You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Breech plug question

- Thread starter ENCORE50A

- Start date

Help Support Modern Muzzleloading Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

- Joined

- Sep 23, 2010

- Messages

- 13,946

- Reaction score

- 915

Saying someone has no clue when they're trying to help is an insult in my book.

Nobody in this thread has given you an answer to your question. Not one person torques the BP. So, i'm guessing you think nobody has a clue?

Nobody in this thread has given you an answer to your question. Not one person torques the BP. So, i'm guessing you think nobody has a clue?

- Joined

- Sep 23, 2010

- Messages

- 13,946

- Reaction score

- 915

lptroll said:your short answer is "no".

We should have all said that. It would have been easier.

- Joined

- May 17, 2005

- Messages

- 4,940

- Reaction score

- 146

bestill said:Imo manufactures don't usually give specs to mass sold rifles because of lack of knowledge of when a plug freely turns in and bottoms out compared to a poorly maintained rifle that has to be forced in because of carbon build up. Which would wreck torque specs..

.

I thought I said that in a different way. But I torque my plugs and after doing some research I'm probably in the wrong. Im probably torquing/tightening them to hard. A breech plug threaded in to a properly cleaned ML should go in finger tight and not torqued. That's my opinion and I would love to know or hear why that isn't correct.

- Joined

- Dec 4, 2009

- Messages

- 7,556

- Reaction score

- 8,217

Well, without much information available, one can only assume that in most cases, 80ip or 6.6# is most likely the maximum needed. I only base that off the torque relating to the Remington Ultimate, which is 80ip.

- Joined

- Nov 29, 2014

- Messages

- 1,362

- Reaction score

- 395

Grouse said:bestill said:Imo manufactures don't usually give specs to mass sold rifles because of lack of knowledge of when a plug freely turns in and bottoms out compared to a poorly maintained rifle that has to be forced in because of carbon build up. Which would wreck torque specs..

.

I thought I said that in a different way. But I torque my plugs and after doing some research I'm probably in the wrong. Im probably torquing/tightening them to hard. A breech plug threaded in to a properly cleaned ML should go in finger tight and not torqued. That's my opinion and I would love to know or hear why that isn't correct.

Your rite on but after threads are clear and plug screws in freely and bottoms out it still needs snugged up or torqued

- Joined

- Dec 26, 2010

- Messages

- 3,537

- Reaction score

- 1,490

Honestly, and I am by no means as experienced as you guys, but torquing seems unnecessary to me. I have been tightening my Knight DISC BPs with a socket wrench just snug, not torqued down hard. I also, since switching to BH209, have only been putting a few drops of CLP on the threads before installing and have never had a problem with a stuck or excessively fouled BP. No grease, no Teflon tape...nothing but drops of CLP. Comes out clean as a whistle and never hard to remove.

When I break down my rifles for cleaning the BP comes out very easy. I am shooting 100 grains of BH209. Minimal, if any, blow back due to switching to the Lehigh 209 conversion BP and adapter.

Isn't this torquing issue a bit of overkill?

When I break down my rifles for cleaning the BP comes out very easy. I am shooting 100 grains of BH209. Minimal, if any, blow back due to switching to the Lehigh 209 conversion BP and adapter.

Isn't this torquing issue a bit of overkill?

- Joined

- Dec 4, 2009

- Messages

- 7,556

- Reaction score

- 8,217

halloflin said:Honestly, and I am by no means as experienced as you guys, but torquing seems unnecessary to me. I have been tightening my Knight DISC BPs with a socket wrench just snug, not torqued down hard. I also, since switching to BH209, have only been putting a few drops of CLP on the threads before installing and have never had a problem with a stuck or excessively fouled BP. No grease, no Teflon tape...nothing but drops of CLP. Comes out clean as a whistle and never hard to remove.

When I break down my rifles for cleaning the BP comes out very easy. I am shooting 100 grains of BH209. Minimal, if any, blow back due to switching to the Lehigh 209 conversion BP and adapter.

Isn't this torquing issue a bit of overkill?

