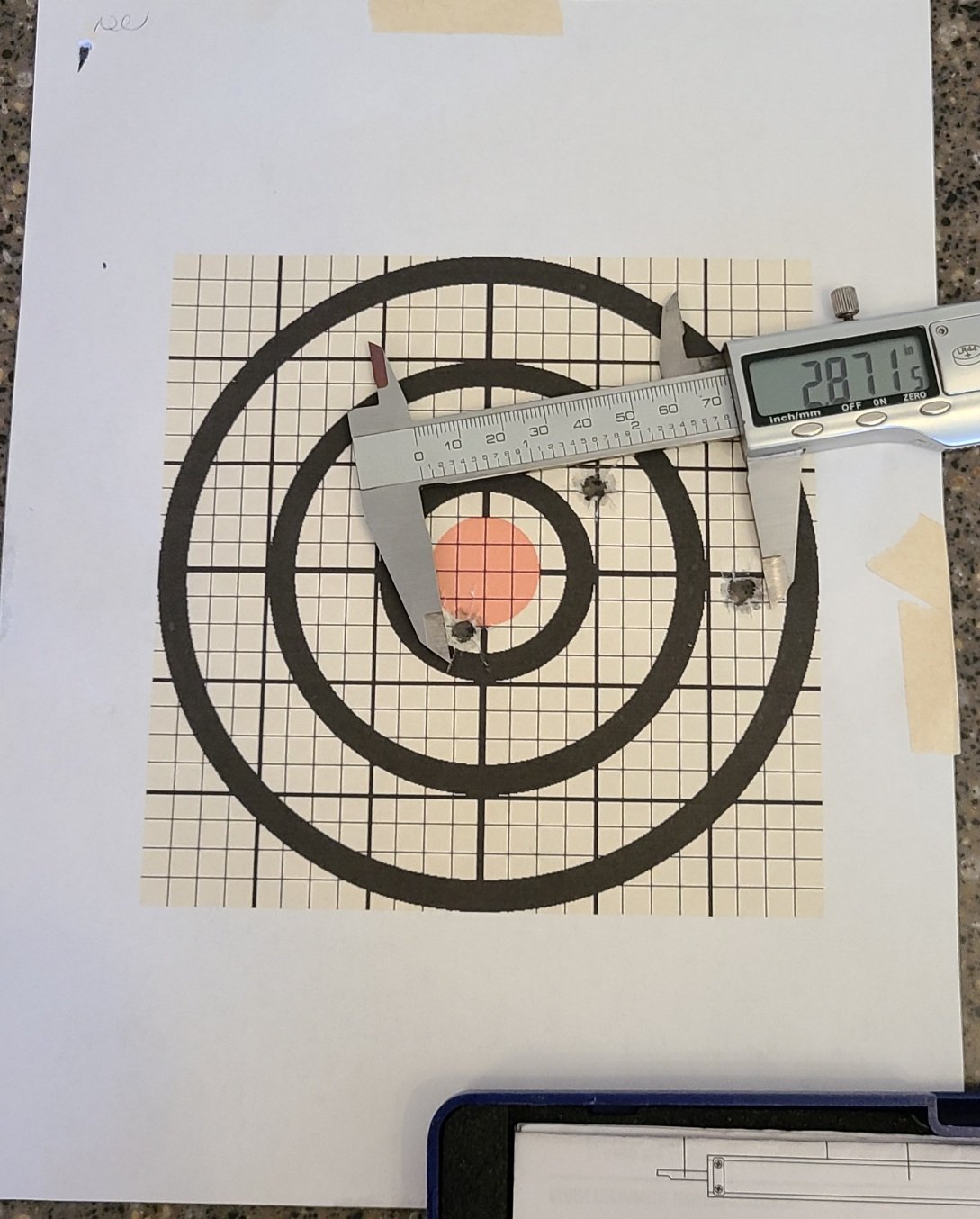

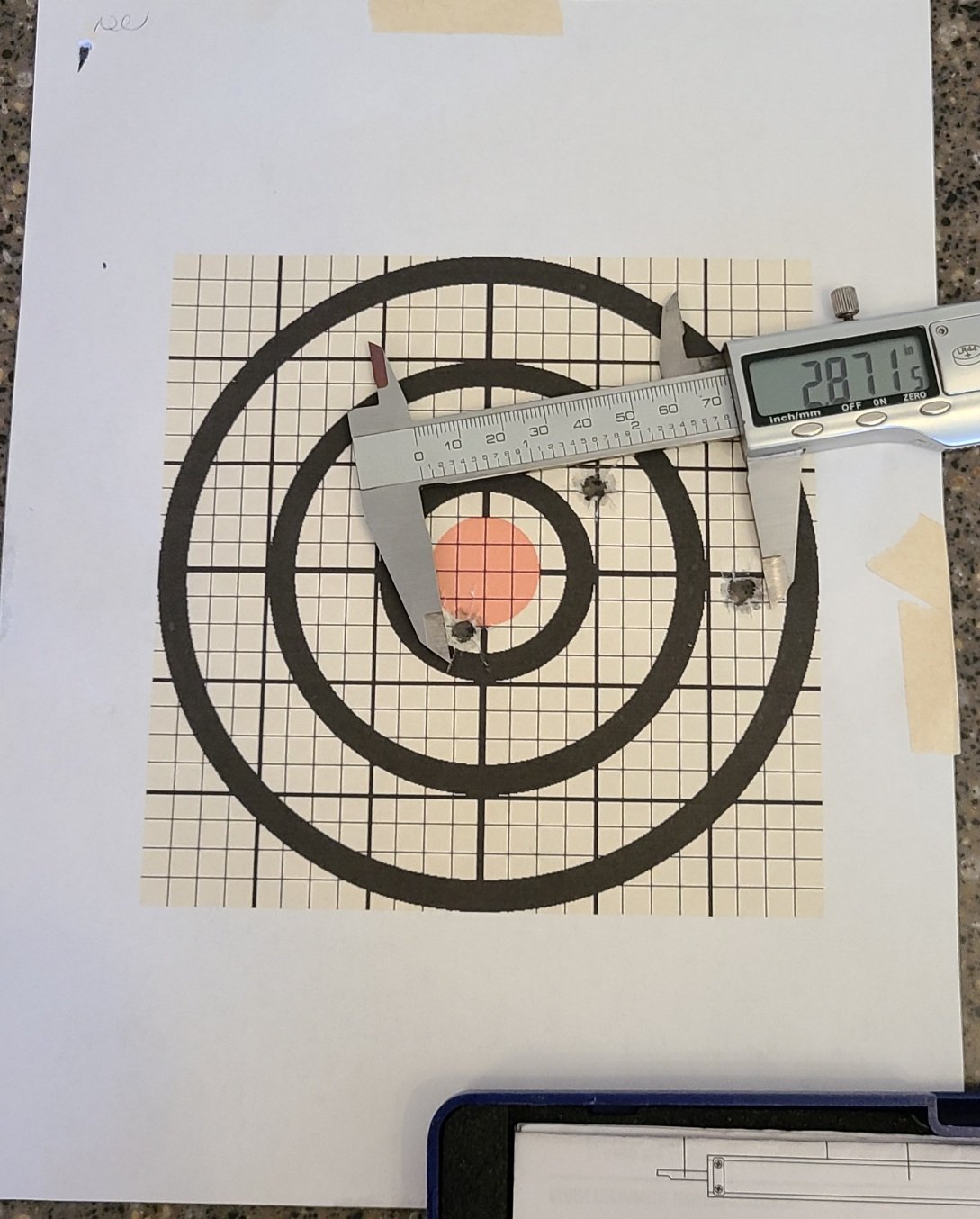

The third shot I was glad didn't affect the overall group but the wind was just what it was. The group size with the cold shot was 2.429"

I was very pleased with the group. The wind is just the wind, I wish I could get a calm day.

