Based on actual experience, what do others find to be the optimum hunting and informal target sight setup, as far as peep and globe type sights are concerned?

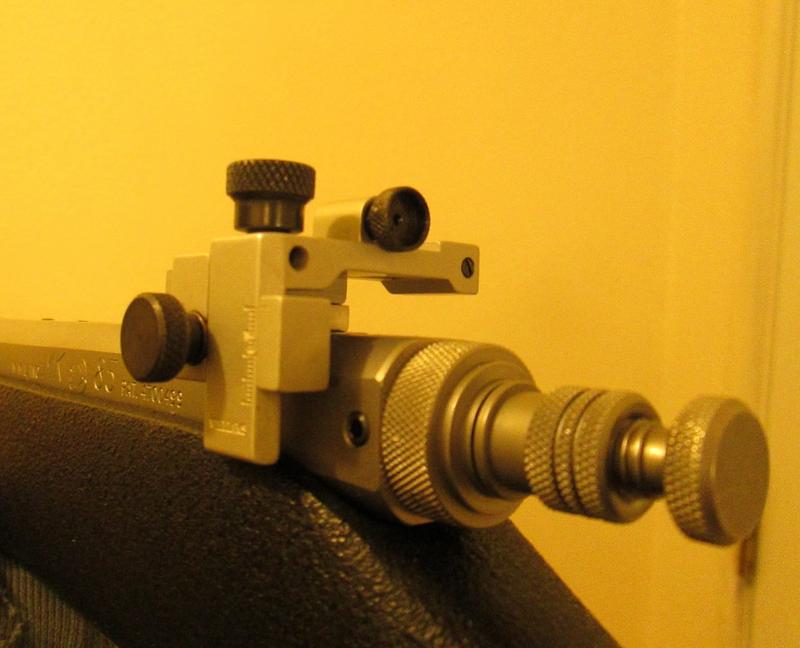

I currently have two TCs with 45 caliber LRH barrels sporting Lyman 57 SMLs on the rear and Lyman 17AML front sights using Lee Shavers inserts. fairly common, I guess. Have two MK85s that I am looking to set up with peep sights at some point in the future. Whatever I do, would like have all four setup pretty similar, but not sure that is possible.

Rambling rear sight question. Stay with the Lyman 57 or go to the Williams 1340 on the sidelocks? I have no experience with the Williams sight. With the MKs, I believe they would use either the Williams 44540 or Lyman 66MK (looks to be discontinued), any preferences? Does anyone see any real advantage to the Williams over the Lyman peep sight in general? Both Lyman and Williams appear to have 'quick adjust knobs' available. Don't see need for quick windage adjustment, and imagine any quick adjustment knob would get in the way on a sidelock (have already slightly bent the hammers to better clear the 57). On the 57 I just use the push button release to quick adjust. On that topic, the movable scale on the 57 allows zeroing out, while the Williams appears to have a set scale. Is one sight more durable than the other?

Front sight question. Is it worth the money for the Shaver 17A with the level when compared to the 17AML? Have a level on a bow sight and find it a distraction while target shooting, but can not say I have even looked at the level while hunting. Also thinking about the Lyman 17AHB that is .404” high (the shortest Shavers that I have seen is .500”). Would allow me to lower the rear sight (I use a steel shim to raise the rear sight base as much as possible to keep the rear sight extended as little as possible, plus allows maximum elevation adjustment.

