Some might want to go back and read the original post? He said he would like to try the o-ring method with CCI 209M primers. Why not let him come to his own conclusion? I was merely trying to help him in his quest.

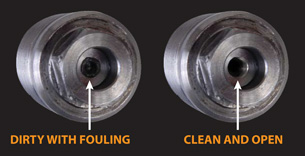

The only precautionary measure that needs to be considered, is getting fitment right with just primers before even considering loading the rifle.

I've been using o-rings in several breech plugs for 10 years now. Even kept it a secret for 6 months testing Blackhorn 209 in several rifles and breech plugs, before giving the idea away. They work great in a tip-up (break open) rifle that has the headspace to allow it. I've even modified several breech plugs primer pockets to accommodate them.

I have also experimented with them in the bolt action Knights back in 2008-2009. They can be made to work in those, however the camming action of the rotating bolt has to be taken into consideration. The headspace needs to be perfect, or the primer will turn the o-ring out when opening the bolt. Static shims work better in that application because of the leverage the rotating bolt and camming action provide. Either way, it still needs to be headspaced.

Good luck to the original poster. I hope you find what you are looking for! If you have any questions, just ask here, or send me a PM.

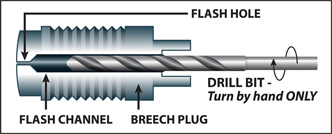

I will say, if you are intending on shooting Blackhorn 209, you will want a Blackhorn 209 breech plug (either CVA or Western Powders), or have your current OEM plug modified with a larger diameter flame channel, vent liner, and powder pocket.

Here is a refresher on the original post for those that may need it.

Bluedevil said:

Hey guys!

I finally got ahold of some rubber o-rings from McMaster-Carr in the size of 1x4.5 (buna).

I would like to try the rubber o-ring method for my CVA Accura V2 QRBP I was just wondering how many o-rings would it approximately take to achieve 0 headspace/primer crush using CCI 209M shotshell primers? I don’t have my muzzleloader with me so I can’t try it out till the weekend but was looking for an estimate. Thanks again!