Got out this afternoon to shoot the Huntsman with the Hubbard 209 Breech plug and Blackhorn 209 powder. It worked flawlessly, perfect ignition everytime. I shot saboted bullets, White Power Punch Conicals, and the NEW Hornady FPB. I have been waiting for a plug like this for over 5 years, and I really like the results. All shots were with the Hubbard 209 breech plug today.

Group 1 (center bull, Pic #1) for the day was T/C 240 gr Cheapshots, 80 gr BH209, Win W209 Primers. The group was a vertical string and measured 1.255".

Pic #1

Group 2 (lower right bull, Pic #1) was Hornady 300 gr .452 XTP/MAG, 80 gr BH209, Red Harvester Crush Rib Sabots (for smokeless muzzleloaders), 80 gr BH209, Win W209 Primers. This group measured 1.901"

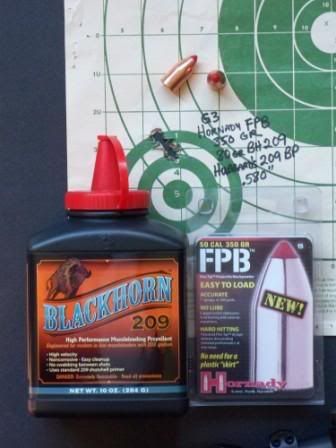

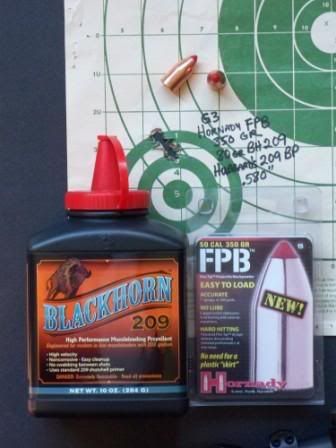

Group 3 (lower left bull, Pic #1 and Pic #2) was the NEW Hornady 350 gr FPB. To my surprise, this bullet loaded flawlessly, ignition was perfect, and accuracy was exceptional. This group measured .580", what a great shooting bullet. Look out PowerBelt, this bullet is for real.

Pic #2

Group 4 (upper left bull, Pic #1) was the Knight/Barnes 250 gr PBT with the NEW Blue EZ Load Sabots, 80 gr BH209, and Win W209 Primers. The group measured at 1.373". These sabots load WAY to easy in the .502 NEF Bore, but surprisingly I had instant ignition every time.

Group 5 (upper right bull, Pic #1) was the Hornady 300 gr SST, 80 gr BH209, CCI 209 Primers. The first two were touching, but pulled the third to the right making for a 1.340" horizontal group.

Since the Hornady FPB's worked so well I deceided to try out some all lead conicals. I pulled out some White 440 grain Power Punch Bullets, two .060" x .518" fiber gasket wads, 70 grains BH209, CCI Primers. All loads fired perfectly, absolutely no hang/delayed fires today and the best group of the day at .552". I truely was shocked at the results, the conicals outshot the saboted bullets, and I deceided to quit while I was ahead. Still grinnin'.

Group 1 (center bull, Pic #1) for the day was T/C 240 gr Cheapshots, 80 gr BH209, Win W209 Primers. The group was a vertical string and measured 1.255".

Pic #1

Group 2 (lower right bull, Pic #1) was Hornady 300 gr .452 XTP/MAG, 80 gr BH209, Red Harvester Crush Rib Sabots (for smokeless muzzleloaders), 80 gr BH209, Win W209 Primers. This group measured 1.901"

Group 3 (lower left bull, Pic #1 and Pic #2) was the NEW Hornady 350 gr FPB. To my surprise, this bullet loaded flawlessly, ignition was perfect, and accuracy was exceptional. This group measured .580", what a great shooting bullet. Look out PowerBelt, this bullet is for real.

Pic #2

Group 4 (upper left bull, Pic #1) was the Knight/Barnes 250 gr PBT with the NEW Blue EZ Load Sabots, 80 gr BH209, and Win W209 Primers. The group measured at 1.373". These sabots load WAY to easy in the .502 NEF Bore, but surprisingly I had instant ignition every time.

Group 5 (upper right bull, Pic #1) was the Hornady 300 gr SST, 80 gr BH209, CCI 209 Primers. The first two were touching, but pulled the third to the right making for a 1.340" horizontal group.

Since the Hornady FPB's worked so well I deceided to try out some all lead conicals. I pulled out some White 440 grain Power Punch Bullets, two .060" x .518" fiber gasket wads, 70 grains BH209, CCI Primers. All loads fired perfectly, absolutely no hang/delayed fires today and the best group of the day at .552". I truely was shocked at the results, the conicals outshot the saboted bullets, and I deceided to quit while I was ahead. Still grinnin'.