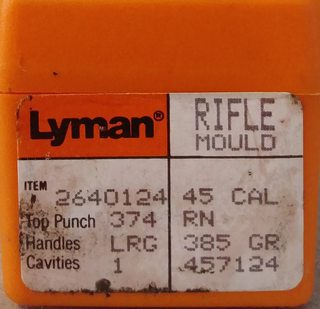

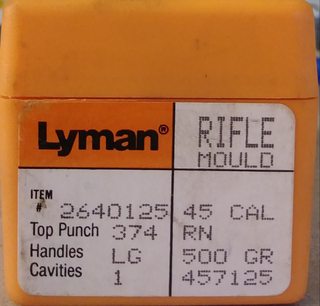

Yes on these for initial testing, I size per bore, So they just “Kiss” the Rifling on the Way Down.

It’s not ideal to Have to Size .457-.459 Bullets down to .449-.450, Some advise against it. But fact is you can definitely do it, And Accuracy has been AWESOME for me. A Lot Depends on the Bullet Design? If it is an “Inset” Lube Groove Design, or one with “Exterior” Bands, This Can make a difference in how Easily they size. The

KEY is Plenty of Lube All over the Bullet (I use a Lube Pad), and

SPEED through the Sizer. I even Pre Lube the inside of my Sizing Die. Depending on the Lube Groove design? I might size them in 2 Steps, .454, then .450, With PLENTY of Lube, and SPEED, These Bullets will Go Through the Sizer EFFORTLESSLY.

Try the above method with NO LUBE, and Go Slow. If you are a Quick learner, You will only do that one time

It’s almost guaranteed that the Bullet will get STUCK in the Die, If by Chance you get it Through? The Bullet will be RUINED! The Base will be Destroyed from the Push Rod, and you will have “Finning” Down the Sides of the Bullet, Totally Ruining it.