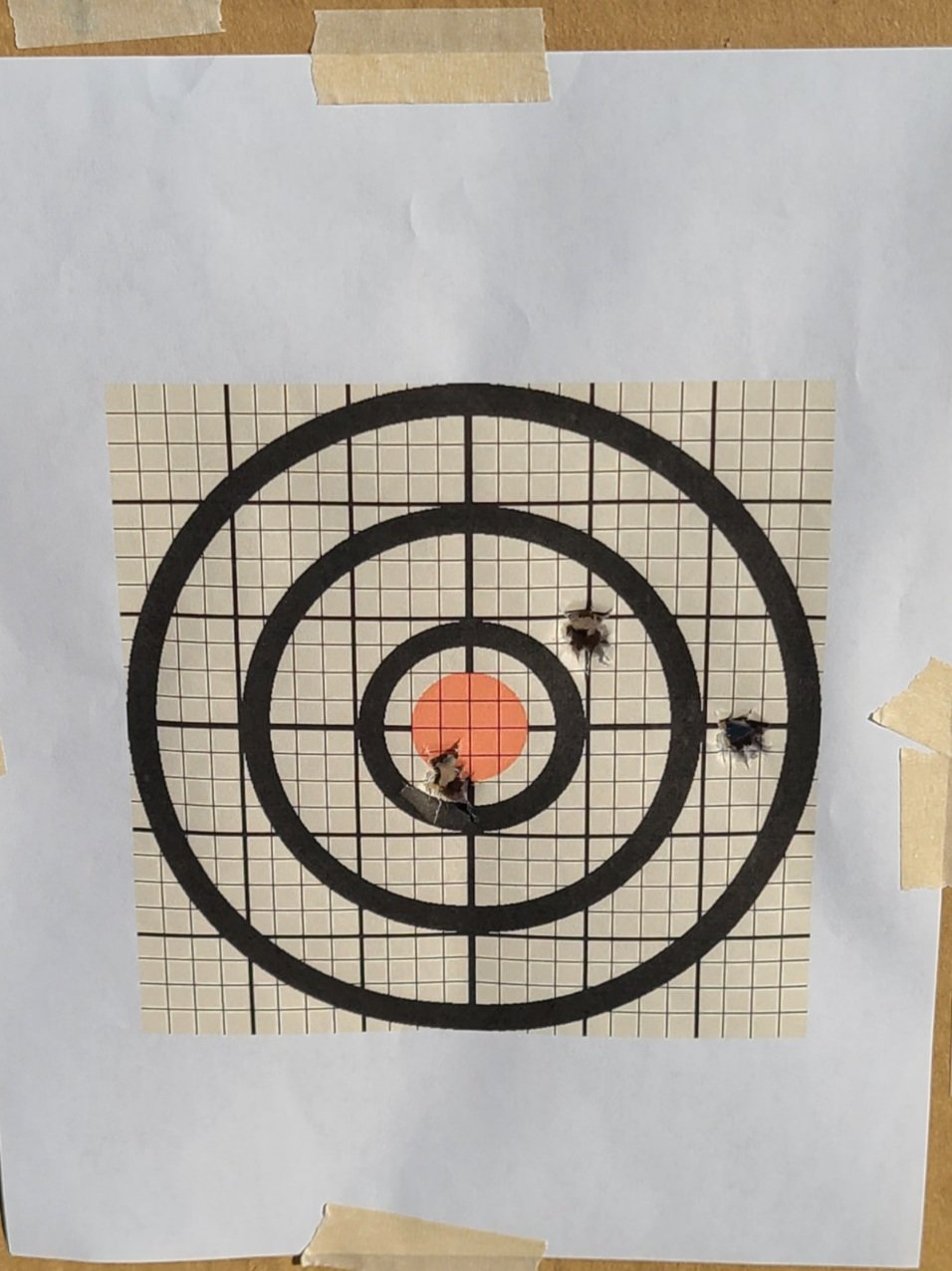

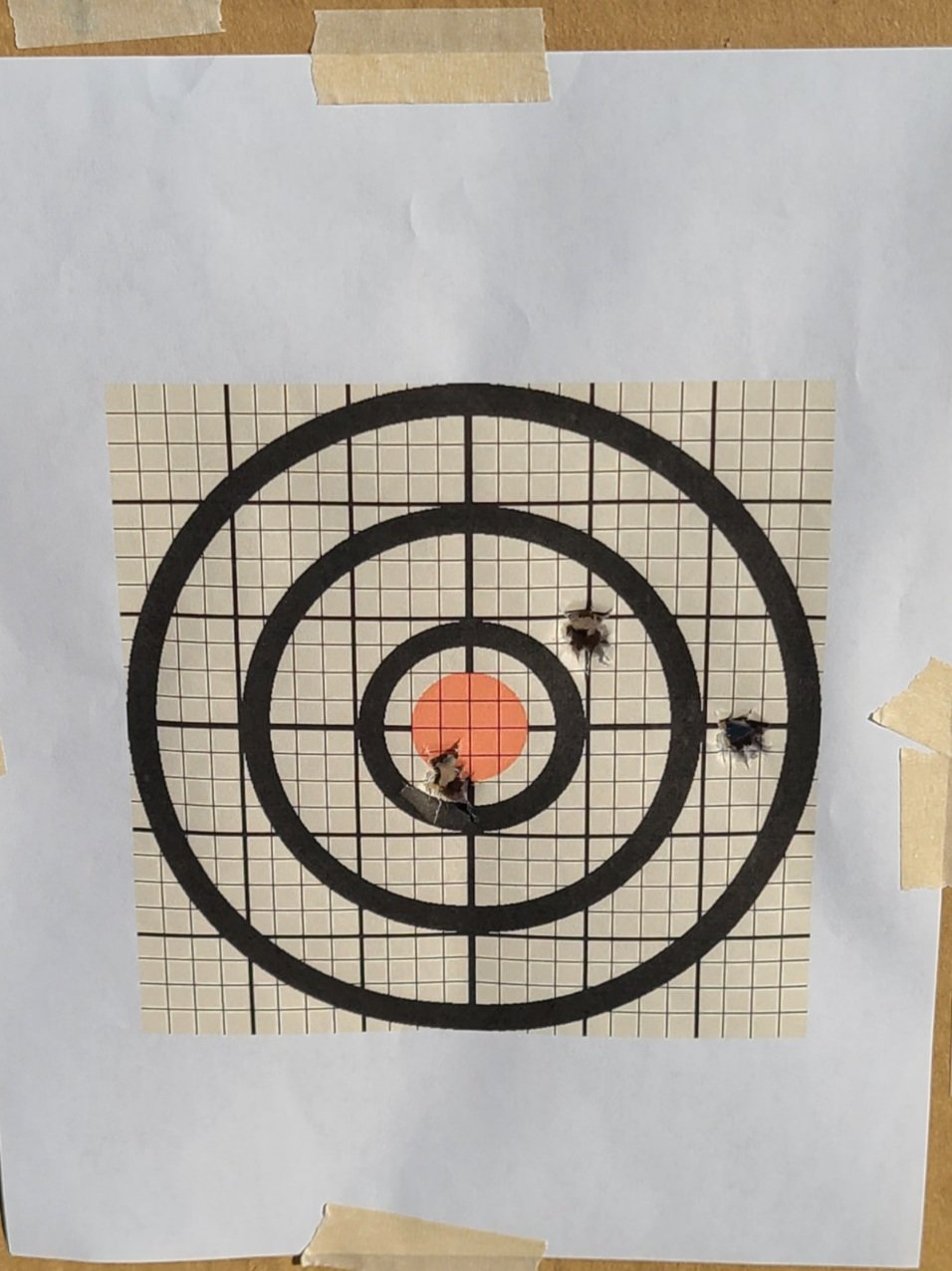

After my last range test I figured out what my MOA of drop was on my 11mm bullets in my Hawken. I wrote those MOA drops in my range note book. So I decided to go straight to 200 yards over my cross sticks no bench.

I set the Lee Shavers Mid range sight for .29 and took a shot. I didn't hold any windage, the wind was not real bad at that time. I could hear the impact.

I reloaded and took the same shot. Again impact.

I'm assuming that the second hit was the one with the lead still in the hole. The first one was the lower clean spot.

I was very pleased that the sight setting was spot on for elevation. The wind is just the wind.

Overall that bullet shot very well considering I just volume measured 80 gr of Pyrodex P and used a 50 cal over powder wad. I was very pleased that the cold bore shot was right there.

The bullets shot great. I will be testing them out farther next time.

I had a hardness of .060 on my dial, that is about 9.2 BHN that's kind of a guess. It was between 9 and 9.5 BHN. I filed off the nose to get a wider spot to test the hardness.

I was set at 100 yards and I used the setting I determined from the last shoot with my 11mm rifle bullets. I had a wind that was gusting 5 to 8 MPH left to right, here that is west to east.

The first shot was a cold clean bore. It was the farthest to the right. The second was the center shot.

