And lastly but not leastly

If i had been using a Lube other My Own PROVEN Stuff (Which I’ve shared with all on here) My 5 Shot Group Target in this thread would VERY LIKELY NOT be what it is

Here is an AWESOME example of that. The ONLY thing Different here was the Bullet Lube. EVERYTHING else was identical, Believe me when i say that Bullet Lube can MAKE or BREAK accuracy, I have worked DILIGENTLY in this Stuff learning it. In short, i have made this Hobby my Life, I have lived and Breathed this Stuff for Several years now, Pretty much DAILY

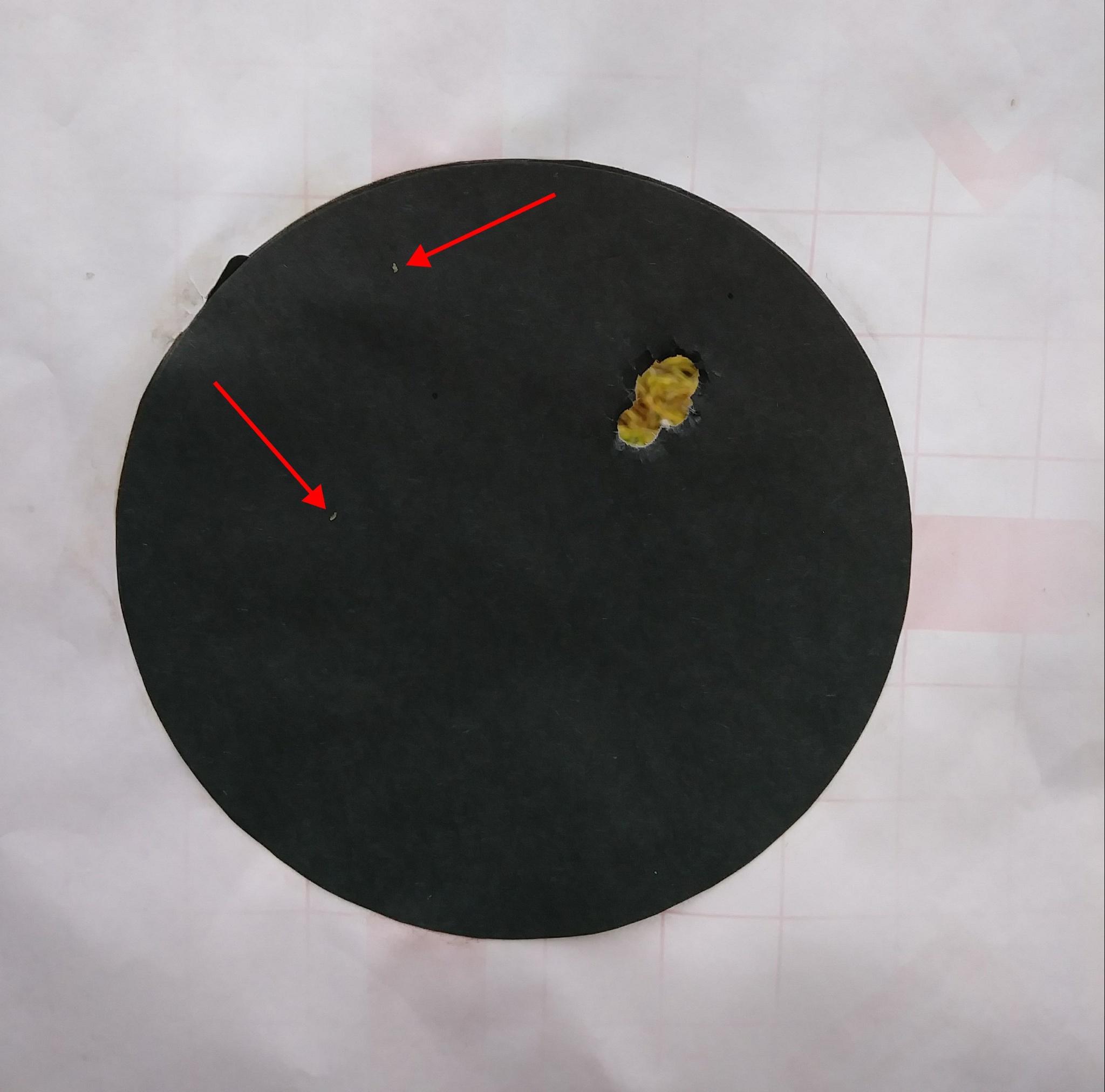

Remember, These Targets I’m gonna show were Shot BACK TO BACK, Same Bullet, Cast in the Same session, Same Powder Charges, and Wads, The

ONLY difference here was the Bullet Lube. This is 4 Shots with Lube “A” As you can see it wasn’t working well