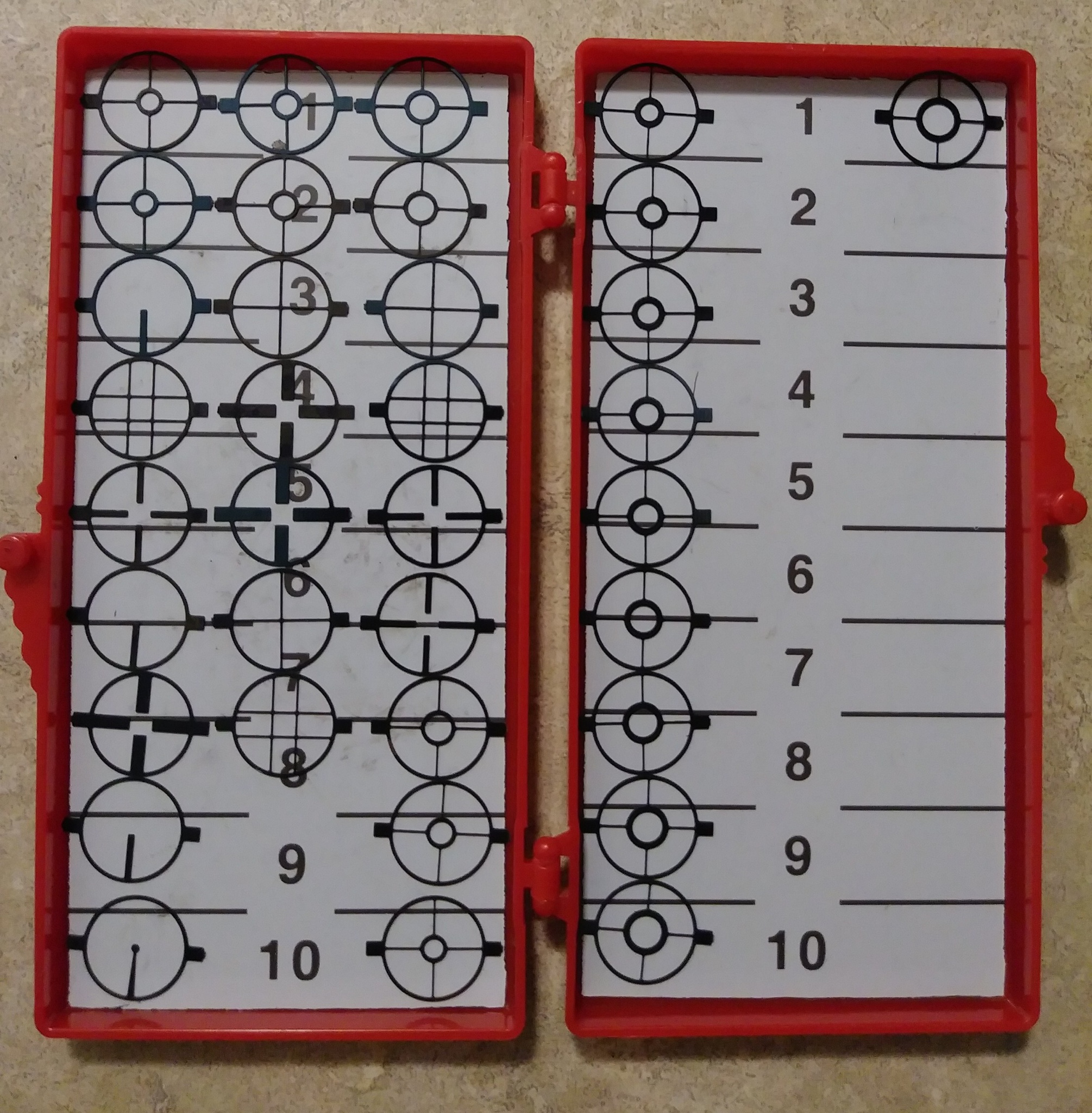

Don’t want this to be a Ford Chevy thing, just trying to understand if anyone has any real reasons for picking one sight over the other based on what they have experienced. Realistically, don’t see myself ever shooting over 150 yards at unwounded game with a muzzleloader using iron sights, however, with paper or steel, it comes down to how far I can see and adjust for.

I currently have two TCs with 45 caliber LRH barrels sporting Lyman 57 SMLs on the rear and Lyman 17AML front sights using Lee Shavers inserts. fairly common, I guess. Have two MK85s that I am looking to set up with peep sights at some point in the future. Whatever I do, would like have all four setup pretty similar, but not sure that is possible.

Rambling rear sight question. Stay with the Lyman 57 or go to the Williams 1340 on the sidelocks? I have no experience with the Williams sight. With the MKs, I believe they would use either the Williams 44540 or Lyman 66MK (looks to be discontinued), any preferences? Does anyone see any real advantage to the Williams over the Lyman peep sight in general? Both Lyman and Williams appear to have 'quick adjust knobs' available. Don't see need for quick windage adjustment, and imagine any quick adjustment knob would get in the way on a sidelock (have already slightly bent the hammers to better clear the 57). On the 57 I just use the push button release to quick adjust. On that topic, the movable scale on the 57 allows zeroing out, while the Williams appears to have a set scale. Is one sight more durable than the other?

Front sight question. Is it worth the money for the Shaver 17A with the level when compared to the 17AML? Have a level on a bow sight and find it a distraction while target shooting, but can not say I have even looked at the level while hunting. Also thinking about the Lyman 17AHB that is .404” high (the shortest Shavers that I have seen is .500”). Would allow me to lower the rear sight (I use a steel shim to raise the rear sight base as much as possible to keep the rear sight extended as little as possible, plus allows maximum elevation adjustment.

Don’t want this to be a Ford Chevy thing, just trying to understand if anyone has any real reasons for picking one sight over the other based on what they have experienced. Realistically, don’t see myself ever shooting over 150 yards at unwounded game with a muzzleloader using iron sights, however, with paper or steel, it comes down to how far I can see and adjust for.