- Joined

- Dec 29, 2007

- Messages

- 4,956

- Reaction score

- 3,145

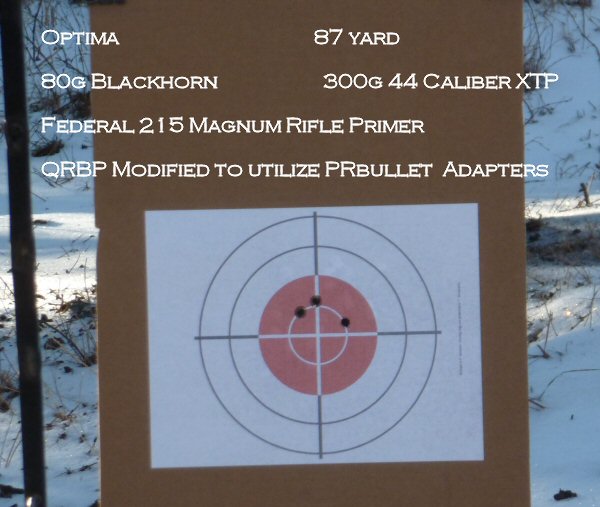

To me, the dimensions of the Blackhorn QRBP are better suited to using rifle primers, not shotgun primers. A couple of days ago a rifle, and a couple of breech plugs came in the mail, so yesterday morning the flash hole of the Blackhorn plug was enlarged to 0.035", and a dutchman was put into the mortice along with some red loctite. The dutchman was made by cutting a small piece off the QRBP fitment tool. Using JB Weld to fill the mortice was considered, but in the end, the dutchman was used instead.

This morning the loctite had hardened, so the plug was turned in a lathe till the dutchman was flush. Then the primer socket was enlarged in a mill, so the Precision Rifle large rifle primer adapters could be used. The socket was also made deep enough so that an o-ring would fit, and allow the rifle to go into battery, and the hammer be cocked.

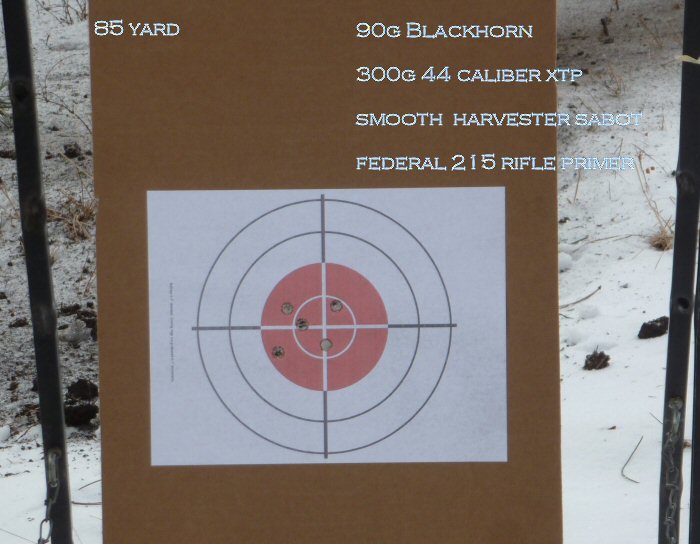

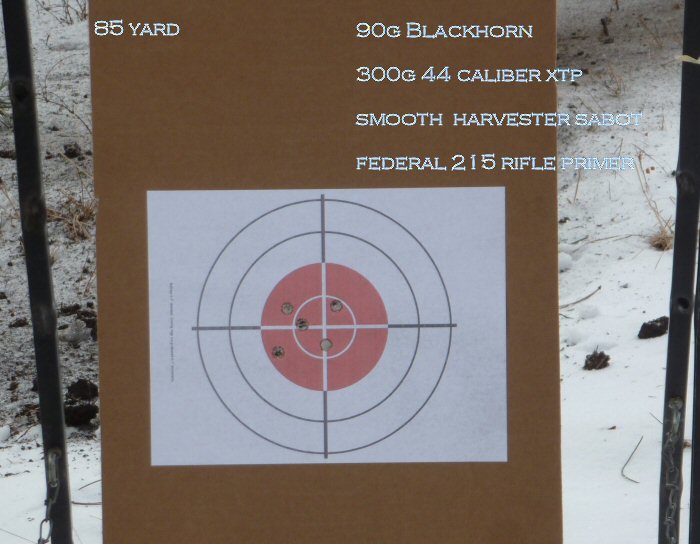

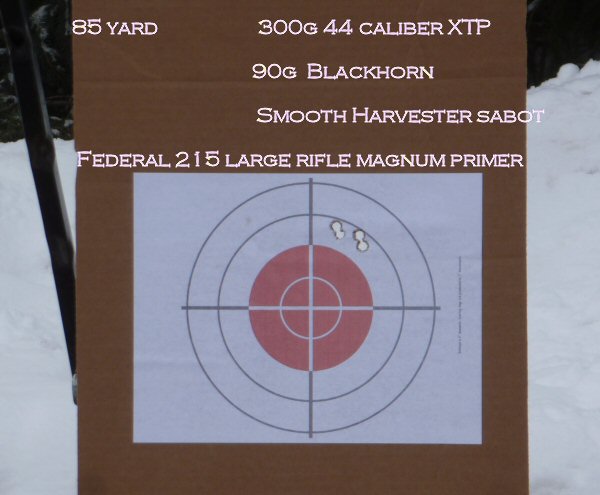

The shooting set today, was just about the same as yesterday, except the truck was parked one foot further away, and it was 4 degree, instead of 6 degree. Five shots were taken at 85 yard plus 1 foot. The scope setting was the same as yesterday' final setting.

The Blackhorn QRBP didn't fit the barrel as nicely as the QRBP used yesterday, but ignition was perfect, even though there is some blow by. Turning the plug in the lathe to flush the dutchman was more difficult than i envisioned, so now i am wishing i would have used JB Weld to fill the mortice..

This morning the loctite had hardened, so the plug was turned in a lathe till the dutchman was flush. Then the primer socket was enlarged in a mill, so the Precision Rifle large rifle primer adapters could be used. The socket was also made deep enough so that an o-ring would fit, and allow the rifle to go into battery, and the hammer be cocked.

The shooting set today, was just about the same as yesterday, except the truck was parked one foot further away, and it was 4 degree, instead of 6 degree. Five shots were taken at 85 yard plus 1 foot. The scope setting was the same as yesterday' final setting.

The Blackhorn QRBP didn't fit the barrel as nicely as the QRBP used yesterday, but ignition was perfect, even though there is some blow by. Turning the plug in the lathe to flush the dutchman was more difficult than i envisioned, so now i am wishing i would have used JB Weld to fill the mortice..

:huh?:

:huh?: