MUCH better

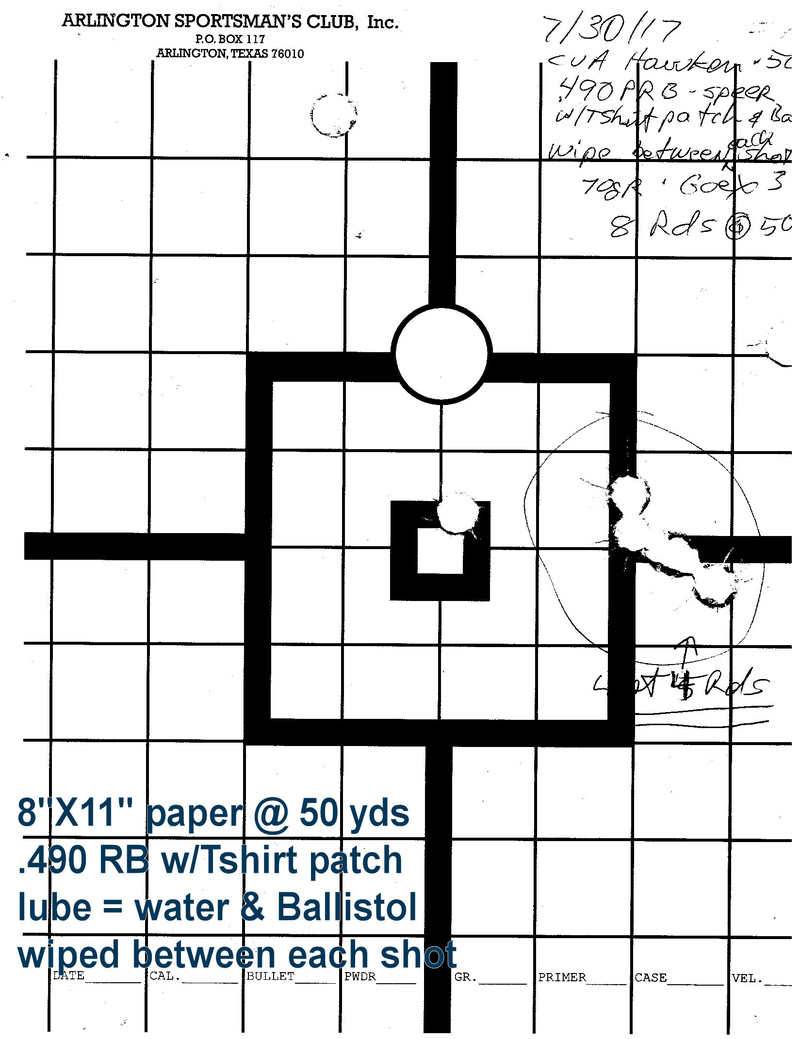

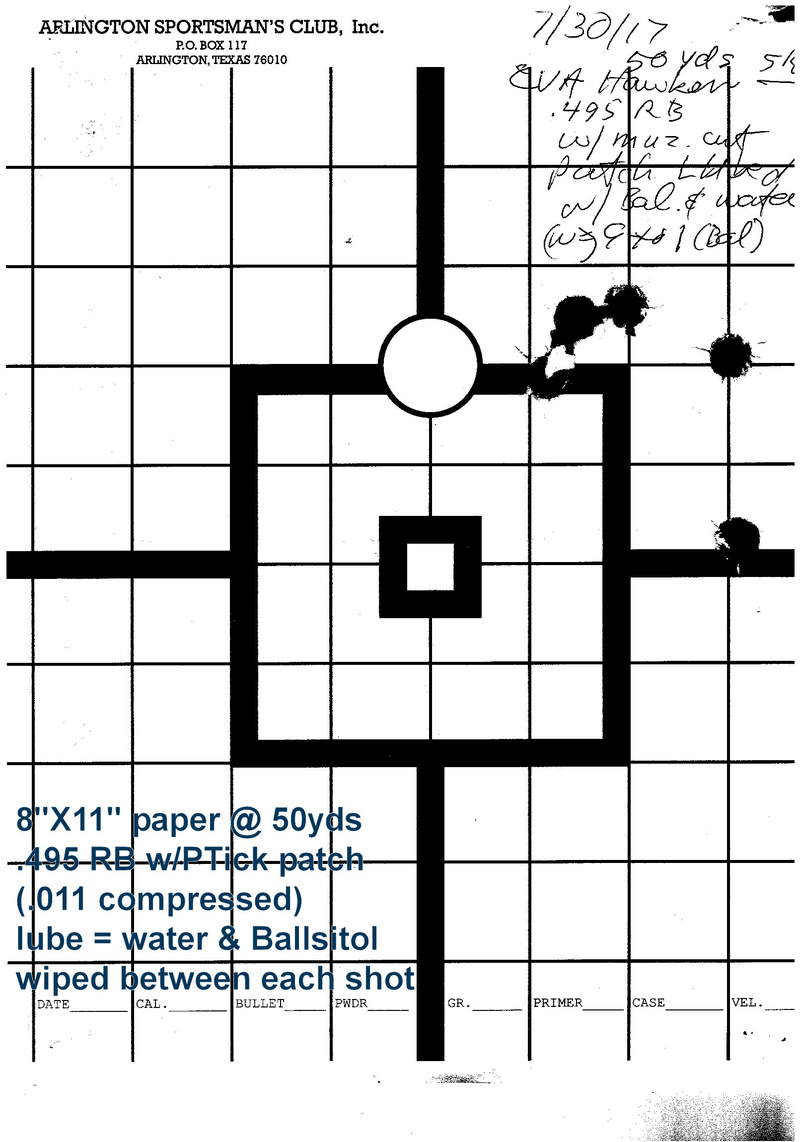

Went to the range for the first time in a month or so. My back issue is much better although not completely healed. The two targets posted here show the results of a tighter fitting ball/patch combo. One shows the results of .495 RB using a ticking patch and the other shows the results of a .490 RB using a Tshirt patch. Both patch types were lubed with a water/Ballistol mix.

These targets show a vast improvement over the first batch using .490 RB and thin ticking patches.

Both combinations fit tighter down the bore but, I think there is room for improvement. Next trip I'll be testing the .495 RB with the thicker Tshirt patch. If tighter is better, that should do the trick.

One issue I'm still having is blown out patches. Not just burned ....blown out. The entire center of every patch was blown completely out. Not sure what's causing that but, I've read that it's not a good thing.

Anyway, here's the targets. Notice i didn't try to adjust the sights. I was happy it was finally grouping. Next time I'll give some "left" and see what happens.

