- Joined

- Nov 28, 2015

- Messages

- 72

- Reaction score

- 0

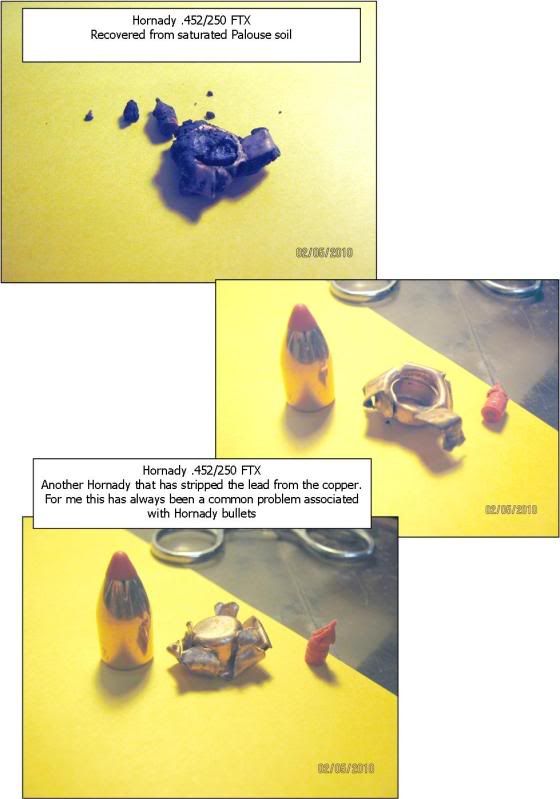

just did bare 209 conversion on .52 disc extreme...after about 10-15 shots primers were sticking in bolt face so bad I had to pull the bolt out every time. Load is .458 325gr FTX, 140gr BH209, win209 primer. Primers were bulged out (over pressured) but only at the end when they started sticking. First 10 or so looked fine and came out fine. Brand new breech plug shouldn't have opened up that quick I wouldn't think. I know that load seems a bit hot but it's one holing at 100yrds with it