Please look at my post on previous page about shimming the primer pocket

It is a new Lehigh breech plug. I have been told the thread pocket of my gun (Knight LRH) may be deep. So may be the gun instead of the BP?

I tried metal shims first a few weeks ago. It took 3 (0.05) and I decided because it was so deep to try an O ring. Even though it is a bolt gun, that seem to work well for my shoot this weekend (10 shots) but the divit the firing pin makes with the O ring ((which completely eliminated blow back) is not as deep.

All primers went off

Ok - I was perusing the dimpled primer situation. But if all primers did ignite than that is not the problem. It continues to be the necessity of some method of shimming either O ring or shims.

I am still somewhat amazed that it only took three .005 shims to create a primer crush. I assume you were using .241x.005 shims. Eventually you will need to install at least one .248x.005 shim to hold everything in place when you are sure you are getting primer crush.

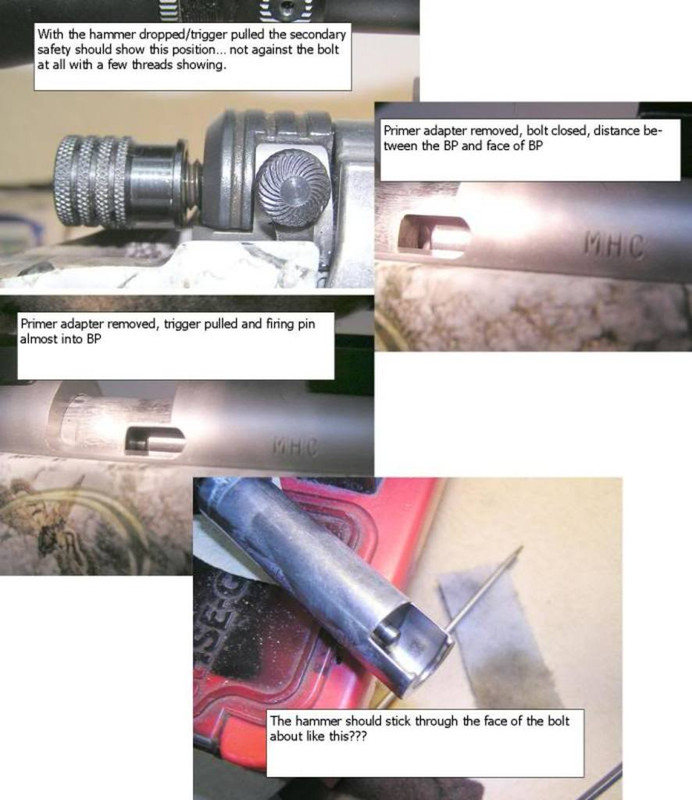

So, I am going to step off base once again. When you were shimming and testing for crush did you remove the hammer assembly from the bolt and only use the bare bolt body testing for primer crush. With the hammer assembly in the bolt and testing you can get a false reading at times.

With the hammer assembly removed insert the bolt body in the rifle then push the bolt forward to close - release the bolt handle while it is at the top and the handle should drop to the closed position and contact the receiver. Next install the shims and repeat the test with a primer in place. When the bolt drops nearly 2/3 rds of the way down and stops you should have the correct amount of shimming to create primer crush and a tight headspace.

I really should have asked what primer you are using, of course that makes a big difference in getting the correct head space. One other thing posted by Ron L. the new W209 primers are not as long as they use to be. Much closer to what the regular CCI 209 primer measures.

I am excited that you have a Lehigh 17-4 plug in the rifle versus the Knight 416 SS plug. And I really do prefer the Lehigh primer adapter.

Really hope I am not creating a headache for you!

Also, at this moment I cannot locate the picture of the extended to the BP stack that I am looking for to illustrate the distance the hammer is from the BP stack. I will continue to look

mike

. Ive given away a lot of orings and shims but still have enuff for my lifetime

. Ive given away a lot of orings and shims but still have enuff for my lifetime