IMO its far from overkill. Is it absolutely necessary to know? Well for most, probably not because tight is tight, right? However is that the same for installing mounts and rings for a scope? We work on these rifles every day, well some do, but some of the technical stuff is never known by most. Take for instance, how much force do you use to seat a bullet/sabot? That question has come up before here, and we do know that in some cases, seating pressure matters.

I guess if one doesn't want to be technical about things, then this question wouldn't matter to them. On the other hand, for those who would like to know this information, is there a better place to ask?

- Joined

- Sep 23, 2010

- Messages

- 13,946

- Reaction score

- 915

Hopefully, you'll get to the part that it does matter, and show some proof. My mind is open to learn.

I'm talking about torque on the BP. Not the rest of what you just said.

I'm talking about torque on the BP. Not the rest of what you just said.

- Joined

- May 19, 2005

- Messages

- 9,205

- Reaction score

- 1,740

ENCORE50A said:Don't need to know what BP is better than the other............

I'm asking those who DO NOT use any type of QR BP (finger type).

Has anyone ever actually checked the torque when you tighten your breech plug?

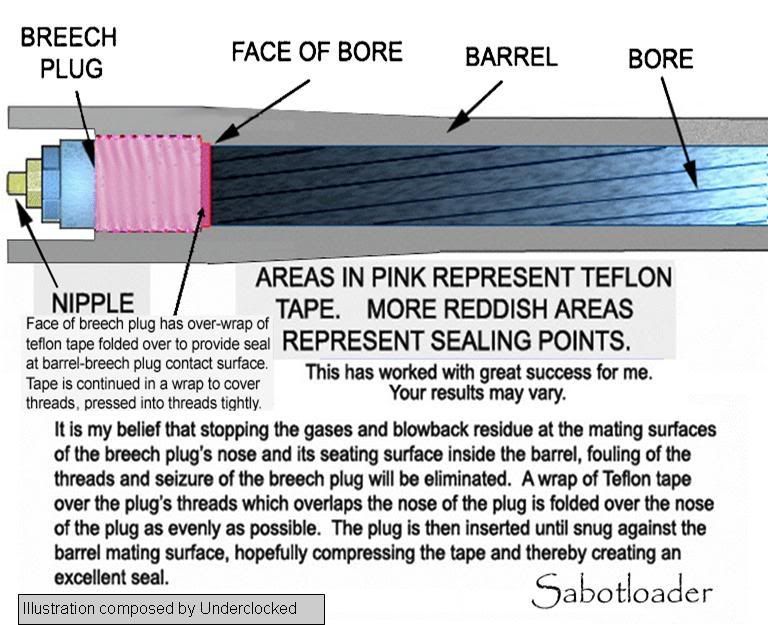

In all honesty - I can not tell you the amount of torgue that I use for the breech plug. For many years I tried different methds including backing off a bit or tightening just until the plug bottomed. Several years ago I changed my thoughts on this. It is my reasoning that the breech plug - barrel gas seal should occur when the nose of the breech plug meets the shelf in the barrel. If the nose is seal is formed there then the blow back gases will be stopped at that point. Threads will not be fouled and gas cutting of the threads will not occur. I shoot T7 so I need to be vigelent about this because at a range session I never loosen the plug.

This illustration completed by Underclocked attempts to show what I am trying to say.

I do use Teflon tape to help maintain the seal. I have never liked grease.

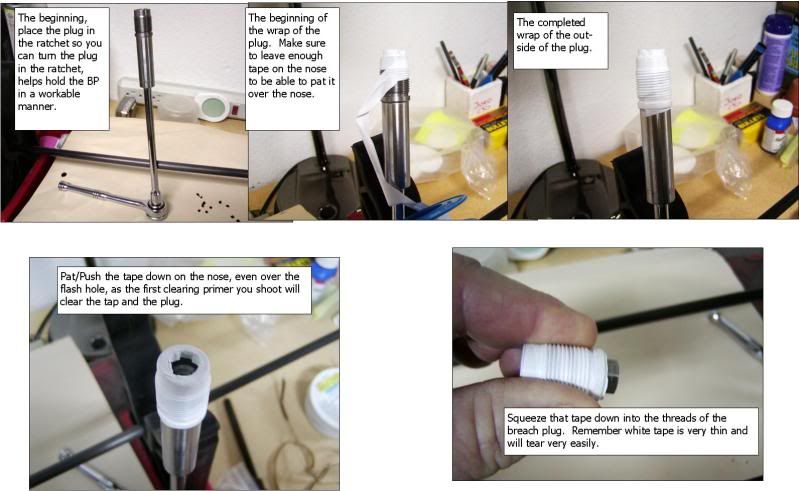

So I tape the plug as indicated in these pictures...

