Buck Conner1

Well-Known Member

- Joined

- Oct 20, 2015

- Messages

- 4,592

- Reaction score

- 558

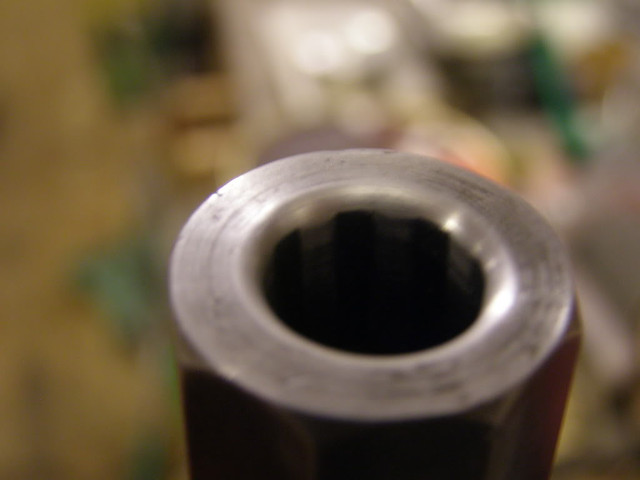

SUBJECT: Coning a barrel (my way)...

This procedure, in the present day is known as "coning". ie a "coned" muzzle. It was known in the 19th century as "relieving", ie; a "relieved" muzzle and also as "funneling", ie a "funneled" muzzle. There is very little historical data written about this as the gunsmiths' apprentice was taught the "hands on" method and not from a text book.

When these "hand taught" barrels makers passed on all their secrets died with them. I have examined many original m-loading barrels and there is definately a "funneling" at the muzzle. Some historians thought this "funneling" might be ram rod wear but that does not appear to be the case. One of the most interesting quotes on this subject is that of the famous Bill Large (now deceased). Bill was one of the founding Fathers of the NMLRA and one of the earliest 20th century barrel makers who helped pioneer the resurection of the m-loading rifle. Bill Large barrels are coveted today.

In a letter to John Baird who wrote "HAWKEN RIFLES, THE MOUNTAIN MANS CHOICE". Bill stated that he had re-bored and rifled 25 to 30 original Hawken barrels!!!!---- He also stated---"all were belled and showed signs of the funneling tool commonly used by most gunsmiths, as a request of the owner, to permit easy and fast reloading"""".

I just ordered one, have several friends that have them and swear by this method.

http://americanlongrifles.org/forum/index.php?PHPSESSID=lelor25lf4ecthf4l82g32k0c6&topic=4375.msg40866#msg40866

This procedure, in the present day is known as "coning". ie a "coned" muzzle. It was known in the 19th century as "relieving", ie; a "relieved" muzzle and also as "funneling", ie a "funneled" muzzle. There is very little historical data written about this as the gunsmiths' apprentice was taught the "hands on" method and not from a text book.

When these "hand taught" barrels makers passed on all their secrets died with them. I have examined many original m-loading barrels and there is definately a "funneling" at the muzzle. Some historians thought this "funneling" might be ram rod wear but that does not appear to be the case. One of the most interesting quotes on this subject is that of the famous Bill Large (now deceased). Bill was one of the founding Fathers of the NMLRA and one of the earliest 20th century barrel makers who helped pioneer the resurection of the m-loading rifle. Bill Large barrels are coveted today.

In a letter to John Baird who wrote "HAWKEN RIFLES, THE MOUNTAIN MANS CHOICE". Bill stated that he had re-bored and rifled 25 to 30 original Hawken barrels!!!!---- He also stated---"all were belled and showed signs of the funneling tool commonly used by most gunsmiths, as a request of the owner, to permit easy and fast reloading"""".

I just ordered one, have several friends that have them and swear by this method.

http://americanlongrifles.org/forum/index.php?PHPSESSID=lelor25lf4ecthf4l82g32k0c6&topic=4375.msg40866#msg40866