Idaholewis

Well-Known Member

- Joined

- Jun 30, 2017

- Messages

- 7,287

- Reaction score

- 10,288

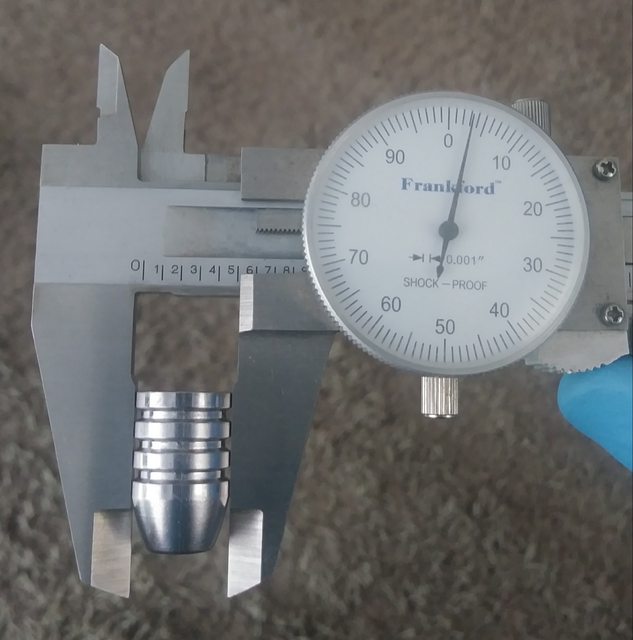

I cranked these out this Morning for a Friend, From my Accurate Molds #50-385M, Casted of BACO Certified PURE Lead. These ALL Weigh 399.5 to 400 Grains, 1/2 Grain of Eachother

Oxide Coating Cleaned up nicely

He needed .503, This Should do the Trick

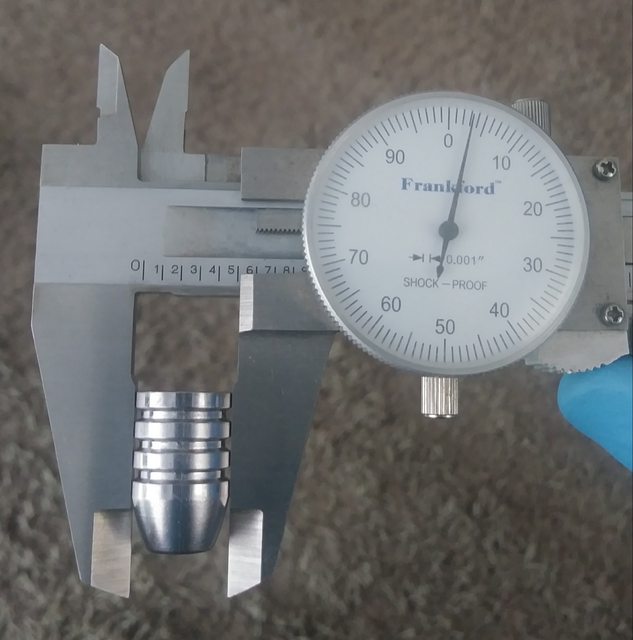

Oxide Coating Cleaned up nicely

He needed .503, This Should do the Trick