Then I install the plug in the rifle until it bottoms out. Then with the ratchet I apply and addition amount of pressure to squeeze the tape that has been placed over the nose to the shelf in the barrel. How many pounds I do not know but it is somewhat tight.

If I did my job correctly everything works as planned noting on the threads and the plug comes out with the ratchet again...

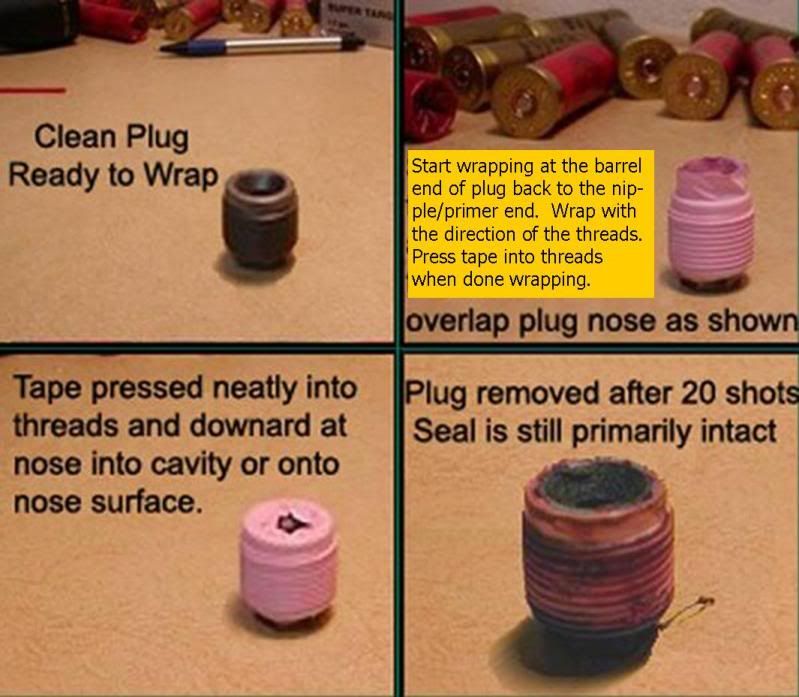

This set of pictures is a Remington plug wrapped in pink tape shot several times and removed. I should tell most often the white does not come out on the BP but stays in the threads of the barrel. A simple bronze brush rotated CCW bring the remains out.

So in all of this I can tell you the specific torque - it is feel I have developed over a lot of years. The plug is SNUG!

- Joined

- Dec 26, 2010

- Messages

- 3,537

- Reaction score

- 1,490

Absolutely a great place to ask. But for me, the average deer hunter, ML shooter, torquing isn't necessary. But for you technical guys I can see where it is a must. I would venture to guess that the majority of the members, visitors, here are average shooters so torquing would not be necessary.

Again, not trying to argue or disrespect anyone's opinion on perfection (torquing), just an observation.

Again, not trying to argue or disrespect anyone's opinion on perfection (torquing), just an observation.

- Joined

- Dec 4, 2009

- Messages

- 7,556

- Reaction score

- 8,217

Muley Hunter said:Hopefully, you'll get to the part that it does matter, and show some proof. My mind is open to learn.

I'm talking about torque on the BP. Not the rest of what you just said.

Well the Remington Ultimate is 80 inch pounds, which is 6.6 pounds. I'm going to hunt up a RU manual and verify that. It takes a thin wall socket to remove it through the action. 1/4" drive ratchet and a 12" extension to even get to it.

The UF rifles BP's are torqued to 80 inch pounds also with a thin walled 5/16 deep well. I own and shoot one, so that's easily verified. So far, the only data that I can muster up is related to heavy recoiling rifles, the RU and UF and both indicate a torque of 80 inch pounds (6.6 pounds).

