ShawnT said:

Sabotloader,

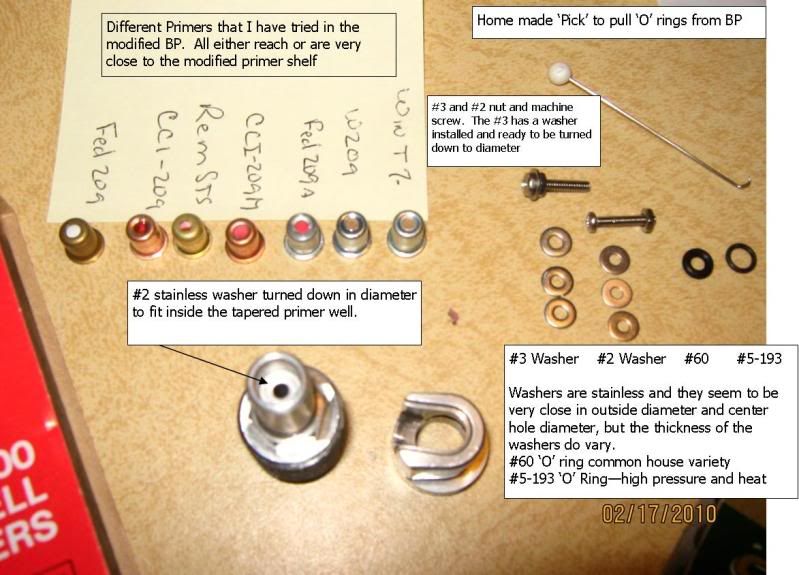

How thick is the #5-193 o-ring, and where did you get them? The smallest the hardware store I went to had was the #60. I did not see it by that number at McMaster Carr either. I cut one of the #60's (.067 thick)in half with a razor knife and it was still too thick, it was .033. I think that (just guessing here) that the Win209 is within .010 of bottoming out and maybe less. I am going to try play with that some more.

It measures about 0.050 so it sound to thick also although it has a larger diameter center so the nose of the primer actually pressing down into the donut hole a bit..

I would think McMaster Carr should certainly have it.. i just did an internet search for 5-193 O ring and came up with some options... might try that.

The other thing PM

jsteurrys1 he is a engineer that put me on to them he gets them all the time.

Found them here they are:

http://www1.mscdirect.com/CGI/GSDRVSM?P ... 0167048331

That was not a good reference - might call them and see what they say - but i would fire a PM to jsterrys1 - tell him I sent you.

And in your case the vari-flames might be a legitimate answer as they are longer than w209's

Do you think that the length would be of help, or would the reduced power of the small rifle primer be of more help? I know you would have to be careful removing the adapter. The way it is now if you pull back quick on the spur for the rolling block it will pretty much pitch the primer out of the action as if it has an ejector. [/quote]

I do I think they might be exactly the answer but the are hard to come by and as I remember expensive - it is not the best answer just and answer. The best answer is to find the length you need. But without understanding the gun I would not know where to start.

Se I just do not know enough about the gun

Me too.

I got lucky with a load for deer season, and did not have the time to play with it. Now that the hunting is over I can play around and see if I can make it better.

Ron is suggesting the 25 ACP conversion but I am not sure that would work with the primer carrier you describe. Normally you INSERT IGNORE the 25 acp directly into the BP plug, but again without experiance with the KRB - I do not know.

Are you done hunting now?

Another dumb question - with the gun closed and locked up can you get a feeler guage in between the block and the top of the primer?

Another left field thought can you some how measure from the back edge of the receiver to the top of the primer pocket?

If you can install the BP snug and a w209 primer bottomed in the pocket and get that measurement. Then back the BP out a little bit at a time until you get a snug lock up and get that measurement. That would tell you the shim thickness needed.

I still worry about the fact that the block is spring loaded instead of locked - it is always going to back away with blow back on the nose of the primer or even the inside of a 25 acp brass.

I keep going back to the fact that Knight constantly was trying to fight this war and did not come up with a real fix other than squeezing the flash hole.

Wish Idaho were closer to where ever you are.[/quote]