Idaholewis

Well-Known Member

- Joined

- Jun 30, 2017

- Messages

- 7,287

- Reaction score

- 10,288

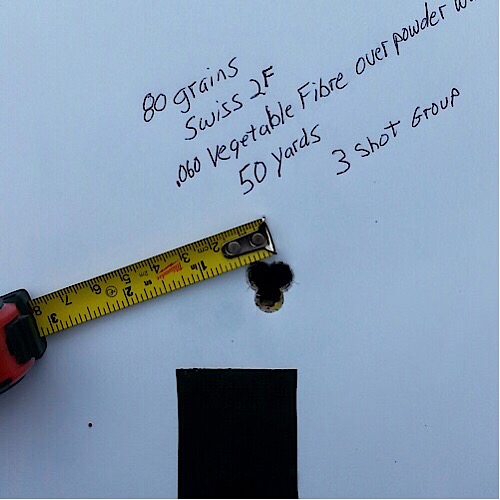

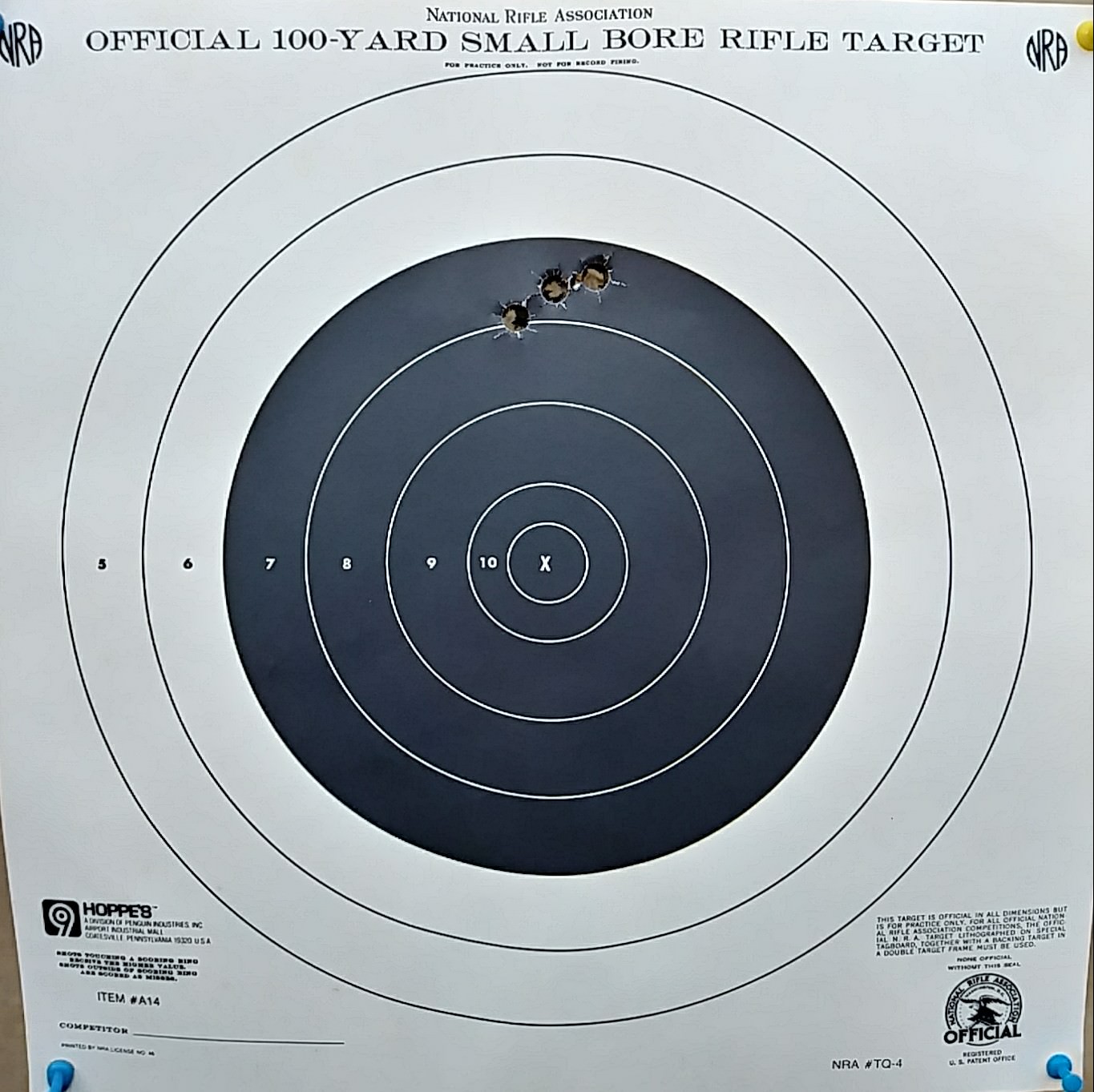

I just shot my big wide Meplat .45 Cal PP bullet at my 100 yard range, I wish i could say i shot the 2 shots to the right, made a sight adjustment and shot the other 3, But that’s NOT how it went. I have something odd going on? I am either changing my sight picture somehow, or something is shifting/moving? My first shot was the highest above the Center of the X, My next 2 shots were together just under an inch apart but far right, i went back and shot my last 2 and they ended up with my first shot? ODD?

My Target

Same 100 yard Range, Target on far bank

And the Bullet, These are Pure lead. They drop from my mold at around .443, and Wrap up to .450-.451, i run them through my .449 sizer (hardly any resistance felt) They ‘bounce back’ at .450, They load REALLY nice in my .45 Cal Green Mountain LRH 1:30 Twist, i would trust these bullets to stay put on the powder, The Papers ‘Shuck’ from the bullets perfectly upon exiting the bore and are found within 10 feet or so of the Muzzle

My Target

Same 100 yard Range, Target on far bank

And the Bullet, These are Pure lead. They drop from my mold at around .443, and Wrap up to .450-.451, i run them through my .449 sizer (hardly any resistance felt) They ‘bounce back’ at .450, They load REALLY nice in my .45 Cal Green Mountain LRH 1:30 Twist, i would trust these bullets to stay put on the powder, The Papers ‘Shuck’ from the bullets perfectly upon exiting the bore and are found within 10 feet or so of the Muzzle