To get the bolt apart (remove the hammer assembly from the bolt handle and housing) you will a 'C' tool as Busta suggested or properly insert a 7/16" open end wrench under the Secondary Safety of the bolt. The opening in the wrench 'does' need to be oriented in the right place to allow the Secondary Safety the ability to pull the hammer assembly back.

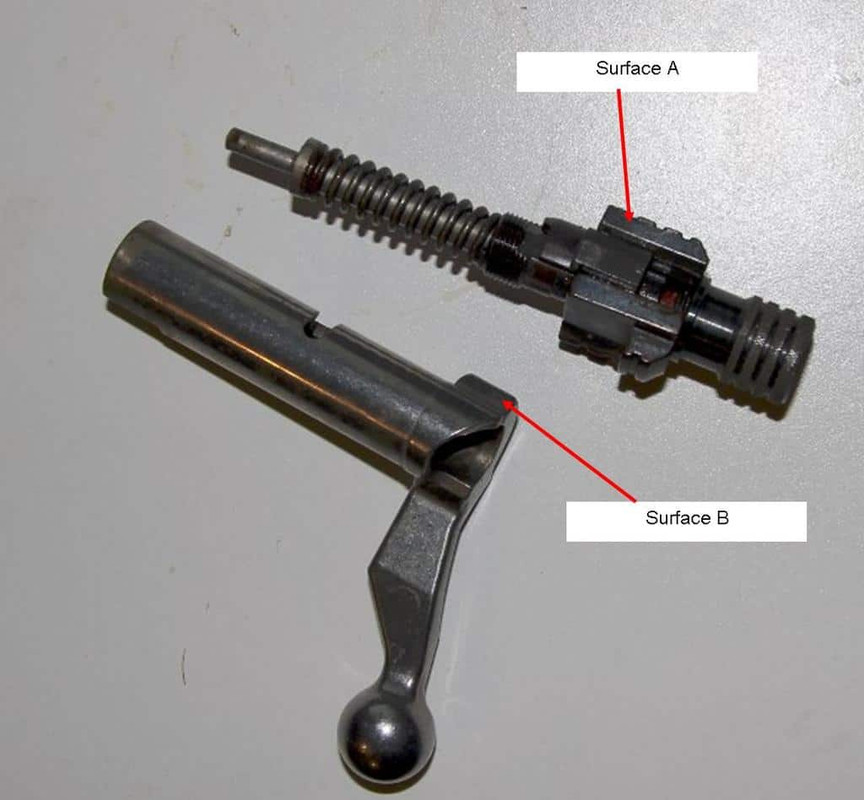

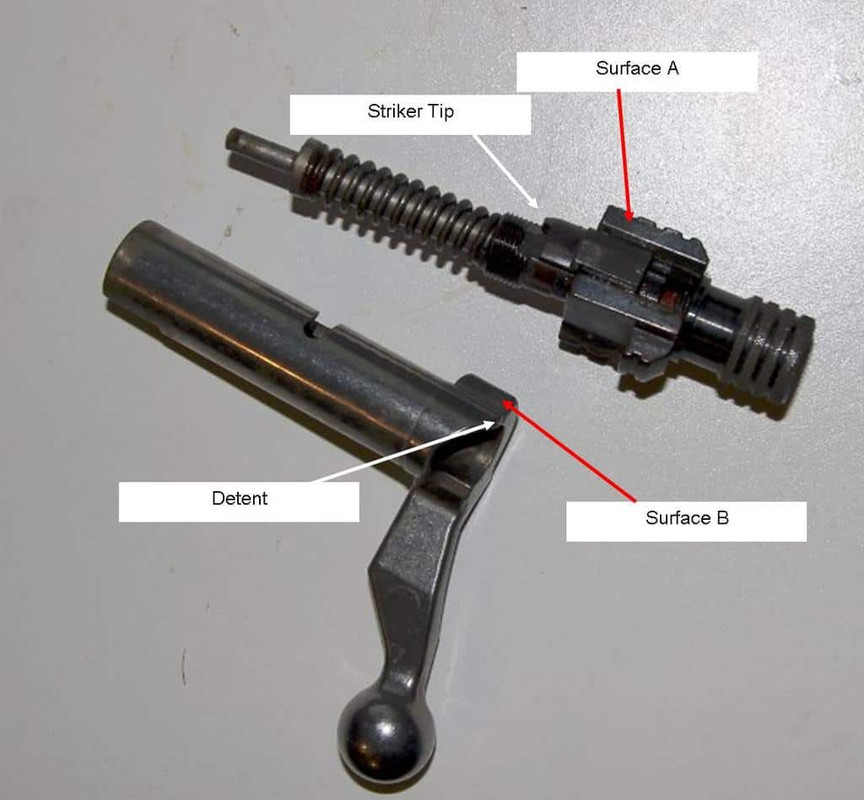

This picture might help some.

These pictures should help you orient the hammer assembly back into the bolt housing.

At some point you probably are going to want to change the bolt housing to the newer bolt housing that will allow you to use either the Red Plastic Jackets (FPJ) and 209 primer for ignition or the bare primer ignition (NFPJ) system. The problem will be finding a the newer bolt housing.

This picture shows the two different bolts... The bolt on top is a newer bolt for using either the FPJ or the NFPJ system. The upper bolt is pictured with a primer adapter installed for the bare primer ignition. The bolt on the bottom is the older Knight bolt for the Orange plastic jacket ignition

The rifle should/can shoot both sabots and conicals, but since you are in Colorado you are required to use full bore conicals. There are a few options available to you.

The one that I use here in Idaho is the Bull Shop .503x460NexMT lead conical

Sure hope some of this information helps...