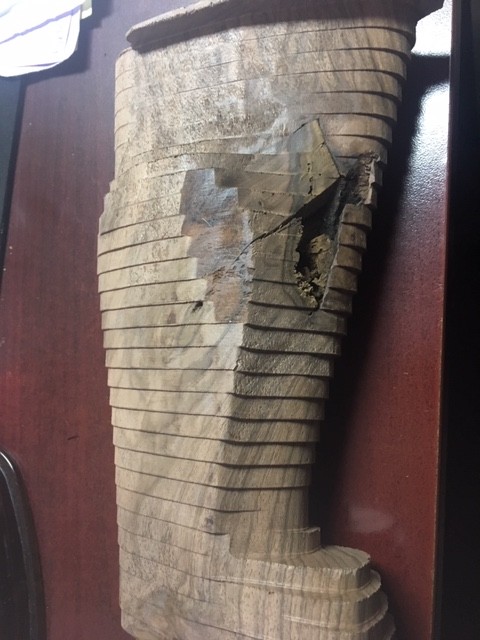

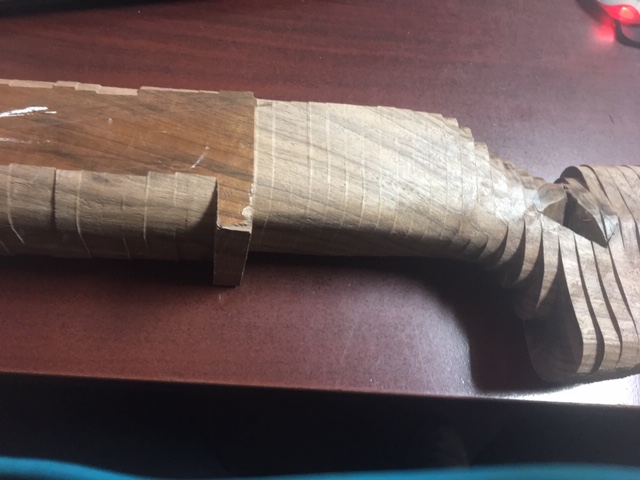

I have a figured walnut blank being milled/inletted/shaped for my action/barrel. Unfortunately when this was being done two large natural voids in the wood appeared. Nickel size or more near the wrist and below the cheek piece.

Could use West Epoxy and color it but considering using some of the extra wood to make a walnut circular plug/dowel and circular hole and match the grain direction. It is the same wood but from a different area so it cannot be a perfect match. I could inlet a square piece in after chiseling it for the same.

I may run an all thread rod up through the bottom where it would not be noticeable to strengthen the wrist.

As I already had it paid for on the inletting not much else I could do. If nothing more it will be a utility stock. Any thoughts or guidance is appreciated. Thanks

Could use West Epoxy and color it but considering using some of the extra wood to make a walnut circular plug/dowel and circular hole and match the grain direction. It is the same wood but from a different area so it cannot be a perfect match. I could inlet a square piece in after chiseling it for the same.

I may run an all thread rod up through the bottom where it would not be noticeable to strengthen the wrist.

As I already had it paid for on the inletting not much else I could do. If nothing more it will be a utility stock. Any thoughts or guidance is appreciated. Thanks