The third shot I was glad didn't affect the overall group but the wind was just what it was. The group size with the cold shot was 2.429"

I was very pleased with the group. The wind is just the wind, I wish I could get a calm day.

After my last range test I figured out what my MOA of drop was on my 11mm bullets in my Hawken. I wrote those MOA drops in my range note book. So I decided to go straight to 200 yards over my cross sticks no bench.

I set the Lee Shavers Mid range sight for .29 and took a shot. I didn't hold any windage, the wind was not real bad at that time. I could hear the impact.

I reloaded and took the same shot. Again impact.

I'm assuming that the second hit was the one with the lead still in the hole. The first one was the lower clean spot.

I was very pleased that the sight setting was spot on for elevation. The wind is just the wind.

Overall that bullet shot very well considering I just volume measured 80 gr of Pyrodex P and used a 50 cal over powder wad. I was very pleased that the cold bore shot was right there.

The bullets shot great. I will be testing them out farther next time.

Wind SUCKS! And you guy’s live in it Down there. If you take the Cold Bore Shot out, Your last 2 were just under 1-1/2” (assuming the checks are 1” inch) The 2 on your Steel at 200 Yards look very Good

Wind SUCKS! And you guy’s live in it Down there. If you take the Cold Bore Shot out, Your last 2 were just under 1-1/2” (assuming the checks are 1” inch) The 2 on your Steel at 200 Yards look very Good