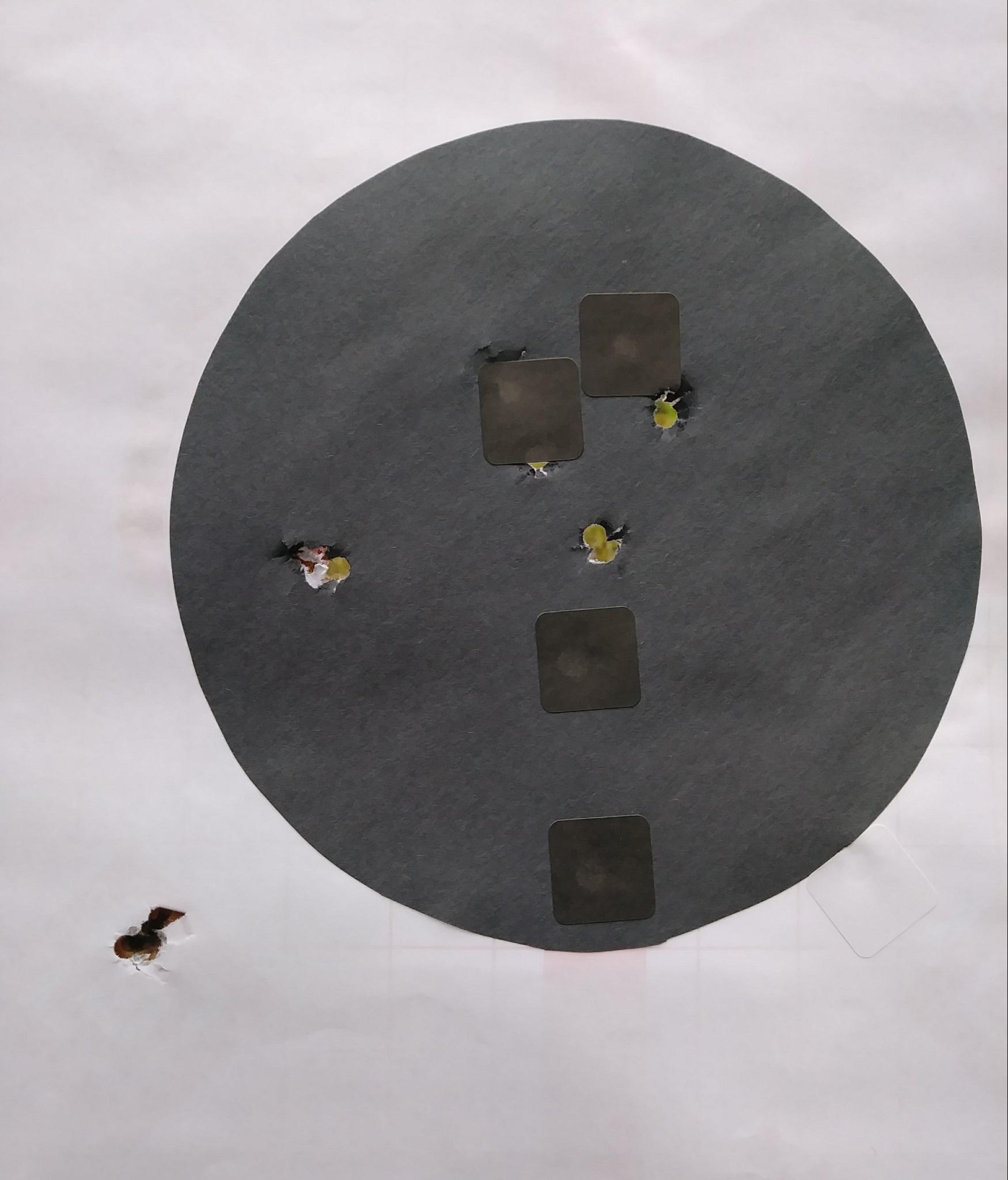

Now had i not “been here, Done that“ Before? I would have Given up on this Bullet Shooting in my Rifle, But i KNEW Better

And here is that EXACT SAME Bullet as above, Except Lubed with Lube “B” I have seen this several times over the last few years, this is probably the Best Example I’ve seen, The difference is usually not this WILD

Excess Lube in Grooves can be a BAD thing, Depending on the Lube? This is why you hear me speak of the importance of a “Soft Lube” The softer the Lube, the easier it is to “Shed away“ from the Bullet at the Muzzle upon exiting. You DEFINITELY want enough Lube, But excessive Lube sticking in the Grooves, Hitching a Ride to the Target can be Detrimental to Accuracy, I have seen it MANY MANY times. It doesn’t take as much Lube as one might think. And different lubes, Consistencies play a HUGE Role

Excess Lube in Grooves can be a BAD thing, Depending on the Lube? This is why you hear me speak of the importance of a “Soft Lube” The softer the Lube, the easier it is to “Shed away“ from the Bullet at the Muzzle upon exiting. You DEFINITELY want enough Lube, But excessive Lube sticking in the Grooves, Hitching a Ride to the Target can be Detrimental to Accuracy, I have seen it MANY MANY times. It doesn’t take as much Lube as one might think. And different lubes, Consistencies play a HUGE Role