- Joined

- Dec 4, 2009

- Messages

- 7,556

- Reaction score

- 8,217

Sabotloader..........

Great illustrations. I agree 100% with you about the breech face and meeting the barrel.

If the face and barrel matched perfectly, were completely clean of dirt, carbon, etc., what kind of torque would you think might be necessary, say for production rifles? Do you or can you check a rifle sometime just to see what you may torque the plug to?

Great illustrations. I agree 100% with you about the breech face and meeting the barrel.

If the face and barrel matched perfectly, were completely clean of dirt, carbon, etc., what kind of torque would you think might be necessary, say for production rifles? Do you or can you check a rifle sometime just to see what you may torque the plug to?

- Joined

- Sep 23, 2010

- Messages

- 13,946

- Reaction score

- 915

That's fine, but does that mean performance would be lost by torquing more lbs? That's also one gun. maybe it has tighter tolerances than the average production gun.

The reason I torqued mine more was to make sure it was sealed. It was an Omega. TC has a hard time making a straight QLA. Why would I trust the surface of the barrel and BP is perfect? It was just a little insurance. It wasn't because I didn't think it was important. I'm actually very picky about details. I've been into lots of competitions, and I got quite anal about details.

The reason I torqued mine more was to make sure it was sealed. It was an Omega. TC has a hard time making a straight QLA. Why would I trust the surface of the barrel and BP is perfect? It was just a little insurance. It wasn't because I didn't think it was important. I'm actually very picky about details. I've been into lots of competitions, and I got quite anal about details.

That specification could be a purely arbitrary value. Deeper discussion would have to take place with that engineering team as to why that is their specified torque application. They would know their calculation imputs as well as their component requirement.

Are those Ultimate BP's designed NOT to be removed and reinstalled by the user? They are set at that specification at manufacture?

Are those Ultimate BP's designed NOT to be removed and reinstalled by the user? They are set at that specification at manufacture?

- Joined

- Dec 4, 2009

- Messages

- 7,556

- Reaction score

- 8,217

Muley Hunter said:That's fine, but does that mean performance would be lost by torquing more lbs? That's also one gun. maybe it has tighter tolerances than the average production gun.

The reason I torqued mine more was to make sure it was sealed. It was an Omega. TC has a hard time making a straight QLA. Why would I trust the surface of the barrel and BP is perfect? It was just a little insurance. It wasn't because I didn't think it was important. I'm actually very picky about details. I've been into lots of competitions, and I got quite anal about details.

In a perfect world, the face of the BP meeting the flat of the barrel would create the perfect seal. There are always things called contributing factors. Some BP's may require tape to seal. Others may require a washer or O ring.

Ron just tested one of his rifles breech plugs (reported elsewhere) He reported he checked it multiple times and indicates his normal torque procedure is about 38 inch pounds.

- Joined

- Sep 23, 2010

- Messages

- 13,946

- Reaction score

- 915

I used to be a powerlifter. 30lbs seemed light to me.

- Joined

- Dec 4, 2009

- Messages

- 7,556

- Reaction score

- 8,217

WTM45 said:That specification could be a purely arbitrary value. Deeper discussion would have to take place with that engineering team as to why that is their specified torque application. They would know their calculation imputs as well as their component requirement.

Are those Ultimate BP's designed NOT to be removed and reinstalled by the user? They are set at that specification at manufacture?

UF does not want the owner removing his breech plug but, it can be removed. I believe the reasoning behind it, may be that they don't want people messing up the threads. Remington who purchased the rights to the same breech plug, states that it doesn't need to be removed, yet it can be removed if the owner so chooses. Both Remington and UF set the specifications, based on extensive testing. Remington followed UF.

However to remove the BP's, if one shoots them using just grease or BP grease, they will most likely not get them out. Remington recommends using anti-seize and somewhere there's a product number. I would suggest that normal anti-seize not be used, nor that which contains copper. Permatex has a anti-seize called Nickel. Its made for extreme pressures and temps up to 2,400 degrees F. Its specific use is for stainless steel, titanium and nickel.

Similar threads

- Replies

- 25

- Views

- 2K

- Replies

- 0

- Views

- 112

- Replies

- 19

- Views

- 2K

- Replies

- 4

- Views

- 915