Lewis, your subject matter expertise on this subject is priceless, be it shooting or casting. I am about to try my hand at the casting thing after my elk hunt next week, and I feel confident I will shave off lots of trial & error and time with your tips.

It's funny, I was out shooting yesterday trying to dial in a consistent, tight 100 yard group with my GPR Signature 54 with a patched ball. I wanted to take that with me hunting next week, but I couldn't for the life of me get a consistent 100yd group. I'd get two close together, then the third would be on the other side of the target. I was trying to keep everything consistent, patch, lube, swab between shots, balls were weighed, etc.

The only inconsistency I could think of, after I got home frustrated, was my powder charge. I remembered your videos and how you said you always weigh your powder charges vs. using a volumetric measuring device, which I had been using since I started down this black powder rabbit hole only a few short months ago.

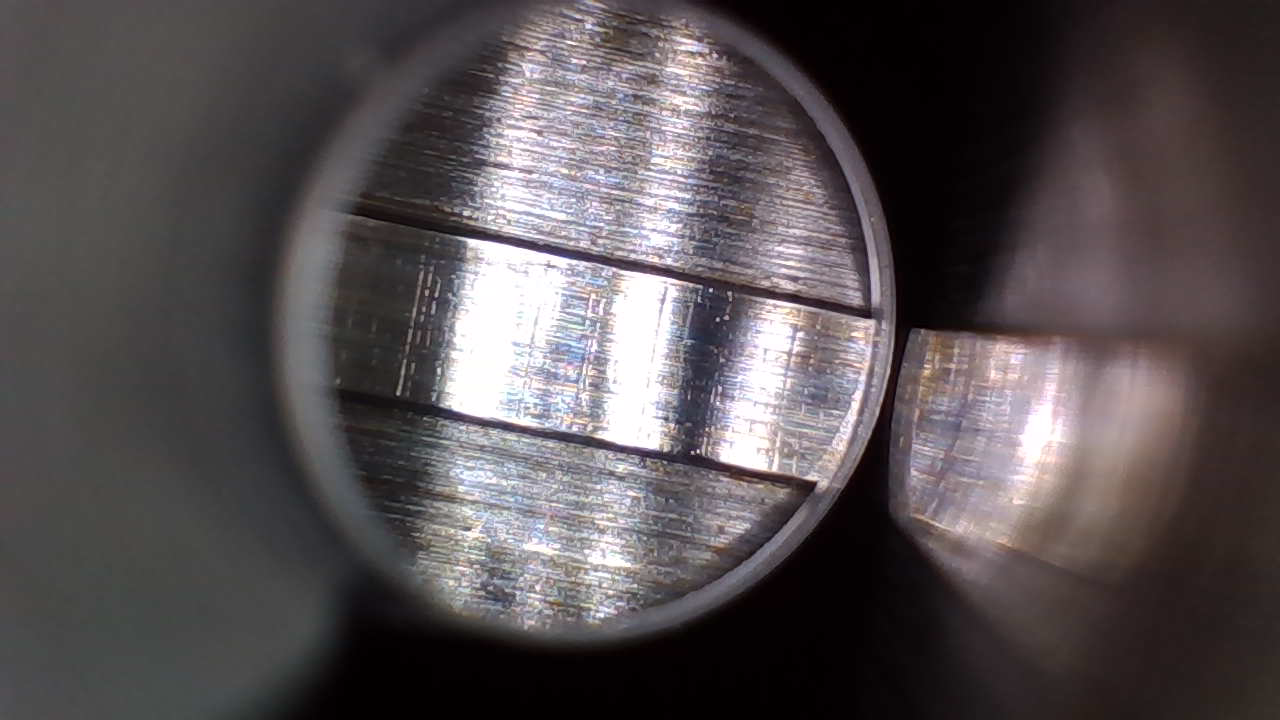

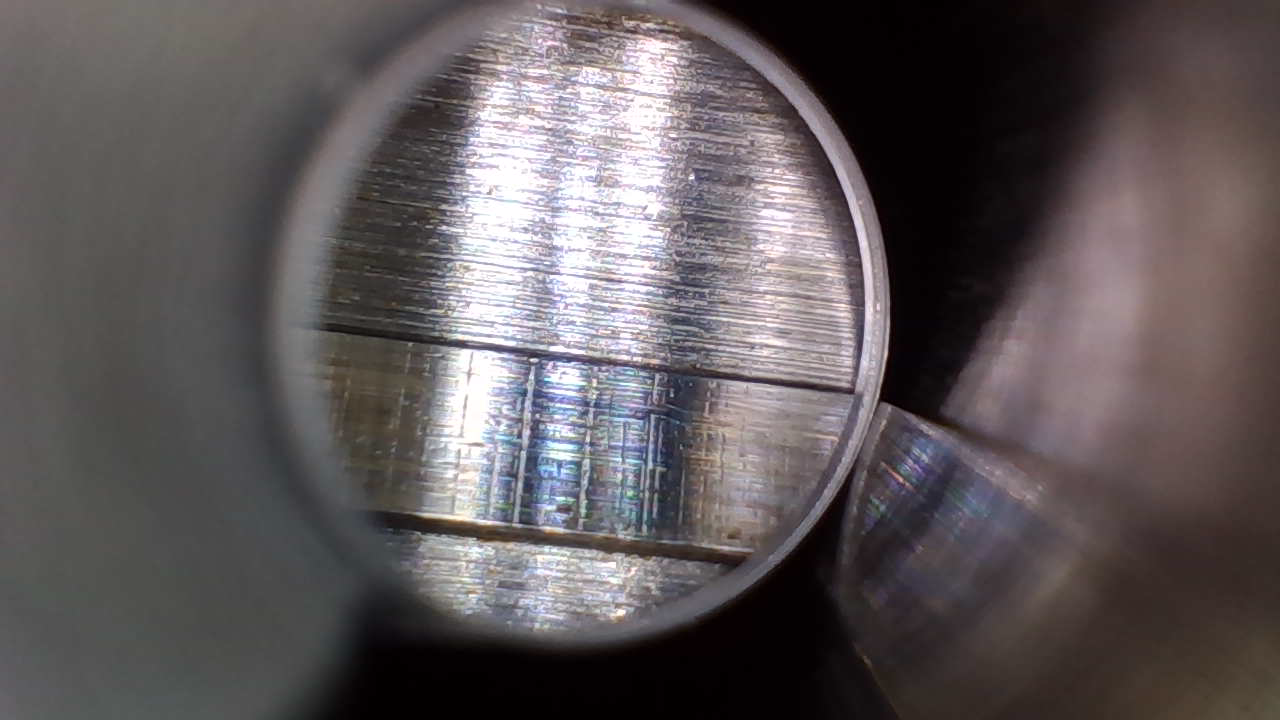

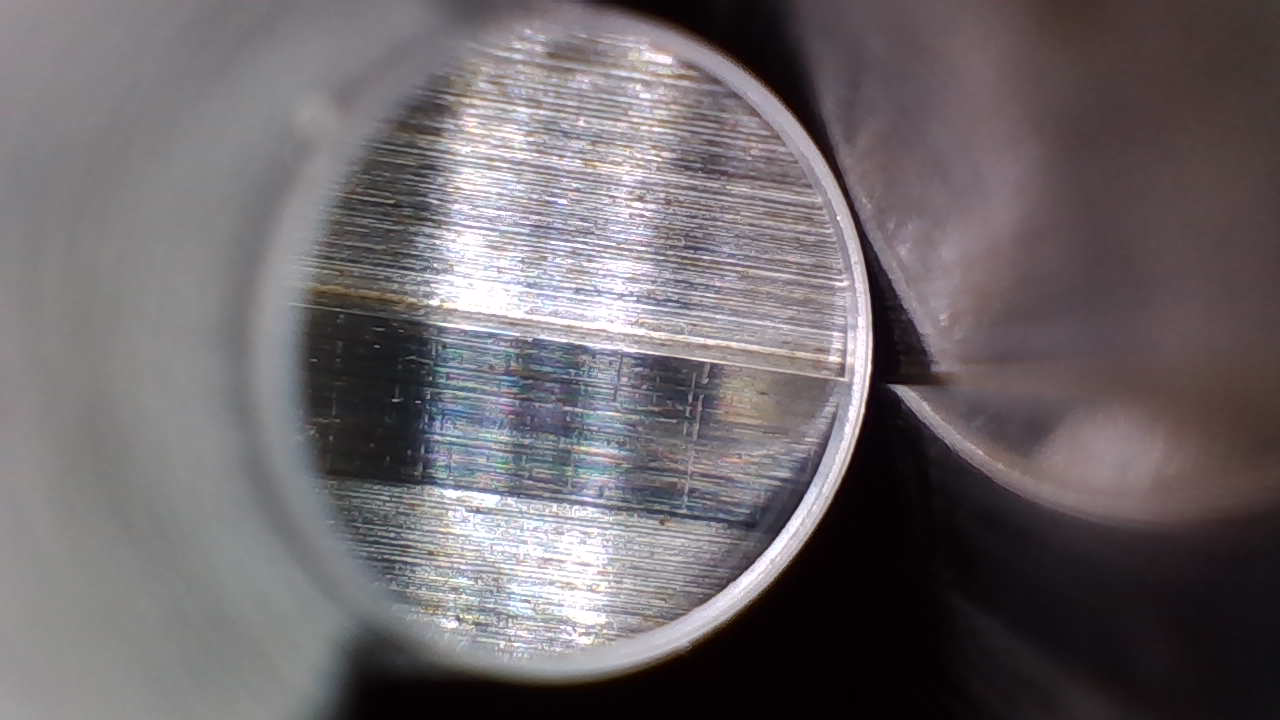

So, this morning I got out my digi scale to run some powder charges that I had been putting through the rifle using the brass powder measure.

What I thought was 100 grains by volume was actually 105-110+ grains (Swiss 2F), with that kind of spread in powder throws.

Unfortunately, I won't be able to get back out with some weighed charges to dial in a load with the 54 before my hunt. I will just use my scoped .270 this time. That took me a handful of rounds to get dialed in. Boring.

Again, thanks for all the knowledge you share here. It is appreciated by newbies like me.