- Joined

- Jan 11, 2019

- Messages

- 638

- Reaction score

- 171

It is an easy, straight forward process. First thing, is the Tang on your Rifle Drilled and Tapped for a Peep? TC Made some of Both, Some Tangs came Tapped for a Peep from the Factory, and Some Did not, out of my MANY Renegades and Hawkens only 1 of mine was Factory Drilled and Tapped, all of my others Required me to do it.

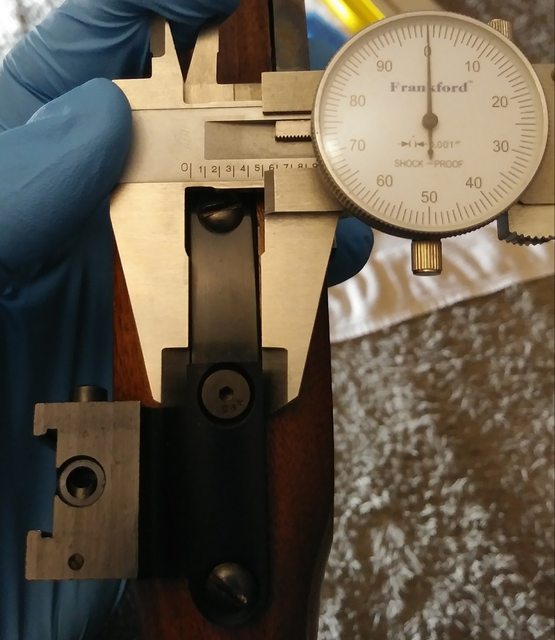

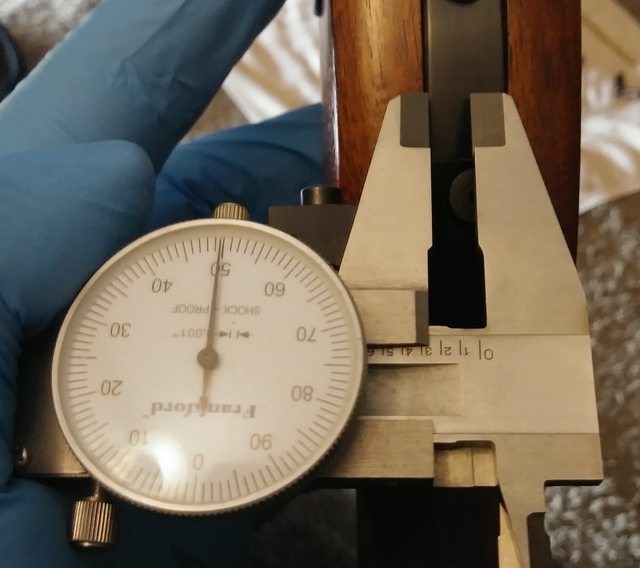

Not Drilled and Tapped for Peep. If your Tang is like this one you will need to Drill and Tap it to 8-32

Factory Drilled and Tapped for a Peep, they added a Plug to protect the Threads. Some Hawken’s and Renegades came this way, and Some didn’t, It has been my finding that more didn’t

The Lyman 57 Base will need to be Modified so that it Clears the Forward Wrist Wood of the Renegade.

It will look like this when you are done with it, i use a Dremel with a Sanding Wheel, takes about 2 minutes to do this. You can paint this black, or ignore it, it is Aluminum therefore will not Rust and this is Hidden as you will see below

Here you can See how well it Clears the Forward Wrist Wood of this Renegade after the above Mod.

This is a FUZZY Picture of a Lyman 57 on 1 of my Hawkens, i did not have to do the Above sight base Mod on this Rifle, it Cleared after i added the Required Front Washers to take out the “Forward Tilt” here you can see the Corner that needs to be Removed from the Sight Base for Renegade installation. The Hawkens are a Bit thinner Through the Wrist of the Stock than the Renegades, Some Hawkens do not need the Sight Base Mod, But so far all Renegades i have worked with do, The Forward Wrist Wood of the Renegade’s are a Bit Thicker.

See the Corner on the underside of the 57 Sight Base i am Talking about here? Look between this pic and the 1 above

Not Drilled and Tapped for Peep. If your Tang is like this one you will need to Drill and Tap it to 8-32

Factory Drilled and Tapped for a Peep, they added a Plug to protect the Threads. Some Hawken’s and Renegades came this way, and Some didn’t, It has been my finding that more didn’t

The Lyman 57 Base will need to be Modified so that it Clears the Forward Wrist Wood of the Renegade.

It will look like this when you are done with it, i use a Dremel with a Sanding Wheel, takes about 2 minutes to do this. You can paint this black, or ignore it, it is Aluminum therefore will not Rust and this is Hidden as you will see below

Here you can See how well it Clears the Forward Wrist Wood of this Renegade after the above Mod.

This is a FUZZY Picture of a Lyman 57 on 1 of my Hawkens, i did not have to do the Above sight base Mod on this Rifle, it Cleared after i added the Required Front Washers to take out the “Forward Tilt” here you can see the Corner that needs to be Removed from the Sight Base for Renegade installation. The Hawkens are a Bit thinner Through the Wrist of the Stock than the Renegades, Some Hawkens do not need the Sight Base Mod, But so far all Renegades i have worked with do, The Forward Wrist Wood of the Renegade’s are a Bit Thicker.

See the Corner on the underside of the 57 Sight Base i am Talking about here? Look between this pic and the 1 above