Idaholewis

Well-Known Member

- Joined

- Jun 30, 2017

- Messages

- 7,287

- Reaction score

- 10,288

I ordered these 2 Molds the 17th or 18th, They arrived this morning, Talk about FAST!!

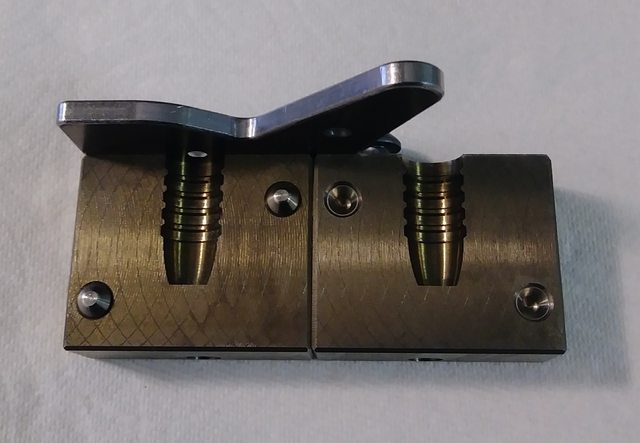

As I mentioned in a Previous thread These are “Revised” Versions of 2 Molds I have. I swear by Steel Bullet Molds. NO MORE Aluminum Bullet Molds for me!! Aluminum Molds were the Worst Decision i made in Casting. Luckily I Only have a Few to live with

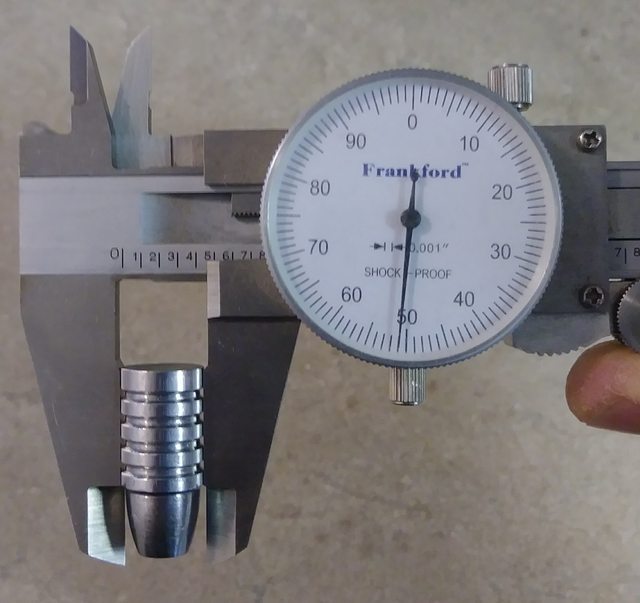

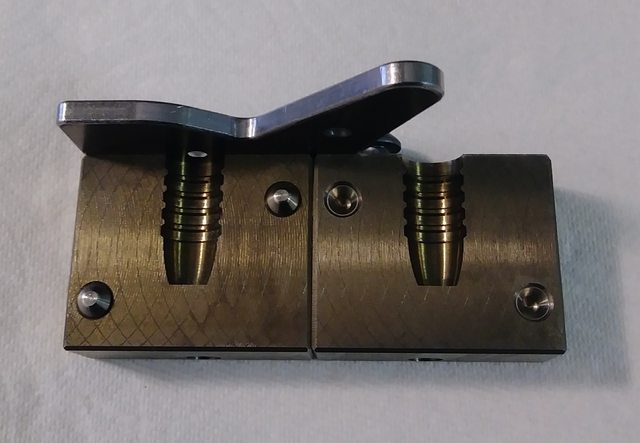

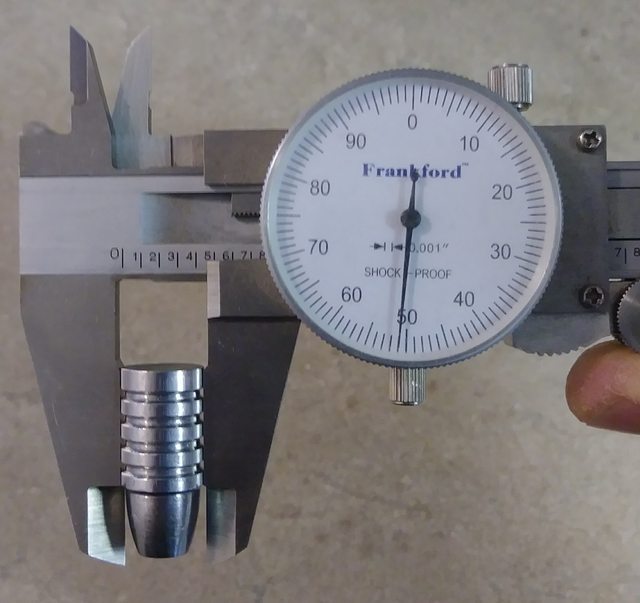

Here is the .45 Cal, It is Accurate Molds #46-380M, Typical AWESOME Mold From Accurate I Did AWAY with the Bevel Base, and Taper, The Bullet Drops at .454

I Did AWAY with the Bevel Base, and Taper, The Bullet Drops at .454

Weight is 385.5-386 Grains PURE LEAD

A quick, and EFFORTLESS trip through my .451 Sizer, These are Ready for testing

As I mentioned in a Previous thread These are “Revised” Versions of 2 Molds I have. I swear by Steel Bullet Molds. NO MORE Aluminum Bullet Molds for me!! Aluminum Molds were the Worst Decision i made in Casting. Luckily I Only have a Few to live with

Here is the .45 Cal, It is Accurate Molds #46-380M, Typical AWESOME Mold From Accurate

I Did AWAY with the Bevel Base, and Taper, The Bullet Drops at .454

I Did AWAY with the Bevel Base, and Taper, The Bullet Drops at .454

Weight is 385.5-386 Grains PURE LEAD

A quick, and EFFORTLESS trip through my .451 Sizer, These are Ready for testing