Idaholewis

Well-Known Member

- Joined

- Jun 30, 2017

- Messages

- 7,287

- Reaction score

- 10,289

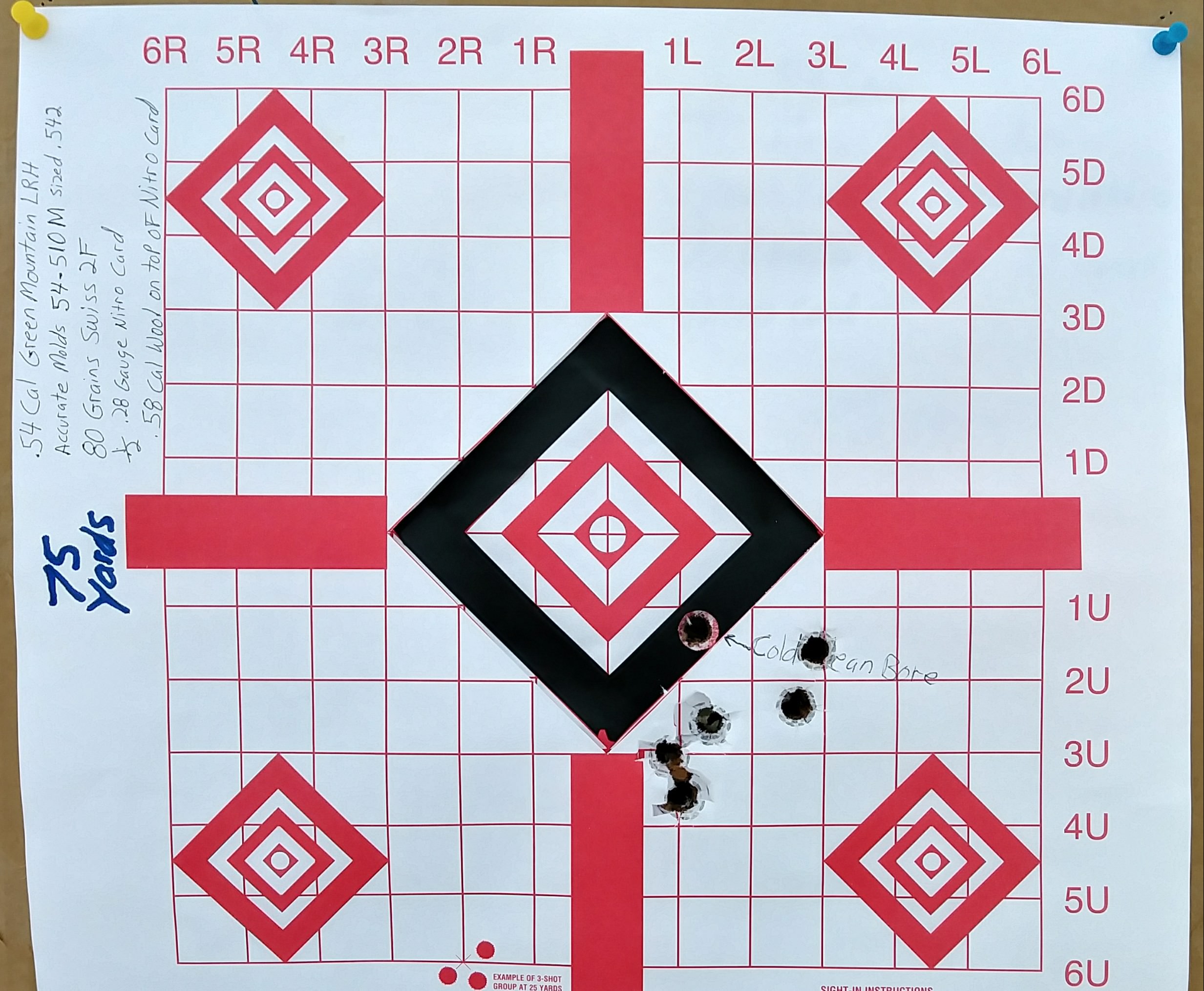

Accurate Molds 54-510M, (These weigh 520 Grains) Pan lubed and sized to .542, I was playing around with bullet fit yesterday in my Green Mountain .54 Cal LRH Barrel (1:28 Twist) i ended up opening a .538 finish sizer die to .542 For my .54 Grease Groove bullets, I just don’t use the .538 anymore (i use a .539 finisher for my .54 PP bullets) I worked slowly opening the die, checking fit frequently, I have These running right on 541.5-.542, I went ahead and loaded the Rifle with 80 Grains of Swiss 2F, Bullet fit is ideal in my opinion, they start good, and hold good and tight all the way down, Alloy is Certified 40:1, I am hoping to try these soon (maybe tomorrow?)

When i had this mold made i decided to enlarge the bands a bit for a Tight fitting Hunting bullet, i went with .543 Bottom 2 bands, .545 3rd band, and .546-.547 Top band, After playing around with my .45 Bullets lubed and sized to .451.5-.452 i was impressed at how they loaded, and shot (THANK YOU for the tip Edmehlig!!) I have decided to run all 3 Calibers of my Grease Groove bullets this way, it is a really slick method! Pan lube them and slide them through the sizer, The end result is a perfectly lubed and sized bullet ready to go. Another neat thing about an oversize bullet like this, is I can always go back and shoot these full diameter if they don’t work to my liking sized, So far i am REALLY impressed with my whole array of .45 GG bullets sized to .451.5-.452 like Ed does. I will likely buy a Lee .501 Sizer for my .50 Cal GG bullets and polish it out to .501.5-.502

Here are the bullets lubed, sized, and ready for testing, Hopefully have a target to Ad to this tomorrow

When i had this mold made i decided to enlarge the bands a bit for a Tight fitting Hunting bullet, i went with .543 Bottom 2 bands, .545 3rd band, and .546-.547 Top band, After playing around with my .45 Bullets lubed and sized to .451.5-.452 i was impressed at how they loaded, and shot (THANK YOU for the tip Edmehlig!!) I have decided to run all 3 Calibers of my Grease Groove bullets this way, it is a really slick method! Pan lube them and slide them through the sizer, The end result is a perfectly lubed and sized bullet ready to go. Another neat thing about an oversize bullet like this, is I can always go back and shoot these full diameter if they don’t work to my liking sized, So far i am REALLY impressed with my whole array of .45 GG bullets sized to .451.5-.452 like Ed does. I will likely buy a Lee .501 Sizer for my .50 Cal GG bullets and polish it out to .501.5-.502

Here are the bullets lubed, sized, and ready for testing, Hopefully have a target to Ad to this tomorrow