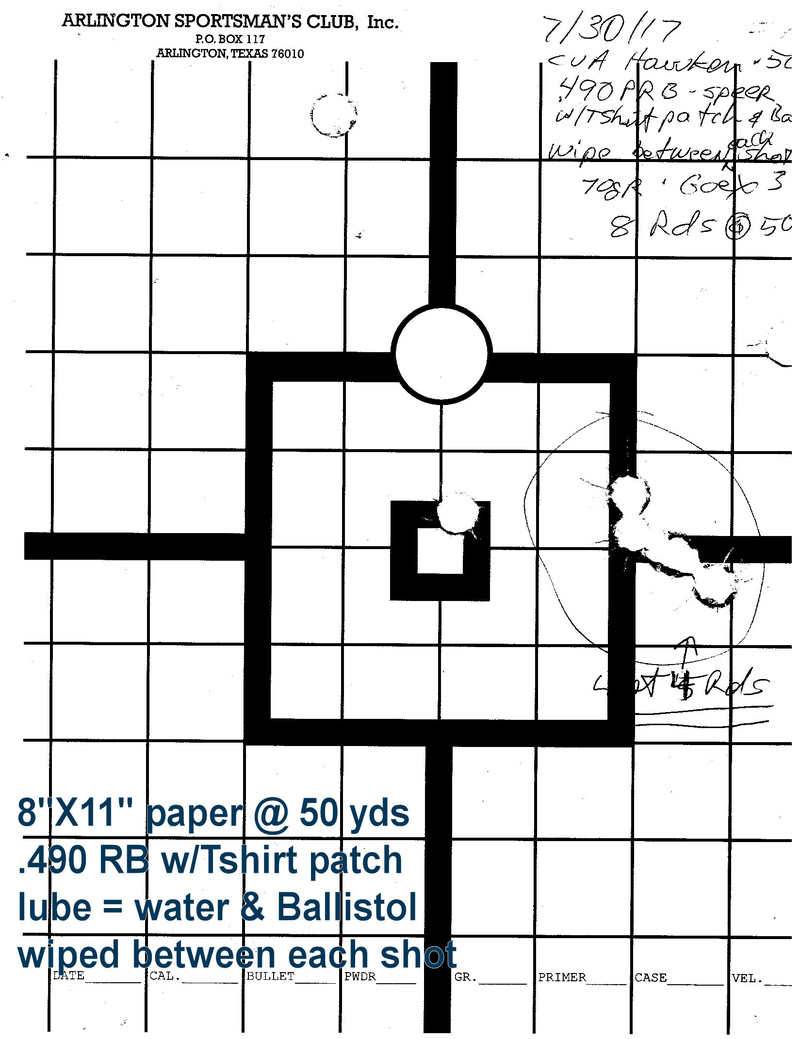

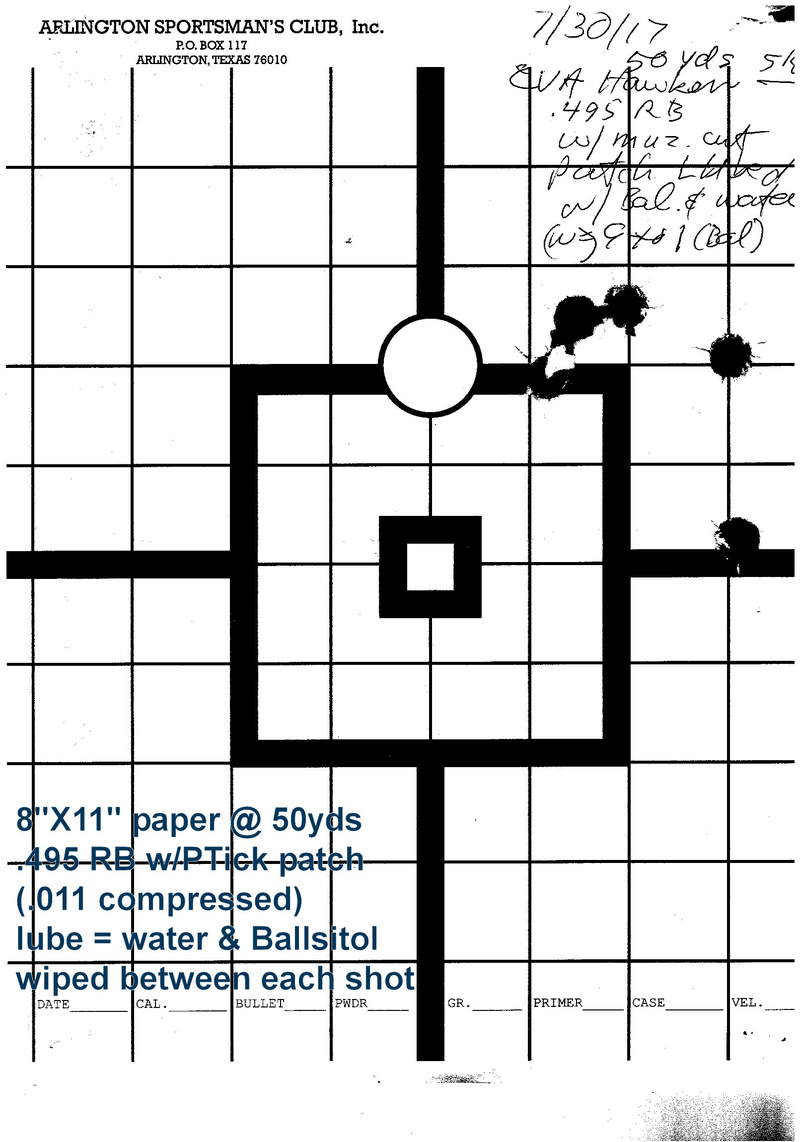

Went to the range for the first time in a month or so. My back issue is much better although not completely healed. The two targets posted here show the results of a tighter fitting ball/patch combo. One shows the results of .495 RB using a ticking patch and the other shows the results of a .490 RB using a Tshirt patch. Both patch types were lubed with a water/Ballistol mix.

These targets show a vast improvement over the first batch using .490 RB and thin ticking patches.

Both combinations fit tighter down the bore but, I think there is room for improvement. Next trip I'll be testing the .495 RB with the thicker Tshirt patch. If tighter is better, that should do the trick.

One issue I'm still having is blown out patches. Not just burned ....blown out. The entire center of every patch was blown completely out. Not sure what's causing that but, I've read that it's not a good thing.

Anyway, here's the targets. Notice i didn't try to adjust the sights. I was happy it was finally grouping. Next time I'll give some "left" and see what happens.